Abstract

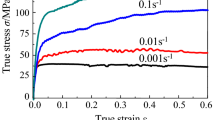

Based on the stress–strain curves of as cast Mg-8Gd-3Y alloy, which were obtained by isothermal compression tests at temperatures ranging from 350 °C to 450 °C and strain rates from 0.001 to 1.5 s−1, a new constitutive model for thermal deformation of magnesium alloys was proposed from the functional relationship between the ratio of instantaneous stress to peak stress (σ/σp) and that of instantaneous strain to peak strain (ε/εp). The undetermined parameters of the model were calculated through parameter regression, and the predicted results agree well with the experimental results. To study the applicability and accuracy of the new model, the stress–strain curves of the compression tests of AZ31B and ZK60 alloys in the literature were modeled and calculated by parameter regression, and their predicted values are very close to the experimental values. Then, the new constitutive model was integrated into a finite element software to simulate the load–stroke curves of isothermal upsetting of the specimen with variable cross-section and plane strain forging of Mg-8Gd-3Y alloy. Under six different process parameters, the simulated load–stroke curves are well consistent with the experimental curves. All the results verify the accuracy of the new model for thermal deformation of magnesium alloys.

Similar content being viewed by others

References

C. Meng, Z.K. Chen, H.N. Yang, G. Li, X.L. Wang and H. Bao: Metall. Mater. Trans. A, 2018, vol. 49A, pp. 5192–5204.

D. Ghosh, O.T. Kingstedt and G. Ravichaneran: Metall. Mater. Trans. A, 2017, vol. 48A, pp. 14–19.

H.C. Pan, F.H. Wang, M.L. Feng, L. Jin, J. Dong and P.D. Wu: Mater. Sci. Eng. A, 2018, vol. 712, pp. 585–91.

H.L. Chen, J. Yang, H. Zhou, J. Moering, Z. Yin, Y.L. Gong and K.Y. Zhao: Metall. Mater. Trans. A, 2017, vol. 48A, pp. 3961–70.

S.M. Fatemi, A. Zarei-Hanzaki and J.M. Cabrera: Metall. Mater. Trans. A, 2017, vol. 48A, pp. 2563–73.

J.Q. Li, J. Liu and Z.S. Cui: Mater. Sci. Eng. A, 2015, vol. 643, pp. 32–36.

M.Z. Bian, Z.R. Zeng, S.W. Xu, W.N. Tang, C.H.J. Davies, N. Birbilis and J.F. Nie: Metall. Mater. Trans. A, 2016, vol. 47A, pp. 5709–13.

Y.Y. Dong, C.S. Zhang, X. Lu, C.X. Wang and G.Q. Zhao: J. Mater. Eng. Perform., 2016, vol. 25, pp. 2567–81.

Y.J. Wang, J. Peng, L.P. Zhong and F.S. Pan: J. Alloys Compd., 2016, vol. 681, pp. 455–70.

W.T. Jia, S. Xu, Q.C. Le, L. Fu, L.F. Ma and Y. Tang: Mater. Des., 2016, vol. 106, pp. 120–32.

Y.J. Qin, Q.L. Pan, Y.B. He, W.B. Li, X.Y. Liu and X. Fan: Mater. Sci. Eng. A, 2010, vol. 527, pp. 2790–97.

H.T. Zhou, C.M. Liu and M.A. Chen: Mater. Sci. Tech., 2006, vol. 22, pp. 597–603.

Z.W. Cai, F.X. Chen and J.Q. Guo: J. Alloys Compd., 2015, vol. 648, pp. 215–22.

L.C. Tsao, Y.T. Huang and K.H. Fan: Mater. Des., 2014, vol. 53, pp. 865–69.

H. Takuda, T. Morishita, T. Kinoshita and N. Shirakawa: J. Mater. Process. Tech., 2005, vol. 164–165, pp. 1258–62.

J. Luan, C. Sun, X. Li and Q. Zhang: Mater. Sci. Technol., 2014, vol. 30, pp. 211–19.

M.S. Arun and U. Chakkingal: Mater. Sci. Eng. A, 2019, vol. 754, pp. 659–73.

H.T. Zhou, Q.B. Li, Z.K. Zhao, Z.C. Liu, S.F. Wen and Q.D. Wang: Mater. Sci. Eng. A, 2010, vol. 527, pp. 2022–26.

G.Z. Quan, Y. Shi, C.T. Yu and J. Zhou: Mater. Res., 2013, vol. 16, pp. 785–91.

Q. Tang, M.Y. Zhou, L.L. Fan, Y.W.X. Zhang, G.F. Quan and B. Liu: Vacuum, 2018, vol. 155, pp. 476–89.

Z.J. Wang, L.H. Qi, G. Wang, H.J. Li and M.S. Dargusch: Mech. Mater., 2016, vol. 102, pp. 90–96.

Mei RB, Bao L, Huang F, Zhang X, Qi XW, Liu XH (2018) Mech Mater 125:110–20

H. Yu, H.S. Yu, G. H. Min, S.S. Park, B.S. You and Y.M. Kim: Met. Mater. Int., 2013, vol. 19, pp. 651–65.

L. Li and X.M. Zhang: Mater. Sci. Eng. A, 2011, vol. 528, pp. 1396–1401.

Z.H. Zhou, Q.C. Fan, Z.H. Xia, A.G. Hao, W.H Yang, W. Ji and H.Q. Cao: J. Mater. Sci. Tech., 2017, vol. 33, pp. 637–44.

R. Alizadeh, R. Mahmudi, O.A. Ruano and A.H.W. Ngan: Metall. Mater. Trans. A, 2017, vol. 48A, pp. 5699–5709.

J.Q. Hao, J.S. Zhang, C.X. Xu and K.B. Nie: J. Alloys Compd., 2018, vol. 754, pp. 283–96.

Y. Sun, L.X. Hu and J.S. Ren: Mater. Charact., 2015, vol. 100, pp. 163–69.

S. He, C.S. Li, Z.Y. Huang and J.J. Zheng: J. Mater. Res., 2017, vol. 32, pp. 3831–41.

R. Bobbili and V. Madhu: Mater. Sci. Eng. A, 2017, vol. 700, pp. 82-91.

H.T. Zhou, X.Q. Zeng, Q.D. Wang and W.J. Ding: Acta Metall. Sin., 2004, vol. 17, pp. 155–60.

L.X. Xu, H.B. Wu and B.S. Xie: Mater. Sci. Technol., 2018, vol. 34, pp. 229–41.

Y. Bergstrom: Mater. Sci. Eng., 1970, vol. 5, pp. 193–200.

A. Laasraoui and J.J. Jonas: Metall. Trans. A, 1991, vol. 22A, pp. 151–60.

A. Laasraoui and J.J. Jonas: Metall. Trans. A, 1991, vol. 22A, pp. 1545–1558.

S. Serajzadeh and A.K. Taheri: Mech. Res. Commun., 2003, vol. 30, pp. 87–93.

J. Liu, Z.S. Cui and C.X. Li: Comp. Mater. Sci., 2008, vol. 41, pp. 375–82.

C. Wang, J. Liu and Z.S. Cui: J. Plast. Eng., vol. 18, pp. 22–27. (In Chinese)

L. Yuan, Z. Zhao, W.C. Shi, F.C. Xu and D.B. Shan: Int. J. Adv. Manuf. Technol., 2015, vol. 78, pp. 2037–47.

Y. Liu, C. Geng, Q.Q. Lin, Y.F. Xiao, J.R. Xu and W. Kang: J. Alloys Compd., 2017, vol. 713, pp. 212–21.

Z.P. Guan, M.W. Ren, P. Zhao, P.K. Ma and Q.L. Wang: Mater. Des., 2014, vol. 54, pp. 906–13.

H.T. Zhou, X.Q. Zeng, L.L. Liu, J. Dong, Q.D. Wang, W.J. Ding and Y.P. Zhu: Mater. Sci. Tech., 2004, vol. 20, pp. 1397–1402.

A.M.S. Hamouda: J. Mater. Process. Tech., 2002, vol. 124, pp. 209–15.

J. Liu, Z.S. Cui and C.X. Li: J. Mater. Process. Tech., 2008, vol. 205, pp. 497–505.

A. Hadadzadeh, M.A. Wells, S.K. Shaha, H. Jahed and B.W. Williams: J. Alloys Compd., 2017, vol. 702, pp. 274–89.

H.J. Hu, H. Wang, Z.Y. Zhai, Y.Y. Li, J.Z. Fan and Z.W. Qu: Int. J. Adv. Manuf. Technol., 2015, vol. 76, pp. 1621–30.

S.S. Zhou, K.K. Deng, J.C. Li, K.B. Nie, F.J. Xu, H.F. Zhou and J.F. Fan: Mater. Des., 2014, vol. 64, pp. 177–84.

Acknowledgments

The authors gratefully acknowledge the supports of the National Key Research and Development Program of China (Grant No. 2016YFB0301103), the National Natural Science Foundation of China (Grant No. 51601112), and the Shanghai Rising-Star Program (Grant Nos. 16QB1402800 and 17QB1403000).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted June 29, 2019.

Rights and permissions

About this article

Cite this article

Zeng, J., Wang, F., Wei, X. et al. A New Constitutive Model for Thermal Deformation of Magnesium Alloys. Metall Mater Trans A 51, 497–512 (2020). https://doi.org/10.1007/s11661-019-05528-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05528-y