Abstract

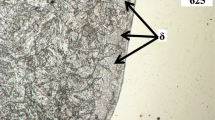

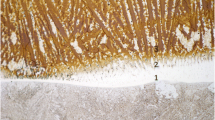

High base metal dilution (50 pct) dissimilar metal weld between A508 low-alloy steel and 309L clad layer was fabricated to investigate the effect of extended post-weld heat treatment (PWHT) on microstructure and mechanical properties. Extended PWHT at 607 °C caused significant carbon migration and microstructural change across the fusion boundary. Following PWHT at 607 °C for 20 hours, the carbon-enriched zone exhibited little to no reduction in hardness although 20 pct hardness reduction occurred in the remainder of the first butter layer. This is because tempering of the martensite in the carbon-enriched zone was entirely offset by the formation of a high density of chromium carbides. In contrast, following PWHT at 607 °C for 20 hours the average hardness of the carbon-depleted zone decreased from 241 HV to 169 HV due to the elimination of martensite, ferrite grain coarsening and carbon depletion. In addition, the extended PWHT significantly enhanced the mismatch in mechanical properties between the carbon-enriched zone (351 HV) and the adjacent carbon-depleted zone (169 HV). The formation of chromium carbides (less than 200 nm in size) in the carbon-enriched zone reduced the carbon concentration in the matrix, generating a continued driving force for carbon migration from A508 steel to the weld metal during PWHT.

Similar content being viewed by others

References

C.D. Lundin: Weld. J., 1982, vol. 61, pp. S58-S63.

T.W. Nelson, J.C. Lippold, M.J. Mills: Weld. J., 1999, vol 78, pp. 329S-37S.

J.N. DuPont: Int. Mater. Rev., 2012, vol. 57, pp. 208-34.

J.N. Dupont, S. Babu, S. Liu: Metall. and Mater. Trans. A, 2013, vol. 44A, pp. 3385-410.

T.W. Nelson, J.C. Lippold, M.J. Mills: Sci. Technol. Weld. J., 1998, vol. 3, pp. 249-55.

H.L. Ming, R.L. Zhu, Z.M. Zhang, J.Q. Wang, E.H. Han, W. Ke, M.X. Su: Mater. Sci. Eng. A, 2016, vol. 669, pp. 279-90.

T. Helander, J. Agren, J.O. Nilsson: Isij Inter., 1997, vol. 37, pp. 1139-45.

Y.Y. You, R.K. Shiue, R.H. Shiue, C. Chen: J. Mater Sci. Lett., 2001, vol. 20, pp. 1429-32.

D.W. Rathod, S. Pandey, S. Aravindan, P.K. Singh: Metall. Micro. Anal., 2016, vol. 5, pp. 450-60.

H.L. Ming, Z.M. Zhang, J.Q. Wang, E.H. Han, W. Ke: Mater. Charact., 2014, vol. 97, pp. 101-15.

K.W. Andrew: J. Iron Steel Ins., 1985, vol. 203, pp. 721-27.

M.L. Huang and L. Wang: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 3037-46.

M. Ghosh, R. Santosh, S.K. Das, G. Das, B. Mahato, J. Korody, S. Kumar, P.K. Singh, Metall. Mater. Trans. A, 2015, vol. 46A, pp. 3555-68.

J.A. Siefert, J.P. Shingledecker, J.N. DuPont, S.A. David: Sci. Tech. Weld. Join.. 2016. vol. 21. pp. 397-428.

Acknowledgments

The authors also acknowledge Electric Power Research Institute (EPRI) for financial support. The authors also acknowledge the experimental and analytical support provided by Quentin Allen, Qi Wu, Paul Minson, and Professor Michael Dorais.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted October 12, 2018.

Rights and permissions

About this article

Cite this article

Liu, F.C., Nelson, T.W. & McCracken, S.L. Effect of Post-weld Heat Treatment on Microstructure and Mechanical Properties of Dissimilar Metal Weld Used in Power Plants. Metall Mater Trans A 50, 2826–2834 (2019). https://doi.org/10.1007/s11661-019-05223-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05223-y