Abstract

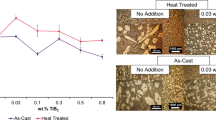

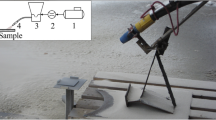

The cavitation erosion resistance was increased several times after the surface of nodular cast iron EN-GJS-400-15 samples was melted using an industrially inexpensive process (TIG—Tungsten Inert Gas) to generate a layer with a white cast iron microstructure that contributes to the improvement of the wear resistance. Using currents of 60, 70, 80, and 90 A at an approximately constant voltage of 9.5 to 10 V, the process led to the complete or partial dissolution of graphite nodules and to the resolidification of the liquid in primary austenitic dendrites (that undergo further decomposition into ferrite and cementite) and into interdendritic ledeburitic acicular eutectic. The analysis of the TIG surface-melted samples tested for cavitation erosion showed a ductile-type fracture of the surface and a decrease of 2.2 to 3.9 times of the maximum erosion penetration depth and 1.9 to 3.2 times the erosion rate compared to the heat-treated reference material annealed to relieve stress. Rapid cooling of the melted surface and the formation of a large amount of eutectic cementite instead of graphite created fine microstructures that contributed to the increase in hardness and consequently to a better resistance to cavitation erosion of the TIG surface-melted samples compared to the one of the base gray cast iron.

Similar content being viewed by others

References

1. S. Hattori and T. Kitagawa: Wear, 2010, vol. 269, nos. 5-6, pp. 443-8.

2. K.P. Balan, A.V. Reddy, V. Joshi, and G. Sundararajan: Wear, 1991, vol. 145, pp. 283-96.

3. T. Okada, Y. Iwai, and A. Yamamoto: Wear, 1983, vol. 84, pp. 297-312.

4. W.J. Tomlinson, J.H.P.C. Megaw, A.S. Bransden, and M. Girardi: Wear, 1987, vol. 116, no. 2, pp. 249-60.

5. S.P. Gadag and M.N. Srinivasan: J. Mater. Process. Technol., 1995, vol. 51, nos. 1-4, pp. 150–63.

6. K.Y. Benyounis, O.M.A. Fakron, J.H. Abboud, A.G. Olabi, and M.J.S. Hashmi: J. Mater. Process. Technol., 2005, vol. 170, pp. 127-32.

7. L.C. Chang, I.C. Hsui, L.H. Chen, and T.S. Lui: Wear, 2004, vol. 257, pp. 1125-32.

R. Arabijeshvaghani, M. Shamanian, and M. Jaberzadeh: Mater. Des., 2011, vol. 32, pp. 2028-33.

9. I. Mitelea, I. Bordeaşu, M. Pelle, and C.M. Crăciunescu: Ultrasonic Sonochem., 2015, vol. 23, pp. 385-90.

10. M.S. Heydarzadeh, G. Karshenas, and S.M. Boutorabi: J. Mater. Process. Technol., 2004, vols. 153–154, pp. 199-202.

11. M. Jean and Y. Tzeng: Int. J. Adv. Manuf. Technol., 2004, vol. 24, pp. 190-8.

12. A. Gulzar, J.I. Akhter, M. Ahmad, G. Ali, M. Mahmood, and M. Ajmal: Appl. Surf. Sci., 2009, vol. 255, pp. 8527-32.

13. K.Y. Benyounis, O.M. Fakron, and J.H. Abboud: Mater. Design, 2009, vol. 30, pp. 674-8.

14. A. Roy and I. Manna: Mater. Sci. Eng. A, 2001, vol. 279, pp. 85-93.

15. K.F. Alabeedi, J.H. Abboud, and K.Y. Benyounis: Wear, 2009, vol. 266, pp. 925-33.

16. C.H. Chen, C.P. Ju, and J.M. Rigsbee: Mater. Sci. Technol., 1988, vol. 4, p. 161.

17. A. Amirsadeghi and M.S. Heydarzadeh: J. Mater. Process. Technol., 2008, vol. 201, pp. 673-7.

A. Amirsadeghi, M.S. Heydarzadeh, and S.F. Kashanibozorg: J. Iron Steel Res. Int., 2008, vol. 15, pp. 86-94.

19. T. Ishida: J. Mater. Sci., 1983, vol. 18, pp. 1773-84.

20. W.S. Dai, L.H. Chen, and T.S. Lui: Wear, 2001, vol. 248, pp. 201-10.

M. Shamanian, S.M.R. Mousaviabarghouie, and S.R. Mousavi: Mater. Design, 2010, vol. 31, pp. 2760-6.

*** Standard test method for cavitation erosion using vibratory apparatus ASTM G32-2010.

23. I. Mitelea, C. Ghera, I. Bordeaşu, and C. Crăciunescu: Trans. ASME, 2018, vol. 140, pp. 1-13.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted May 8, 2019.

Rights and permissions

About this article

Cite this article

Mitelea, I., Bena, T., Bordeasu, I. et al. Enhancement of Cavitation Erosion Resistance of Cast Iron with TIG Remelted Surface. Metall Mater Trans A 50, 3767–3775 (2019). https://doi.org/10.1007/s11661-019-05287-w

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05287-w