Abstract

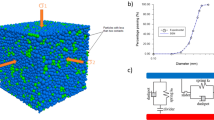

In this study, a continuum multiscale model based on discrete dislocation dynamics and viscoplastic self-consistent theory is developed. The model is capable of describing the macroscopic deformation behavior of polycrystalline metals and alloys, maintaining at the same time a microscopic level resolution that captures the dislocation density patterns within each grain. The continuum dislocation dynamics model is based on a set of nonlinear partial differential equations of the dislocation densities inside each grain. Three different types of dislocations, two mobile (positive and negative) and one immobile, are considered. The shear strain within each grain is calculated by the total dislocation density at every time step, and then linked to the viscoplastic self-consistent framework to calculate the macroscopic behavior of the polycrystalline material. At the same time, the dislocation density pattering within each grain, calculated by the evolution equations, is recorded to provide a local view of the material at grain level. For the purpose of demonstration, the focus of this paper is on polycrystalline Aluminum and the numerical solutions are compared with experimental data.

Similar content being viewed by others

References

J. Lubliner, Plasticity Theory, 1st ed. (Dover, Mineola, NY, 2008) pp 89--103

J.W. Yeh and S.J. Lin and T.S. Chin and J.Y. Gan and S.K. Chen and T.T. Shun and C. H. Tsau and S. Y. Chou: Metall. Mater. Trans. A, 2004, vol. 35, pp. 2533--2536.

D.R. Askeland, P.P. Fulay, and W.J. Wright: The Science and Engineering of Materials, 6th ed., Cengage Learning, Stamford, CT, 2011, pp. 113--155

D. Hull, D.J. Bacon, Introduction to dislocations, 5th ed. (Elsevier/Butterworth-Heinemann, Amsterdam, 2011) pp 1--21

H. Lyu and N. Taheri-Nassaj and H. M. Zbib: Philos. Mag., 2016, vol. 96, pp. 1883--1908.

E. Orowan: Proc. Phys. Soc., 1940, vol. 52(1), pp. 8--22.

H. Askari and M. R. Maughan and N. Abdolrahim and D. Sagapuram and D. F. Bahr and H. M. Zbib: Int. J. Plast., 2015, vol. 68, pp. 21--33.

H. Askari and J. P. Young and D. P. Field and G. Kridli and H. M. Zbib: Philosophical Magazine, 2014, 94, pp. 3353--3367.

D. Li and H. Zbib and X. Sun and M. Khaleel: Int. J. Plast., 2014, vol. 52, pp. 3--17.

H. Lyu and A. Ruimi and H. M. Zbib: Int. J. Plast., 2015, vol. 72, pp. 44--59.

O. Cazacu: Multiscale Modeling of Heterogenous Materials, 1st ed., Wiley, Hoboken, NJ, 2008, pp. 17--36

L. P. Evers and D. M. Parks and W. A. M. Brekelmans and M. G. D. Geers: J. Mech. Phys. Solids, 2002, vol. 50, pp. 2403--2424.

F. Roters and D. Raabe and G. Gottstein: Acta Mater., 2000, vol. 48, pp. 4181--4189.

T. Ohashi: Philos. Mag. Lett., 1997, vol. 75, pp. 51--58.

O. Rezvanian and M. Zikry and A. Rajendran: Mater. Sci. Eng. A, 2008, vol. 494, pp. 80--85.

A. Alankar and P. Eisenlohr and D. Raabe: Acta Mater., 2011, 59, pp. 7003--7009.

I. Beyerlein and C. Tomé: Int. J. Plast., 2008, vol. 24, pp. 867--895.

L. A. Zepeda-Ruiz and A. Stukowski and T. Oppelstrup and V. V. Bulatov: Nature, 2017, vol. 550, pp. 492--495.

M. Zaiser and M. C. Miguel and I. Groma: Phys. Rev. B, 2001, 64, pp. 224102.

M. Monavari and M. Zaiser: Mat. Th., 2018, 2, pp. 3.

H.A. Askari: PhD thesis, Washington State University, USA, 2014

S. Sandfeld and M. Monavari and M. Zaiser: Model. Simul. Mater. Sci. Eng., 2013, vol. 21, pp. 085006.

A. Arsenlis and D. M. Parks: Acta Mater., 1999, vol. 47, pp. 1597--1611.

D. Walgraef and E. C. Aifantis: Int. J. Eng. Sci., 1985, vol. 23, pp. 1351--1358.

D. Walgraef and E. C. Aifantis: Int. J. Eng. Sci., 1985, vol. 23, pp. 1359--1364.

D. Walgraef and E. C. Aifantis: Int. J. Eng. Sci., 1985, vol. 23, pp. 1365--1372.

H. Lim and M. G. Lee and J. H. Kim and B. L. Adams and R. H. Wagoner: Int. J. Plast., 2011, vol. 27, pp. 1328--1354.

R.K. AbuAl-Rub, G.Z. Voyiadjis, Int. J. Plast. vol. 20, pp. 1139--1182 (2004)

H. M. Zbib and M. Rhee and J. P. Hirth: Int. J. Mech Sci., 1998, vol. 40, pp. 113--127.

N. Taheri-Nassaj and H. M. Zbib: J. Eng. Mater. Technol., 2016, vol. 138, pp. 041015.

M. Monavari and S. Schmitt and S. Sandfeld: Proc. Appl. Math. Mech., 2013, vol. 13, pp. 263--264.

W.D. Callister: Materials science and engineering: an introduction, 7th ed. Wiley, New York, NY, 2007, pp 174--207

R. Asaro and A. Needleman: Acta Metall., 1985, vol. 33, pp. 923--953.

G. Taylor: Journal of the Institute of Metals, 1938, vol. 62, pp. 307--324.

G. I. Taylor: Proc. R. Soc. London Ser. A, 1934, vol. 145, pp. 362--387.

J. Bishop and R. Hill: Lond. Edinb. Dubl. Phil. Mag., 1951, vol. 42, pp. 414--427.

H. Wang, P. D. Wu, C. N. Tomé and Y. Huang: J. Mech. Phys. Solids, 2010, vol. 58, pp. 594--612.

R. A. Lebensohn and C. N. Tomé: Acta metall., 1993, vol. 41, pp. 2611--2624.

R. Lebensohn and C. N. Tomé: Mater. Sci. Eng., 1994, vol. 175, pp. 71--82.

G. Sachs: Z. Verein. Deut. Ing., 1928, vol. 72, pp. 734--736.

D. Raabe, F. Roters, F. Barlat, L.-Q. Chen, Continuum Scale Simulation of Engineering Materials: Fundamentals - Microstructures - Process Applications, 1st ed. (John Wiley and Sons, Berlin, Germany, 2004) pp 462--489

I. Simonovski, L. Cizelj, Grain-Scale Modeling Approaches for Polycrystalline Aggregates, 1st ed. (InTech, Rijeka, Croatia, 2012) pp 49--74

W. Gambin and F. Barlat: Int. J. Plast., 1997, vol. 13, pp. 75--85.

S. Ahzi and S. M’Guil and A. Agah-Tehrani: Mater. Sci. Forum, 2002, vol. 408, pp. 463--468.

S. Ahzi and S. M’Guil: Acta Mater., 2008, vol. 56, pp. 5359--5369.

A. Molinari and G. R. Canova and S. Ahzi: Acta Metall., 1987, vol. 35, pp. 2983--2994.

R. Hill: J. Mech. Phys. Solids, 1965, vol. 13, pp. 89--101.

J. D. Eshelby: Proc. Phys. Soc. Lond. Sec. A, 1957, vol. 241, pp. 376—396

R. J. Asaro: J. Appl. Mech., 1983, vol. 50, pp. 921--934.

F. Akasheh and H. M. Zbib and T. Ohashi: Philos. Mag., 2007, vol. 87, pp. 1307--1326.

T. Ohashi: Philos. Mag. A, 1994, vol. 70, pp. 793--803.

H. Lyu and A. Ruimi and D. P. Field and H. M. Zbib: Metall. and Mat. Trans. A, 2016, vol. 47, pp. 6608--6620.

E. O. Hall: Proc. Phys. Soc. Sec. B, 1951, vol. 64, pp. 747--753.

K. Hazeli and H. Askari and J. Cuadra and F. Streller and R. W. Carpick and H. M. Zbib and A. Kontsos: International Journal of Plasticity, 2015, 68, pp. 55--76.

R. Lebensohn, C. Tomé and P. Maudlin: J. Mech. Phys. Solids, 2004, vol. 52, pp. 249--278.

J. Jung and J. I. Yoon and J. H. Moon and H. K. Park and H. S. Kim: Comput. Mater. Sci., 2017, vol. 126, pp. 121--131.

A. Alankar and I. N. Mastorakos and D. P. Field: Acta Mater., 2009, vol. 57, pp. 5936--5946.

W. Hosford and R. Fleischer and W. Backofen: Acta Metall., 1960, vol. 8, pp. 187--199.

N. Tsuji and Y. Ito and Y. Saito and Y. Minamino: Scr. Mater., 2002, 47(12), pp. 893 -- 899.

Z. C. Cordero and B. E. Knight and C. A. Schuh: Int. Mater. Rev., 2016, 61(8), pp. 495--512.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted April 10, 2019.

Rights and permissions

About this article

Cite this article

Kermanshahimonfared, N., Askari, H. & Mastorakos, I. Plastic Behavior of Aluminum and Dislocation Patterning Based on Continuum Dislocation Dynamic (CDD). Metall Mater Trans A 51, 400–409 (2020). https://doi.org/10.1007/s11661-019-05512-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05512-6