Abstract

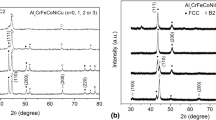

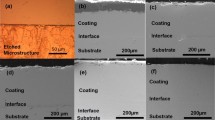

Although dilute Cu-Cr alloys are frequently used for applications involving sliding contacts, their wear mechanism at elevated temperatures has rarely been explored. We fabricated a bulk Cu-6 wt pct Cr alloy using high-energy ball milling and spark plasma sintering, and systematically investigated its dry sliding wear behavior against 440C stainless steel at room temperature and 300 °C. The alloy had a heterogeneous microstructure consisting of coarse-grained Cu (average grain size: 1.5 µm) distributed into a nanocrystalline Cu-Cr matrix (average Cu grain size: 77 nm; Cr-rich precipitate size: 18 nm), which gave high strength and plasticity (ultimate compressive strength: 1020 MPa; strain-to-failure: 26.0 pct) at room temperature. At 300 °C, the strength was significantly reduced, the coefficient of friction and wear rate increased, and the dominant wear mode switched from adhesive wear to oxidative/abrasive wear. Uniformly distributed nanoscale Cr-rich and Cr oxide precipitates hindered severe plastic deformation near the sliding surface during wear at room temperature; at 300 °C, severe plastic deformation was observed, with elongated Cu grains and uniformly dispersed Cr-rich and Cr oxide nanoparticles. Formation of a discontinuous glaze layer consisting of equiaxed nanograins of Cu, Cu oxides, and Cr oxides resulted in severe abrasion-assisted wear, and reduced the wear resistance at 300 °C.

Similar content being viewed by others

References

G. Purcek, H. Yanar, O. Saray, I. Karaman, and H.J. Maier: Wear, 2014, vol. 311, pp. 149-58.

I.S. Batra, G.K. Dey, U.D. Kulkarni, and S. Banerjee: J. Nucl. Mater., 2001, vol. 299, pp. 91-100.

N. Takata, Y. Ohtake, K. Kita, K. Kitagawa, and N. Tsuji: Scripta Mater., 2009, vol. 60, pp. 590-93.

H. Nagasawa and K. Kato: Wear, 1998, vol. 216, pp. 179-83.

Q. Fang, Z.X. Kang, Y.W. Gan, and Y. Long: Mater. Des., 2015, vol. 88, pp. 8-15.

G. Purcek, H. Yanar, D.V. Shangina, M. Demirtas, N.R. Bochvar, and S.V. Dobatkin: J. Alloy. Compd., 2018, vol. 742, pp. 325-33.

R.K. Gautam, S. Ray, S.C. Sharma, S.C. Jain, R. Tyagi (2011) Wear, 271: 658-64.

A.K. Shukla, R.S. Kumar, S.V.S.N. Murty, K. Mondal (2013) Mater. Sci. Eng. A 577: 36-42

J.P. Tu, W.X. Qi, Y.Z. Yang, F.Liu, J.T. Zhang, G.Y. Gan, N.Y. Wang, X.B. Zhang, and M.S. Liu: Wear, 2001, vol. 249, pp. 1021-27.

Y. Zhang, A.A. Volinsky, H.T. Tran, Z. Chai, P. Liu, B.H. Tian, Y. Liu (2016) Mater. Sci. Eng. A 650:248-53.

N.Y. Tang, D.M. R. Taplin, and G.L. Dunlop: Mater. Sci. Technol., 1985, vol. 1, pp. 270-75.

T. Fujii, H. Nakazawa, M. Kato, and U. Dahmen: Acta Mater., 2000, vol. 48, pp. 1033-45.

F.X. Huang, J.S. Ma, H.L. Ning, Z.T. Geng, C. Lu, S.M. Guo, X.T. Yu, T. Wang, H. Li, and H.F. Lou: Scripta Mater., 2003, vol. 48, pp. 97-102.

P. Liu, J. Su, Q. Dong, and H. Li: J. Mater. Sci. Technol., 2005, vol. 21, pp. 475-78.

H.T. Zhou, J.W. Zhong, X. Zhou, Z.K. Zhao, and Q.B. Li: Mater. Sci. Eng. A, 2008, vol. 498, pp. 225-30.

J.H. Su, Q.M. Dong, P. Liu, H.J. Li, and B.X. Kang: Mater. Sci. Eng. A, 2005, vol. 392, pp. 422-26.

Z.L. Zhang, J.M. Guo, G. Dehm, and R. Pippan: Acta Mater. 2017, vol. 138, pp. 42-51.

J.M. Guo, J.L. Rosalie, R. Pippan, and Z.L. Zhang: Scripta Mater., 2017, vol. 133, pp. 41-44.

A. Bachmaier, G.B. Rathmayr, M. Bartosik, D. Apel, Z. Zhang, and R. Pippan: Acta Mater., 2014, vol. 69, pp. 301-13.

A. Vinogradov, V. Patlan, Y. Suzuki, K. Kitagawa, and V.I. Kopylov: Acta Mater., 2002, vol. 50, pp. 1639-51.

R. Mishnev, I. Shakhova, A. Belyakov, and R. Kaibyshev: Mater. Sci. Eng. A, 2015, vol. 629, pp. 29-40.

K.X. Wei, W. Wei, F. Wang, Q.B. Du, I.V. Alexandrov, and J. Hu: Mater. Sci. Eng. A, 2011, vol. 528, pp. 1478-84.

K.V. León, M.A. Muñoz-Morris, and D.G. Morris: Mater. Sci. Eng. A, 2012, vol. 536, pp. 181-89

M. Kulczyk, B. Zysk, M. Lewandowska, K.J. Kurzydłowski: Phys. Status Solidi A, 2010, vol. 207, pp. 1136-38.

C. Aguilar, V.D.P. Martinez, J. M. Palacios, S. Ordoñez, and O. Pavez: Scripta Mater., 2007, vol. 57, pp. 213-16.

Q. Fang and Z.X. Kang: Powder Technol., 2015, vol. 270, pp. 104-11.

S.H. Dong, C.L. Zhang, L.Y. Zhang, J. Cai, P. Lv, Y.X. Jin, and Q.F. Guan: J. Alloy. Compd., 2018, vol. 755, pp. 251-56.

I. Lahiri and S. Bhargava: Powder Technol., 2009, vol. 189, pp. 433-38.

G. Lee, E.A. Olevsky, C. Manière, A. Maximenko, O. Izhvanov, C. Back, and J. McKittrick: Acta Mater.,2018, vol. 144, pp. 524-33.

K.B. Gerasimov, S.V. Mytnichenko, S.V. Pavlov, V.A. Chernov, and S.G. Nikitenko: J. Alloy. Compd., 1997, vol. 252, pp. 179-83.

S. AsadiKouhanjani, A. ZareBidaki, and A. Akbari: J. Alloy. Compd., 2009, vol. 486, pp. 319-24.

S. AsadiKouhanjani, A. ZareBidaki, M. Abedini, and N. Parvin: J. Alloy. Compd., 2009, vol. 480, pp. 505-09.

W.X. Qi, J.P. Tu, F. Liu, Y.Z. Yang, N.Y. Wang, H.M. Lu, X.B. Zhang, S.Y. Guo, and M.S. Liu: Mater. Sci. Eng. A, 2003, vol. 343, pp. 89-96.

J.F. Curry, T.F. Babuska, T.A. Furnish, P. Lu, D.P. Adams, A.B. Kustas, B.L. Nation, M.T. Dugger, M. Chandross, B.G. Clark, B. L. Boyce, C.A. Schuh, and N. Argibay: Adv. Mater., 2018, vol. 30, p. 1870242.

X. Chen, Z. Han, X.Y. Li, and K. Lu: Sci. Adv., 2016, vol. 2, p.e1601942.

D.A. Rigney: Wear, 2000, vol. 245, pp. 1-9.

K.J. Chu, J. Zhou, and F.Z. Ren: Wear, 2018, vol. 414-415, pp. 251-61.

J.R. Jiang, F.H. Stott, and M.M. Stack: Wear, 1995, vol. 181-183, pp. 20-31.

F.H. Stott, D.S. Lin, G.C. Wood, and C.W. Stevenson: Wear, 1976, vol. 36, pp. 147-74.

J. Jiang, F.H. Stott, and M.M. Stack: Wear, 1997, vol. 203, pp. 615-25.

A. Pauschitz, M. Roy, and F. Franek: Tribol. Int., 2008, vol. 41, pp. 584-602.

C. Rynio, H. Hattendorf, J. Klöwer, and G. Eggeler: Wear, 2014, vol. 315, pp. 1-10.

E. Ma: Prog. Mater. Sci., 2005, vol. 50, pp. 413-509.

C. Suryanarayana: Prog. Mater. Sci., 2001, vol. 46, pp. 1-184.

A.P. Zhilyaev and T.G. Langdon: Prog. Mater. Sci., 2008, vol. 53, pp. 893-979.

A. Takeuchi and A. Inoue: Mater. Trans., 2005, vol. 46, pp. 2817-29.

P. Hvizdoš, M. Besterci, and P. Kulu: High Temp. Mater. Process., 2011, vol. 30, p 573-77.

S. Mula, P. Sahani, S.K. Pratihar, S. Mal, and C.C. Koch: Mater. Sci.Eng. A, 2011, vol. 528, pp. 4348-56.

P. Sahani, S. Mula, P.K. Roy, P.C. Kang, and C.C. Koch: Mater. Sci.Eng. A, 2011, vol. 528, pp. 7781-89.

S. Bera, S.G. Chowdhury, W. Lojkowsky, and I. Manna: Mater. Sci. Eng. A, 2012, vol. 558, pp. 298-308.

F.Z. Ren, W.W. Zhu, K.J. Chu, and C.C. Zhao: J. Alloy. Compd., 2016, vol. 676, pp. 164-72.

G. Straffelini, L. Maines, M. Pellizzari, and P. Scardi: Wear, 2005, vol. 259, pp. 506-11.

J. Don, T. C. Sun, and D. A. Rigney: Wear, 1983, vol. 91, pp. 191-99.

F. Ren, S.N. Arshad, P. Bellon, R.S. Averback, M. Pouryazdan, and H. Hahn: Acta Mater., 2014, vol. 72, pp. 148-58.

S. Kang: Wear, 1993, vol. 162-164, pp. 1123-28.

A. Emge, S. Karthikeyan, and D.A. Rigney: Wear, 2009, vol. 267, pp. 562-67.

W. Cai and P. Bellon: Acta Mater., 2012, vol. 60, pp. 6673-84.

J.B. Singh, W. Cai, and P. Bellon: Wear, 2007, vol. 263, pp. 830-41.

W. Cai and P. Bellon: Wear, 2013, vol. 303, pp. 602-10.

I.A. Inman, S.R. Rose, and P.K. Datta: Wear, 2006, vol. 265, pp. 1592-1605.

G.W. Stachowiak and A.W. Batchelor: in Engineering Tribology (Third Edition), ed. G.W. Stachowiak and A.W. Batchelor, eds., Butterworth-Heinemann, Burlington, 2006, pp. 573–93.

F F.H. Stott: Tribol. Int., 1998, vol. 31, pp. 61-71.

M.B. Peterson, S.F. Murray, and J.J. Florek: ASLE Trans., 1959, vol. 2, pp. 225-34.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (Grant No. 51874204), and the Fundamental Research Program of Shenzhen (Grant Nos. JCYJ20170412153039309 and JCYJ20170307110418960).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted November 8, 2018.

Rights and permissions

About this article

Cite this article

Pan, S., Zhao, C., Zhu, W. et al. Sliding Wear Behavior of Spark Plasma-Sintered Cu–6 Wt Pct Cr Alloy at Room and Elevated Temperatures. Metall Mater Trans A 50, 3132–3147 (2019). https://doi.org/10.1007/s11661-019-05243-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05243-8