Abstract

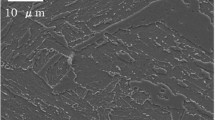

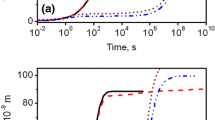

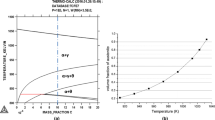

The nucleation and growth of austenite during continuous heating in plain carbon martensite is simulated using classical nucleation and diffusion growth theories assuming that austenite is nucleated on cementite particles at prior austenite grain boundaries and martensite packet, block, and interlath boundaries. A critical nucleus model on the spherical substrate was modified to take into account the influence of the boundary energy on which cementite particles formed. Simulations were carried out using the particle size distribution of cementite measured in an Fe-0.2 mass pct C alloy heated to near eutectoid temperature (Ae1). Austenite nucleation stopped in a very short time regardless of boundary site or particle size of cementite due to the fast decrease in carbon supersaturation and the depletion of nucleation sites. The fraction of austenite nucleated on cementite at prior austenite boundaries and martensite packet boundaries etc was much greater than that nucleated on cementite at interlath boundaries. While cementite particles dissolved quickly after austenite was nucleated, a large proportion of cementite particles at lath boundaries remained undissolved until they disappeared at 30 °C to 40 °C above Ae1. The evolution of austenite grain size was also simulated after austenitization was completed, and compared with experiment.

Similar content being viewed by others

References

R.F. Mehl and W.C. Hagel: Prog Met Phys 1956, vol. 6, pp. 74-134

R.R. Judd and H.W. Paxton: Trans TMS-AIME 1968, vol. 242, pp. 206-215

G.R. Speich and A. Szirmae: Trans TMS-AIME 1969, vol. 245, pp. 1063-1074

G.R. Speich, V.A. Demarest and R.L. Miller: Metall Trans A, 1981, vol. 12A, pp. 1419-1428

P.A. Wycliffe, G.R. Purdy and J.D. Embury: Canad Metall Quart 1981, vol.20, pp. 339-350

M. Enomoto and K. Hayashi: J Mater Sci 2015, vol. 50, pp. 6786-6793

M. Enomoto and K. Hayashi: J Mater Sci 2018, vol. 53, pp. 6911-6921.

F.J. Barbaro, P. Krauklis and K.E. Easterling: Mater Sci Tech 1989, vol. 5, pp. 1057-1068

H.I. Aaronson, M. Enomoto, J.K. Lee: Mechanisms of Diffusional Phase Transformations in Metals and Alloys, Ch.2 Diffusional Nucleation in Solid-Solid transformations, CRC Press, Taylor and Francis Group, Boca Raton, 2010.

J.K. Lee, J. H. Choy and Y. Choi: Surf Sci 1991, vol. 256, pp. 147-158

H.B. Aaron, D. Fainstein, G.R. Kotler: J Appl Phys 1970, vol. 41, pp. 4404-4410

M. Hillert: Acta Metall 1965, vol. 13, pp. 227-238

L.H. Van Vlack: Trans TMS-AIME, 1951, vol. 191, pp. 251-259

C.S. Smith: Trans ASM 1953, vol. 45, pp. 533-575

W.H. Beyer (ed) Standard Mathematical Tables. CRC Press, Boca Raton (1978)

J. Ågren: Acta Metall 1982, vol. 30, pp. 841-851

J. Ågren: Scripta Metall 1986, vol. 20, pp. 1507-1510

C. Qiu, S. van der Zwaag: Steel Res Int 1997, vol. 68, pp. 32–38

J. Ågren: Scand J Metall 1990, vol.19, pp. 2-8

L.J. Swartzendruber: Properties of Iron, in Phase Diagrams of Binary Iron Alloys, ed. H. Okamoto, ASM International, Metals Park, OH, 1993, p. 1

M. Perez: Scripta Mater 2005, vol. 52, pp. 709-712

S. Morito, H. Tanaka, R. Konishi, T. Furuhara and T. Maki: Acta Metall 2003, vol. 51, pp. 1789-1799

A.H. Pham, T. Ohba, S. Morito, T. Hayashi: J Alloys Comp 2013, vol. 5775, pp. 5583-5586

E.E. Underwood: in Quantitative stereology, ch 5, Addison-Wesley, Reading, Mass, 1970, pp. 109-135

W.F. Lang, III, M. Enomoto and H.I. Aaronson: Metall Mater Trans A 1988, vol. 19A, pp. 427-40

S.E. Offerman, N.H. Van Dijk, J. Sietsma, S. Grigull, E.M. Lauridsen, L. Margulies, H. F. Poulsen, M.Th. Rekveldt and S. Van der Zwaag: Science 2002, vol. 298, 1003-1005

H. Sharma: Ph.D thesis TU Delft, Ch. 6, 2012, pp. 151–86

H. Sharma, J. Sietsma and S. E. Offerman, Sci. Rep. 2016, https://doi.org/10.1038/srep30860

T. Shinozaki, Y. Tomota, T. Hukino, T. Suzuki, ISIJ International 2017, vol. 57, pp. 533-539

T. Nishizawa: Tetsu-to-Hagane 1984, vol. 70, pp. 194-202

M. Hillert: Metall Mater Trans A 1975, vol. 6A, pp. 5-19

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted July 10, 2019.

Rights and permissions

About this article

Cite this article

Enomoto, M., Hayashi, K. Simulation of Austenite Formation During Continuous Heating from Low Carbon Martensite with Poly-dispersed Cementite. Metall Mater Trans A 51, 618–630 (2020). https://doi.org/10.1007/s11661-019-05569-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05569-3