Abstract

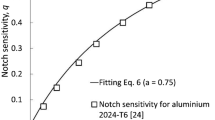

The as-built surfaces of metallic parts made by additive manufacturing (AM) processes often contain notch-like features that serve as stress concentration sites where fatigue crack nucleation may occur. These notch-like features, which result from the surface roughness inherent to AM processes, should be considered in assessing the fatigue performance of AM parts. In this investigation, a methodology for predicting surface crack nucleation in AM materials has been developed by considering (1) the stress concentration factors (kt) associated with the surface micro-notches, (2) the cycles to surface crack nucleation, and (3) the threshold stress ranges for the growth or non-growth of the microcracks. The combination of the micro-notch and low-cycle fatigue (LCF) life model, named micro-LCF model, shows that there exists a minimum surface roughness profile, defined in terms of a ratio of valley depth (Rvi) to valley spacing (λi) of 0.01, below which fatigue life debit does not occur. Furthermore, fatigue crack nucleation and growth dominates at Rvi/λi < 0.18 and fatigue crack nucleation with non-propagating cracks prevails at Rvi/λi > 0.18 and kt > 1.5. A surface roughness with an Rvi/λi ratio = 1 and kt = 3 is also identified as the worst-case condition where fatigue life is entirely controlled by crack growth. This methodology has been applied to a nickel-based superalloy AM 718Plus to confirm the various ways in which surface roughness affects surface crack nucleation and growth. In addition, potential fatigue life enhancement that can be achieved by machining portions, if not all, of the as-built surfaces is assessed.

Similar content being viewed by others

References

S. Das, M. Wohlert, J.J. Beaman, and D.L. Bourell: JOM, 1998, vol. 50, pp. 17-20.

W.E. Frazier: J. & Mater. Eng. Performance, 2014, vol. 23, pp. 1917-1928.

P.A. Kobryn and S.L. Semiatin: JOM, 2001, vol. 53, pp. 40-42.

P.A. Kobryn and S.L. Semiatin: Proceedings of the 12th Solid Freeform Fabrication Symposium, 2001, Austin, TX, pp. 179–86.

L.E. Murr, S.M. Gaytan, F. Medina, E. Martinez, D.H. Hernandez, L. Martinez, M.I. Lopez, R.B. Wicker, and S. Collins: Proceedings of the 20th International Solid Freeform Symposium, 2009, Austin, TX, pp. 374–97.

L.E. Murr, S.M. Gaytan, A. Ceylan, E. Martinez, J.L. Martinez, D.H. Hernandez, B.I. Machado, D.A. Ramirez, F. Medina, S. Collins, and R.B. Wicker: Acta Mater., 2010, vol. 58, pp. 1887-1894.

L. Thijs, F. Verhaeghe, T. Craeghs, J. Van Humbeeck, and J-P. Kruth: Acta Mater., 2010, vol. 58, pp. 3303–12.

E. Brandl, C. Leyens, and F. Palm: Trends in Aerospace Manufacturing 2009 International Conference, IOP Conference Series: Materials Science and Engineering, 2011, vol. 26, 012004, IOP Publishing.

E. Brandl, U. Heckenberger, V. Holzinger, and D. Buchbinder: Materials and Design, 2012, vol. 34, pp. 159-169.

L.E. Murr, E.V. Esquivel, S.A. Quinones, S.M. Gaytan, M.I. Lopez, E.Y. Martinez, F. Medina, D.H. Hernandez, E. Martinez, J.L. Martinez, S.W. Stafford, D.K. Brown, T. Hoppe, W. Meyers, U. Lindhe, and R.B. Wicker: Mater. Charact., 2009, vol. 60, pp. 96-105.

L.E. Murr, S.A. Quinones, S.M. Gaytan, M.I. Lopez, A. Rodela, E.Y. Martinez, D.H. Hernandez, E. Martinez, F. Medina, and R.B. Wicker: J. Mech. Behav. Biomed. Mater., 2009, vol. 2, pp. 20-32.

G.V. Joshi, Y. Duan, J. Neidigh, M.I. Koike, G. Chahine, R. Kovacevic, T. Okabe: J. Dent. Res., 2010, vol. 89 (Spec Iss B), p. 213.

E. Amsterdam and G.A. Kool: ICAF 2009, Bridging the Gap Between Theory and Operational Practice, Part 8, 2009, pp. 1261-1274.

J. Alcisto, A. Enriquez, H. Garcia, S. Hinkson, T. Steelman, E. Silverman, P. Valdovino, H. Gigerenzer, J. Foyos, J. Ogren, J. Dorey, K. Karg, T. McDonald, and O.S. Es-Said: J. Mater. Eng. Perform., 2011, vol. 20(2), pp. 203-212.

M. Koike, P. Greer, K. Owen, L.E. Murr, S.M. Gaytan, E. Martinez, and T. Okabe: Materials 2011, vol. 4(10), pp. 1776-1792.

G. Strano, L. Hao, R.M. Everson, and K.E. Evans: Journal of Material Processing Technology, 2013, vol. 213, pp. 589-597.

T. Grimm, G. Wiora, and G. Witt: Surface Topography: Metrology. Properties, 2015, vol. 3, 014001.

E. Brinksmeier, G. Levy, and A.B. Spierings: CIRP Annals—Manufacturing Technology, 2010, vol. 59(1), pp. 601–06.

K.S. Chan, M. Koike, R.L. Mason, and T. Okabe: Metallurgical and Materials Transactions A, 2013, vol. 44(2), pp. 1010-1022.

P. Edwards and M. Ramulu: Mat.Sci. Eng., 2014, vol. 598, pp. 327-337.

A. Mostafa, I.P. Rubio, V. Brailovski, M. Jahazi, and M. Medraj: Metals, 2017, vol. 7, paper 197, pp. 1–23.

J. Gong, H.Z. Deutchman, A. Peralta, D. Snyder, M.P. Enright, J. McFarlad, J. Neuman, J. Sebastian, and G. Olson: Integrated Thermal Process Optimization of Alloy 718Plus for Additive Manufacturing, Superalloy 16: Proceedings of the 13th Int. Sym. Of Superalloys, edited by M. Hardy, E. Huron, U. Glatzel, B. Griffin, B. Lewis, C. Rae, V. Seetharaman, and S. Tin, TMS, Warrendale, PA, 2016.

K.S. Chan: Surface Topography: Metrology and Properties, vol. 3, 2015, 044006; https://doi.org/10.1088/2051-672x/3/4/044006

J. C. Sobotka and R. C. McClung: Proceedings of the ASTM Symposium on Structural Integrity of Additive Manufactured Parts, ASTM STP 1620, 2018 (In Press).

Honeywell Aerospace Inc., DARPA Open Manufacturing Program Phase 3, Contract Number HR0011-12-C-0037, 2018.

R.E. Peterson: Stress Concentration Factors, John Wiley and Sons, New York, 1974.

W.D. Pilkey, Peterson’s Stress Concentration Factors, 2nd Edition. Wiley, New York, NY, 1997, pp. 20–24.

J. Telesman, T.P. Gabb, Y. Yamada, and S.L. Drapper: Mater. High Temp. https://doi.org/10.1080/09603409.2016.1179000

K.S. Chan: International Journal of Fatigue, 2010, vol. 32, pp. 1428-1447.

S.J. Hudak Jr., K.S. Chan, G.G. Chell, Y-D. Lee, and R.C. McClung, Proceedings of David L. Davidson Symposium on Fatigue, edited by K.S. Chan, P.K. Liaw, R.S. Bellows, T.C. Zogas, and W.O. Soboyejo, TMS, Warrendale, PA, 2002, pp. 107–20.

M.H. El Haddad, K.N. Smith, and T.H. Topper: ASME J. Eng. Mat. Tech., 1979, vol. 101, pp. 42-46.

Acknowledgments

This work was supported by Honeywell Aerospace Inc. as parts of the work funded by the DARPA Opening Manufacturing Program Phase 3 through Contract No. HR0011-12-C-0037 (Jan Vandenbrande, Program Manager) through a subcontract (Purchase Order 3502009562E) to Southwest Research Institute (SwRI) from Honeywell. The clerical assistance of Ms. Loretta Mesa, SwRI, in the preparation of the manuscript is acknowledged. The views, opinions, and/or findings expressed are those of the author and should not be interpreted as representing the official views or policies of the Department of Defense or the U.S. Government.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted February 19, 2019.

Distribution A: Approved for public release, distribution unlimited.

Rights and permissions

About this article

Cite this article

Chan, K.S., Peralta-Duran, A. A Methodology for Predicting Surface Crack Nucleation in Additively Manufactured Metallic Components. Metall Mater Trans A 50, 4378–4387 (2019). https://doi.org/10.1007/s11661-019-05309-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05309-7