Abstract

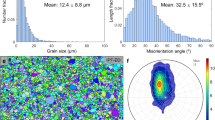

Twinning is an important deformation mechanism for Mg and other hexagonal metals. While twin nucleation is known to depend on the size and crystal orientation of the parent grain, so far there is no satisfactory criterion to predict twin nucleation in a polycrystalline Mg alloy prior to its deformation. In this work, machine learning is employed to tackle this problem. From a single-phase, polycrystalline Mg-0.47 wt pct Ca extruded alloy, three micro-tensile specimens, E-0, E-45, and E-90, were fabricated with their tensile axis being 0, 45, and 90 deg from the extrusion direction. Each specimen was deformed by 4 pct tensile strain in a scanning electron microscope. Six hundred thirty-six grains from E-0, 572 grains from E-45, and 840 grains from E-90 were characterized by electron backscattered diffraction (EBSD) before and after deformation. Twin nucleation was identified in 27, 150, and 220 grains in E-0, E-45, and E-90, respectively. Eighteen attributes that can influence twin nucleation, such as grain diameter, c-axis direction, and Schmid factors, were computed for each grain. Five machine learning algorithms, including decision tree, tree ensemble (XGBoost), artificial neural network (ANN), support vector machine (SVM), and naïve Bayes, were used to build models to predict twin nucleation according to a grain’s 18 attribute values, with E-45 as the training set and the other two specimens as the test sets. The ANN and SVM models show the best performance, both achieving ~ 87 pct prediction accuracy for specimens E-45 and E-90. None of the models perform well for E-0 because of the imbalanced class distribution in this specimen. The unpredicted twin nucleation events in E-90 mostly originate from triple junctions or twin–twin transmission at grain boundaries.

Similar content being viewed by others

References

J.W. Christian and S. Mahajan: Prog. Mater. Sci., 1995, vol.39, pp. 1-57.

J. Wang, J.P. Hirth, and C.N. Tome: Acta Mater., 2009, vol.57, pp. 5521-5530.

M.R. Barnett, Z. Keshavarz, A.G. Beer, and D. Atwell: Acta Mater., 2004, vol.52, pp. 5093-5103.

B. Clausen, C.N. Tome, D.W. Brown, and S.R. Agnew: Acta Mater., 2008, vol.56, pp. 2456-2468.

G. Proust, C.N. Tome, A. Jain, and S.R. Agnew: Int. J. Plast., 2009, vol.25, pp. 861-880.

H. Wang, P.D. Wu, J. Wang, and C.N. Tome: Int. J. Plast., 2013, vol.49, pp. 36-52.

C.H. Liu, L. Jin, J. Dong, and F.H. Wang: Materials & Design, 2016, vol.111, pp. 369-374.

A. Chakkedath, T. Maiti, J. Bohlen, S. Yi, D. Letzig, P. Eisenlohr, and C.J. Boehlert: Metall. Mater. Trans. A, 2018, vol.49, pp. 2441-2454.

C.D. Barrett, H. El Kadiri, and M.A. Tschopp: J. Mech. Phys. Solids, 2012, vol.60, pp. 2084-2099.

M.R. Barnett: Scripta Mater., 2008, vol.59, pp. 696-698.

L. Capolungo, P.E. Marshall, R.J. McCabe, I.J. Beyerlein, and C.N. Tome: Acta Mater., 2009, vol.57, pp. 6047-6056.

I.J. Beyerlein, L. Capolungo, P.E. Marshall, R.J. McCabe, and C.N. Tome: Phil. Mag., 2010, vol.90, pp. 2161-2190.

A. Ghaderi and M.R. Barnett: Acta Mater., 2011, vol.59, pp. 7824-7839.

C.N. Tome, I.J. Beyerlein, J. Wang, and R.J. McCabe: JOM, 2011, vol.63, pp. 19-23.

H. Somekawa and T. Mukai: Mater. Sci. Eng. A, 2013, vol.561, pp. 378-385.

M.A. Kumar, M. Wronski, R.J. McCabe, L. Capolungo, K. Wierzbanowski, and C.N. Tome: Acta Mater., 2018, vol.148, pp. 123-132.

J. Koike, Y. Sato, and D. Ando: Mater. Trans., 2008, vol.49, pp. 2792-2800.

I.J. Beyerlein, R.J. McCabe, and C.N. Tome: J. Mech. Phys. Solids, 2011, vol.59, pp. 988-1003.

J.J. Jonas, S.J. Mu, T. Al-Samman, G. Gottstein, L. Jiang, and E. Martin: Acta Mater., 2011, vol.59, pp. 2046-2056.

S.J. Mu, J.J. Jonas, and G. Gottstein: Acta Mater., 2012, vol.60, pp. 2043-2053.

A. Khosravani, D.T. Fullwood, B.L. Adams, T.M. Rampton, M.P. Miles, and R.K. Mishra: Acta Mater., 2015, vol.100, pp. 202-214.

Z.Z. Shi, Y.D. Zhang, F. Wagner, P.A. Juan, S. Berbenni, L. Capolungo, J.S. Lecomte, and T. Richeton: Acta Mater., 2015, vol.83, pp. 17-28.

L. Wang, Y. Yang, P. Eisenlohr, T.R. Bieler, M.A. Crimp, and D.E. Mason: Metall. Mater. Trans. A, 2010, vol.41, pp. 421-430.

L. Wang, P. Eisenlohr, Y. Yang, T.R. Bieler, and M.A. Crimp: Scripta Mater., 2010, vol.63, pp. 827-830.

L. Wang, R. Barabash, T. Bieler, L. Wenjun, and P. Eisenlohr: Metall. Mater. Trans. A, 2013, vol.44, pp. 3664-3674.

D. Guan, B. Wynne, J. Gao, Y. Huang, and W. Rainforth: Acta Mater., 2019, 170, 1-14.

X. Hong, A. Godfrey, and W. Liu: Scripta Mater., 2016, vol.123, pp. 77-80.

P. Raccuglia, K.C. Elbert, P.D.F. Adler, C. Falk, M.B. Wenny, A. Mollo, M. Zeller, S.A. Friedler, J. Schrier, and A.J. Norquist: Nature, 2016, vol.533, pp. 73-77.

R. Ramprasad, R. Batra, G. Pilania, A. Mannodi-Kanakkithodi, and C. Kim: npj Comput. Mater., 2017, 3, 54.

Y. Zhang and C. Ling: npj Comput. Mater., 2018, 4, 25.

A. Agrawal and A. Choudhary: APL Materials, 2016, vol.4, 053202.

A. Rovinelli, M.D. Sangid, H. Proudhon, and W. Ludwig: npj Comput. Mater., 2018, 4, 35.

S.R. Kalidindi and M. De Graef: Annu. Rev. Mater. Res., 2015, vol 45, pp. 171-193.

B.L. DeCost, T. Francis, and E.A. Holm: Acta Mater., 2017, vol.133, pp. 30-40.

W. Li, K.G. Field, and D. Morgan: npj Comput. Mater., 2018, 4, 36.

A. Mangal and E.A. Holm: Int. J. Plast., 2018, vol.111, pp. 122-134.

A. Mangal and E.A. Holm: Int. J. Plast., 2019, vol.114, pp. 1-14.

A.D. Orme, I. Chelladurai, T.M. Rampton, D.T. Fullwood, A. Khosravani, M.P. Miles, and R.K. Mishra: Comp. Mater. Sci., 2016, vol.124, pp. 353-363.

D.M.W. Powers: J. Mach. Learning Technol., 2, 37-63 (2007)

P.N. Tan, M. Steinbach, and V. Kumar: Introduction to Data Mining, Pearson, New York, 2005.

T. Chen and C. Guestrin: XGBoost: A Scalable Tree Boosting System. ACM, San Francisco, 2016, pp. 785-794.

Acknowledgments

This work is financially supported by the National Natural Science Foundation of China (Nos. 51671127 and 51631006) and a collaborative research project (No. 18X120010001) between the University of Michigan and Shanghai Jiao Tong University that applies data science to Mg alloy design. We thank Dr. Kai Yu for valuable discussions about machine learning. X.Z. also acknowledges the support from the Science and Technology Commission of Shanghai Municipality (Grant No. 16DZ2260600).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted June 22, 2019.

Rights and permissions

About this article

Cite this article

Tong, Z., Wang, L., Zhu, G. et al. Predicting Twin Nucleation in a Polycrystalline Mg Alloy Using Machine Learning Methods. Metall Mater Trans A 50, 5543–5560 (2019). https://doi.org/10.1007/s11661-019-05468-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05468-7