Abstract

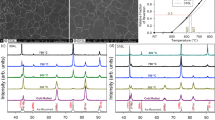

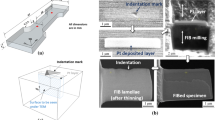

The roles of grain size, texture, strain, and strain rate on the thermal and mechanical stability of austenite in AISI 321 metastable austenitic stainless steel were studied. Ultrafine grain (UFG), fine grain (FG), and coarse grain (CG) specimens with average grain sizes of 0.24, 3, and 37 µm sizes, respectively, were investigated. To determine the thermal stability of austenite (TSA), samples were soaked in liquid nitrogen (− 196 °C) for varying times between 0.5 and 24 hours. On the other hand, the mechanical stability of austenite (MSA) was studied by subjecting cylindrical specimens to both quasi-static (4.4 × 10−3 s−1) and dynamic loading conditions (between 1300 and 8800 s−1). Thermally-induced α′-martensite was only observed at an incumbent time in AISI 321 to suggests an isothermal martensitic transformation occurred. Both Kurdjumov-Sachs (\( \{ 111\}_{\gamma } ||\{ 110\}_{{\alpha^{\prime}}} \) and \( \langle \bar{1}01\rangle_{\gamma } ||\langle 1\bar{1}1\rangle_{{\alpha^{\prime } }} \)) and Nishiyama–Wasserman (\( \{ 111\}_{\gamma } ||\{ 110\}_{{\alpha^{\prime}}} \) and \( \langle 112\rangle_{\gamma } ||\langle 011\rangle_{{\alpha^{\prime } }} \)) orientation relationships existed between the untransformed γ and thin-plate α′-martensite. The thermally-induced phase transformation was highly suppressed in UFG specimens. While TSA decreased with an increase in grain size, MSA decreased with a decrease in grain size. While thin-plate α′ predominantly formed in the thermally-treated AISI 321 steel (FG and CG specimens only), lath and irregularly-shaped α′ formed in the specimens deformed under quasi-static and dynamic loading conditions, respectively. Irrespective of strain rate, deformation-induced α′ in UFG specimens inherited the morphology of the deformed austenite grain that is equiaxed. Irrespective of grain size, MSA also decreased with increase in strain (up to a critical strain for specimens deformed under dynamic loading condition) and decrease in strain rate. In the event of adiabatic shear band (ASB) formation in a specimen deformed at high strain rate, MSA increased as the ASB was approached due to the temperature rise in the ASB region. Electron backscattered diffractometry examination revealed that the evolution of both thermally- and deformation-induced martensite is orientation-dependent in FG and CG specimens. The instability (thermal and mechanical) of the austenite phase is highest in the RD/CD||[100]-oriented grains (RD and CD are rolling and compression directions, respectively), followed by grains oriented near RD/CD||[110] and RD/CD||[111], in that order. These findings could open a new window of engineering the initial texture of metastable austenitic stainless steel to either aid thermally and/or mechanically-stable austenite phase or promote both isothermal and deformation-induced martensitic phase transformation.

Similar content being viewed by others

References

J. Y. Choi, T. Fukuda, and T. Kakeshita: Mater. Sci. Forum, 2010, vol. 654–656, pp. 130–133.

P. R. Rios and J. R. C. Guimarães: Mater. Res., 2016, vol. 19, pp. 490–495.

H. Zheng, W. Wang, D. Wu, S. Xue, Q. Zhai, J. Frenzel, and Z. Luo: Intermetallics, 2013, vol. 36, pp. 90–95.

T. Kakeshita, T. Saburi,K. Shimizu: Philos. Mag. B Phys. Condens. Mater. 2000, vol. 80, pp. 171–181.

E. Yasar, E. Güler, H. Güngünes, and T. N. Durlu: Mater. Charact., 2008, vol. 59, pp. 769–772.

T. Kakeshita, K. Kuroiwa, K. Shimizu, T. Ikeda, A. Yamagishi, and M. Date: Mater. Trans. JIM, 1993, vol. 34, pp. 423–428.

D. E. Laughlin, N. J. Jones, A. J. Schwartz, and T. B. Massalski: Int. Conf. Martensitic Transform. 2008, 2013, pp. 141–144.

J. M. Nam, T. Terai, and T. Kakeshita: J. Alloys Compd., 2013 vol. 577, pp. S348–S352.

I. Y. Georgieva; and I. I. Nikitina: Met Sci Heat Treat, 1972, vol. 5, pp. 68–72.

D. Z. Yang and C. M. Wayman: Scr. Metall., 1983, vol. 17, pp. 1377–1379.

M. B. Leban and R. Tisu: Eng. Fail. Anal., 2013, vol. 33, pp. 430–438.

K. Spencer, J. D. Embury, K. T. Conlon, M. Véron, and Y. Bréchet: Mater. Sci. Eng. A, 2004, vol. 387–389, pp. 873–881.

P. R. Rios, G. SilvaDrumond, T. Neves, J. R. C. Guimarães: Mater. Sci. Forum (2014), 783, pp. 2182–2187.

A. A. Tiamiyu, J. A. Szpunar, A. G. Odeshi, I. Oguocha, M. Eskandari: Metall. Mater. Trans. A, 2017, vol. 48, pp. 5990–6012.

C. Weinong and S. Bo: Split Hopkinson (Kolsky) Bar: Design, Testing and Applications (Mechanical Engineering Series), Illustrate. New York: Springer Science & Business Media, 2010.

J. Talonen, P. Aspegren, and H. Hänninen: Mater. Sci. Technol., 2004, vol. 20, pp. 1506–1512.

Y. F. Shen, N. Jia, Y. D. Wang, X. Sun, L. Zuo, and D. Raabe: Acta Mater., 2015, vol. 97, pp. 305–315.

H. F. G. DeAbreu, S. S. DeCarvalho, P. DeLimaNeto, R. P. DosSantos, V. N. Freire, P. M. D. O. Silva, and S. S. M. Tavares: Mater. Res., 2007, vol. 10, pp. 359–366.

H.K.D.H. Bhadeshia and R.W.K. Honeycombe: in Steels: Microstructure and Properties, Third edition, Butterworth-Heinemann, Boston, 2006, pp. 95–128.

Y. Matsuoka, T. Iwasaki, N. Nakada, and T. Tsuchiyama: ISIJ Int., 2013, vol. 53, pp. 1224–1230.

Y. L. Chang, P. Y. Chen, Y. T. Tsai, and J. R. Yang: Mater. Charact., 2016, vol. 113, pp. 17–25.

L. Bracke, K. Verbeken, L. Kestens, and J. Penning: Acta Mater., 2009, vol. 57, pp. 1512–1524.

H. Y. Lee, H. W. Yen, H. T. Chang, and J. R. Yang: Scr. Mater., 2010, vol. 62, pp. 670–673.

T. Maki: in Phase Transformations in Steels, Woodhead Publishing, Oxford, 2012, pp. 34–58.

M. Umemoto, E. Yoshitake, and I. Tamura: J. Mater. Sci., 1983, vol. 18, pp. 2893–2904.

A. Shibata, T. Murakami, S. Morito, T. Furuhara, and T. Maki: Mater. Trans., 2008, vol. 49, pp. 1242–1248.

S. Kajiwara and W. S. Owen: Scr. Metall., 1977, vol. 11, pp. 137–142.

N. N. Thadhani and M. A. Meyers: Prog. Mater. Sci., 1986, vol. 30, pp. 1–37.

A. A. Tiamiyu, A. G. Odeshi, and J. A. Szpunar: Mater. Sci. Eng. A, 2018, vol. 711, pp. 233–249.

A. Kundu and P. C. Chakraborti: J. Mater. Sci., 2010, vol. 45, pp. 5482–5489.

J. A. Lichtenfeld, M. C. Mataya, and C. J. Van Tyne: Metall. Mater. Trans. A, 2006, vol. 37, pp. 147–161.

T. Iwamoto, T. Sawa, and M. Cherkaoui: Int. J. Mod. Phys. B, 2008, vol. 22, pp. 5985–5990.

J. Talonen, H. Hänninen, P. Nenonen, and G. Pape: Metall. Mater. Trans. A, 2005, vol. 36, pp. 421–432.

A. Das and S. Tarafder: Int. J. Plast., 2009, vol. 25, pp. 2222–2247.

H. Yen, S. W. Ooi, M. Eizadjou, A. Breen, C. Huang, H. K. D. H. Bhadeshia, and S. P. Ringer: Acta Mater., 2015, vol. 82, pp. 100–114.

A. A. Tiamiyu, V. Tari, J. A. Szpunar, A. G. Odeshi, and A. K. Khan: Int. J. Plast., 2018, vol. 107, pp. 79–99.

W. S. Choi, S. Sandlöbes, N. V. Malyar, C. Kirchlechner, S. Korte-Kerzel, G. Dehm, B. C. De Cooman, and D. Raabe: Acta Mater., 2017, vol. 132, pp. 162–173.

L. Wang, J.C. Eknfs, Y. Cai, F. Zhao, D. Fan, and S.N. Luo: J. Appl. Phys., 2015, vol. 117, pp. 084301.

M. Karlsen, O. Grong, M. Søfferud, J. Hjelen, G. Rørvik, and R. Chiron: Metall. Mater. Trans. A, 2009, vol. 40, pp. 310–320.

H. Zhan, W. Zeng, G. Wang, D. Kent, and M. Dargusch: Mater. Charact., 2015, vol. 102, pp. 103–113.

J. Peirs, W. Tirry, B. Amin-Ahmadi, F. Coghe, P. Verleysen, L. Rabet, D. Schryvers, and J. Degrieck: Mater. Charact., 2013, vol. 75, pp. 79–92.

V. F. Nesterenko, M. A. Meyers, J. C. LaSalvia, M. P. Bondar, Y. J. Chen, and Y. L. Lukyanov: Mater. Sci. Eng. A, 1997, vol. 229, pp. 23–41.

Acknowledgments

Authors wish to acknowledge the financial support of Natural Sciences and Engineering Research Council of Canada (NSERC). A.A. Tiamiyu acknowledges the financial support provided by the Vanier Canada Graduate Scholarship for this study. The support of ACUREN Group Inc. for the use of Fischer Feritscope MP30E is well appreciated.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted January 3, 2019.

Rights and permissions

About this article

Cite this article

Tiamiyu, A.A., Zhao, S., Li, Z. et al. Thermal and Mechanical Stability of Austenite in Metastable Austenitic Stainless Steel. Metall Mater Trans A 50, 4513–4530 (2019). https://doi.org/10.1007/s11661-019-05362-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05362-2