Abstract

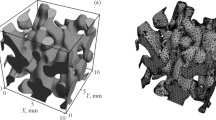

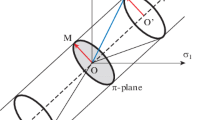

This article proposes an extended Ramberg–Osgood (R–O) relationship accounting for the effect of porosity on porous metal behavior under tension. Initially, microstructural unit cells satisfying continuity boundary conditions were employed to account for pore intensity and its effect on elastic-plastic behavior. Results obtained from micromechanical simulations coupled with regression analyses were utilized to express elastic-plastic behavior as a function of porosity. Therefore, mathematical relationships were successfully developed to extend the R–O model to account for porosity. Finally, for validation and assessment of the developed relation, analytical and macromechanical finite element (FE) results were compared with those of testing. Comparisons at low-porosity range, i.e., < 10 pct, proved to have excellent agreement. It is concluded that multiscale FE analyses conducted successively on the micro- and macro-scales efficiently delineated the effect of porosity on mechanical behavior. Moreover, these analyses enabled extending the R–O relationship for accurate modeling of porous metals with low-range porosity.

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings are within the manuscript.

References

M. Attaran: Bus. Horiz., 2017, vol. 60, pp. 677–88.

W.E. Frazier: J. Mater. Eng. Perform., 2014, vol. 23, pp. 1917–28.

P.G. Allison, H. Grewal, Y. Hammi, H.R. Brown, W.R. Whittington, and M.F. Horstemeyer: J. Eng. Mater. Technol., 2013, vol. 135, p. 041008.

J.A. Choren, S.M. Heinrich, and M.B. Silver-Thorn: J. Mater. Sci., 2013, vol. 48, pp. 5103–12.

N. Soro, L. Brassart, Y. Chen, M. Veidt, H. Attar, and M.S. Dargusch: Mater. Sci. Eng. A, 2018, vol. 725, pp. 43–50.

H. Zaharin, A. Abdul Rani, F. Azam, T. Ginta, N. Sallih, A. Ahmad, N. Yunus, T. Zulkifli, H.A. Zaharin, A.M. Abdul Rani, F.I. Azam, T.L. Ginta, N. Sallih, A. Ahmad, N.A. Yunus, and T.Z.A. Zulkifli: Materials, 2018, vol. 11, p. 2402.

I. Gibson, D. Rosen, and B. Stucker: Rapid Manuf. Assoc., 2013, pp. 10–2.

B.A. Szost, S. Terzi, F. Martina, D. Boisselier, A. Prytuliak, T. Pirling, M. Hofmann, and D.J. Jarvis: Mater. Des., 2016, vol. 89, pp. 559–67.

R.A. Hardin and C. Beckermann: Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2013, vol. 44, pp. 5316–32.

F. Wang, S. Williams, P. Colegrove, and A.A. Antonysamy: Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2013, vol. 44, pp. 968–77.

Y.J. Cao, W.Q. Shen, J.F. Shao, and N. Burlion: Eur. J. Mech. / A Solids, 2018, vol. 72, pp. 407–23.

R.A. Hardin and C. Beckermann: in Proceedings of the 65th SFSA technical and Operating Conference, Steel Founders’ Society of America, Chicago, IL, 2011.

S.J. Polasik, J.J. Williams, and N. Chawla: 2002, vol. 33, pp. 73–81.

J.M. Dewey: J. Appl. Phys., 1947, vol. 18, pp. 578–81.

J.N. GOODIER: T. A. S. M. E., 1933, vol. 55, p. 39.

D.P.H. HASSELMAN: J. Am. Ceram. Soc., 1962, vol. 45, pp. 452–3.

D.P.H. HASSELMAN: J. Am. Ceram. Soc., 1963, vol. 46, pp. 564–5.

K.K. Phani: J. Mater. Sci. Lett., 1986, vol. 5, pp. 747–50.

C.W. Bert: J. Mater. Sci., 1985, vol. 20, pp. 2220–4.

R.M. SPRIGGS: J. Am. Ceram. Soc. Notes, 1961, vol. 28, pp. 1960–1.

J.P. Panakkal, H. Willems, and W. Arnold: J. Mater. Sci., 1990, vol. 25, pp. 1397–402.

F.P. KNUDSEN: J. Am. Ceram. Soc., 1959, vol. 42, pp. 376–87.

A.L. Gurson: J. Eng. Mater. Technol., 1977, vol. 99, p. 2.

V. Tvergaard and A. Needleman: Acta Metall., 1984, vol. 32, pp. 157–69.

Abaqus Documentation, Dassault Systèmes, Providence, Rhode Island, 2014.

A. Schiavone, G. Abeygunawardana-Arachchige, and V. V. Silberschmidt: Acta Mech., 2016, vol. 227, pp. 203–15.

Y. Oh, H. Nam, Y. Kim, and N. Miura: Int. J. Press. Vessel. Pip., 2018, vol. 159, pp. 35–44.

J. Oliver, M. Caicedo, A.E. Huespe, J.A. Hernández, and E. Roubin: Comput. Methods Appl. Mech. Eng., 2017, vol. 313, pp. 560–95.

F. Roters, P. Eisenlohr, L. Hantcherli, D.D. Tjahjanto, T.R. Bieler, and D. Raabe: Acta Mater., 2010, vol. 58, pp. 1152–211.

A.A. Gusev: J. Mech. Phys. Solids, 1997, vol. 45, pp. 1449–59.

T. Mori and K. Tanaka: Acta Metall., 1973, vol. 21, pp. 571–4.

K. Miled, K. Sab, and R. Le Roy: Mech. Res. Commun., 2011, vol. 38, pp. 131–5.

S.L. Omairey, P.D. Dunning, and S. Sriramula: Eng. Comput., 2018, vol. 0, pp. 1–11.

A. Trofimov, S. Abaimov, I. Akhatov, and I. Sevostianov: Int. J. Eng. Sci., 2018, vol. 123, pp. 117–26.

S.A. Elnekhaily and R. Talreja: Compos. Sci. Technol., https://doi.org/10.1016/j.compscitech.2017.11.017.

S.J. Hollister and N. Kikuchi: Comput. Mech., 1992, vol. 10, pp. 73–95.

L.E.. Dæhli, J. Faleskog, T. Børvik, and O.S. Hopperstada: Procedia Struct. Integr., 2016, vol. 2, pp. 2535–42.

L.E. Bryhni Dæhli, J. Faleskog, T. Børvik, and O.S. Hopperstad: Eur. J. Mech. A/Solids, 2017, vol. 65, pp. 360–83.

M. Eudier: Otolaryngol. Neck Surg., 1962, vol. 9, pp. 278–90.

R.E. FRYXELL and B.A. CHANDLER: J. Am. Ceram. Soc., 1964, vol. 47, pp. 283–91.

D.P.H. HASSELMAN and R.M. FULRATH: J. Am. Ceram. Soc., 1964, vol. 47, pp. 52–3.

W. Ramberg and W.R. Osgood: Description of Stress-Strain Curves by Three Parameters, 1943.

H. Ghayoor, S. V. Hoa, and C.C. Marsden: Compos. Part B Eng., https://doi.org/10.1016/j.compositesb.2017.09.009.

X. Deng, G. Piotrowski, N. Chawla, and K.S. Narasimhan: 2008, vol. 491, pp. 19–27.

N. Chawla, J.J. Williams, and R. Saha: 2003, vol. 2, pp. 215–27.

R.A. Hardin and C. Beckermann: Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2007, vol. 38A, pp. 2992–3006.

J.R. Nimmo: Encycl. Soils Environ., 2004, pp. 295–303.

N. Chawla and X. Deng: Mater. Sci. Eng. A, 2005, vol. 390, pp. 98–112.

R.I. Stephens, J.J. Horn, D.D. Poland, and E.A. Sager: Eff. Prod. Qual. Des. Criteria Struct. Integrity, STP1337-EB, 1998, pp. 72–101.

J.W. Cain: Mol. Life Sci., 2017, pp. 1–7.

Acknowledgments

This work is sponsored by the President’s Doctoral Student Investment Fund (PDSIF) at Memorial University of Newfoundland and Natural Sciences and Engineering Research Council of Canada (NSERC) and Discovery Grant Program (NSERC DG No. 210415). This support is gratefully acknowledged.

Conflict of interest

None.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted February 12, 2019.

Rights and permissions

About this article

Cite this article

Elruby, A.Y., Nakhla, S. Extending the Ramberg–Osgood Relationship to Account for Metal Porosity. Metall Mater Trans A 50, 3121–3131 (2019). https://doi.org/10.1007/s11661-019-05236-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05236-7