Abstract

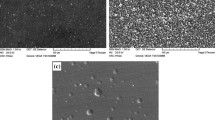

Ni-Mo coatings exhibit desirable corrosion and mechanical properties. Further improvements in their properties can significantly enhance their industrial applications. Reinforcing agents can be incorporated to address this priority. In the present investigation, Ni-Mo alloy and Ni-Mo-Y2O3 nanocomposite coatings were electrodeposited on the copper substrates to study the influences of Y2O3 nanoparticle content on the morphological, microstructural, mechanical, and corrosion properties of the coatings. Results exhibit that there is no change in the phase structure of the Ni-Mo alloy coatings with the incorporation of nanoparticles. Albeit the fact that introduction of the nanoparticles has no influence on the surface morphology of the coatings and all of the electrodeposited coatings show featureless morphology, there is a recognizable decrement in the number of surface-related defects such as pores, voids, and microcracks. Generally, mechanical and corrosion properties of the alloy coatings improve with nanoparticle embedment. Ni-Mo coating electrodeposited from a bath containing 3 g/L Y2O3 (Ni-Mo-3g/L Y2O3) shows the highest microhardness and corrosion resistance primarily originated from its higher Y2O3 content.

Graphic Abstract

Similar content being viewed by others

References

1. A. Rasooli, M.S. Safavi, and M.K. Hokmabad: Ceram. Int., 2018, vol. 44, pp. 6466–73.

M.S. Safavi and A. Rasooli: Surf. Eng., 2019, pp. 1–11.

3. M.S. Safavi and A. Rasooli: Surf. Coat. Technol., 2019, vol. 372, pp. 252–59.

4. M.S. Safavi, F. Babaei, A. Ansarian, and I. Ahadzadeh: Ceram. Int., 2019, vol. 45, pp. 10951–10960.

5. M. Alizadeh and H. Safaei: Appl. Surf. Sci., 2018, vol. 456, pp. 195–203.

6. E. Beltowska‐Lehman: Phys. Status Solidi C, 2008, vol. 5, pp. 3514–17.

7. M.S. Safavi and M. Etminanfar: JUFGNSM, 2019, vol. 52, pp. 1–17.

8. P.C. Huang, K.H. Hou, G.L. Wang, M.L. Chen, and J.R. Wang: Int. J. Electrochem. Sci., 2015, vol. 10, pp. 4972–84.

9. Q. Han, S. Cui, N. Pu, J. Chen, K. Liu, and X. Wei: Int. J. Hydrog. Energy, 2010, vol. 35, pp. 5194–5201.

10. E. Beltowska-Lehman, A. Bigos, P. Indyka, and M. Kot: Surf. Coat. Technol., 2012, vol. 211, pp. 67–71.

11. V.V. Kuznetsov, M.R. Pavlov, K.V. Kuznetsov, and V.N. Kudryavtsev: Russ. J. Electrochem., 2003, vol. 39, pp. 1338–41.

12. H.S. Yancheshmeh and M. Ghorbani: Surf. Coat. Technol., 2014, vol. 238, pp. 158–64.

13. P.C. Huang, K.H. Hou, H.H. Sheu, M.D. Ger, and G.L. Wang: Surf. Coat. Technol., 2014, vol. 258, pp. 639–45.

14. L.S Sanches, S.H. Domingues, C.E. Marino, and L.H. Mascaro: Electrochem. Commun., 2004, vol. 6, pp. 543–48.

15. Y. Zeng, Z. Li, M. Ma, and S. Zhou: Electrochem. Commun., 2000, vol. 2, pp. 36–38.

16. A. Laszczyńska, J. Winiarski, B. Szczygieł, and I. Szczygieł: Appl. Surf. Sci., 2016, vol. 369, pp. 224–31.

17. A. Laszczyńska, W. Tylus, J. Winiarski, and I. Szczygieł: Surf. Coat. Technol., 2017, vol. 317, pp. 26–37.

18. J. Niedbała: Mater. Sci. Forum, 2006, vol. 514, 465–69.

19. A. Rezaeiolum, M. Aliofkhazraei, A. Karimzadeh, A.S. Rouhaghdam, and R. Miresmaeili: Surf. Eng., 2018, vol. 34, pp. 423–32.

20. N.V. Krstajić, V.D. Jović, L. Gajić-Krstajić, B.M. Jović, A.L. Antozzi, and G.N. Martelli: Int. J. Hydrog. Energy, 2008, vol. 33, pp. 3676–87.

21. R. Abdel-Karim, J. Halim, S. El-Raghy, M. Nabil, and A. Waheed: J. Alloys Compd., 2012, vol. 530, pp. 85–90.

22. M. Allahyarzadeh, B. Roozbehani, and A. Ashrafi: Electrochim. Acta, 2011, vol. 56, pp. 10210–10216.

23. E. Chassaing, N. Portail, A.F. Levy, and G. Wang: J. Appl. Electrochem., 2004, vol. 34, pp. 1085–91.

24. S. Yagi, A. Kawakami, K. Murase, and Y. Awakura: Electrochim. Acta, 2007, vol. 52, pp. 6041–51.

25. R. Mousavi, K. Raeissi, and A. Saatchi: Int. J. Mod. Phys. B, 2008, vol. 22, pp. 3060–68.

26. H.S. Maharana, A. Ashok, S. Pal, and A. Basu: Metall. Mater. Trans. A, 2016, vol. 47A, pp. 388–99.

27. K. Mech: Metall. Mater. Trans. A, 2019, vol. 50A, pp. 1–13.

28. M. Uysal: Metall. Mater. Trans. A, 2019, vol. 50A, pp. 2331–41.

29. J.O. Nielsen, P. Møller, and K. Pantleon: Metall. Mater. Trans. A, 2019, vol. 50A, pp. 1–9.

30. S. Yang, X. Meng, J. Liu, C. Gui, and W. Xia: Metall. Mater. Trans. A, 2019, vol. 50A, pp. 1936–42.

31. D. Verma, D. Banerjee, and S.K. Mishra: Metall. Mater. Trans. A, 2019, vol. 50A, pp. 894–904.

32. S. Pal, R. Sarkar, and V. Jayaram: Metall. Mater. Trans. A, 2018, vol. 49A, pp. 3217–36.

33. N.P. Wasekar, P. Haridoss, and G. Sundararajan: Metall. Mater. Trans. A, 2018, vol. 49A, pp. 476–89.

34. M. Alizadeh and A. Cheshmpish: Appl. Surf. Sci., 2019, vol. 466, pp. 433–40.

35. P.D. Lima-Neto, A.N. Correia, G.L. Vaz, and P.N. Casciano: J. Braz. Chem. Soc., 2010, vol. 21, pp. 1968–76.

A.B. Radwan, K. Ali, R.A. Shakoor, H. Mohammed, T. Alsalama, R. Kahraman, M.M. Yusuf, A.M. Abdullah, M.F. Montemor, and M. Helal: Appl. Surf. Sci., 2018, vol. pp. 457 and 956–67.

37. E. Beltowska-Lehman and P. Indyka: Thin Solid Films, 2012, vol. 520, pp. 2046–51.

38. M. Donten, H. Cesiulis, and Z. Stojek: Electrochim. Acta, 2005, vol. 50, pp. 1405–12.

39. Y. Wang, S.L. Tay, S. Wei, C. Xiong, W. Gao, R.A. Shakoor, and R. Kahraman: J. Alloys Compd., 2015, vol. 679, pp. 222–28.

40. A.R. Madram, H. Pourfarzad, and H.R. Zare: Electrochim. Acta, 2012, vol. 85, pp. 263–67.

41. A.F. Zimmerman, G. Palumbo, K.T. Aust, and U. Erb: Mater. Sci. Eng. A, 2002, vol. 328, pp. 137–46.

42. N. Elkhoshkhany, A. Hafnway, and A. Khaled: J. Alloy Compd., 2017, vol. 695, pp. 1505–14.

43. C. Ma, S. Wang, and F. Walsh: Trans. IMF, 2015, vol. 93, pp. 8–17.

44. Y. Yang and Y. Cheng: Surf. Coat. Technol., 2011, vol. 205, pp. 3198–3204.

45. B. Bakhit and A. Akbari: Surf. Coat. Technol., 2012, vol. 206, pp. 4964–75.

46. C.N. Panagopoulos, E.P. Georgiou, A. Tsopani, and L. Piperi: Appl. Surf. Sci., 2011, vol. 257, pp. 4769–73.

47. B. Ranjith and G.P. Kalaignan: Appl. Surf. Sci., 2010, vol. 257, pp. 42–47.

48. L. Chang, H. Guo, and M. An: Appl. Surf. Sci., 2007, vol. 253, pp. 6085–89.

49. Y. Wang, B. Hu, S.L. Tay, F. Hou, W. Gao, and W. Chen: Int. J. Mod. Phys. B, 2017, vol. 31, p. 1744022.

50. B.S. Li and A. Lin: Key Eng. Mater., 2008, vol. 373, pp. 200–03.

51. B. Bakhit, A. Akbari, F. Nasirpouri, and M.G. Hosseini: Appl. Surf. Sci., 2014, vol. 307, pp. 351–59.

52. K. Zadeh, R. Shakoor, and A.B. Radwan: Int. J. Electrochem. Sci., 2016, vol. 11, pp. 7020–30.

53. I. García, A. Conde, G. Langelaan, J. Fransaer, and J.P. Celis: Corros. Sci., 2003, vol. 45, pp. 1173–89.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted July 16, 2019.

Rights and permissions

About this article

Cite this article

Fathi, M., Safavi, M.S., Mirzazadeh, S. et al. A Promising Horizon in Mechanical and Corrosion Properties Improvement of Ni-Mo Coatings Through Incorporation of Y2O3 Nanoparticles. Metall Mater Trans A 51, 897–908 (2020). https://doi.org/10.1007/s11661-019-05559-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05559-5