Abstract

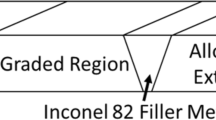

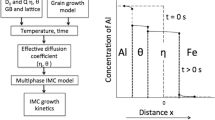

Dissimilar metal welds between ferritic and austenitic alloys are common in high-temperature applications in the energy industry. Under service conditions, these welds experience carbon diffusion and concomitant detrimental microstructural changes that can render them susceptible to premature creep failure. Therefore, it is helpful to identify a filler metal and joint design to reduce the driving force of carbon diffusion and prolong the expected service life. In the current investigation, thermodynamic modeling was used to identify candidate alloys that reduce the chemical potential gradient, which is the driving force for carbon diffusion. Additionally, diffusion modeling was used to determine an optimal grade length for a graded transition joint to further reduce the extent of carbon diffusion. A graded transition joint was fabricated and aged to understand the microstructural evolution, and the results were used for direct comparison with the observed trends from the model simulations. It was determined that increasing the grade length to the millimeter length scale reduced the extent of carbon diffusion by an order of magnitude when compared to a conventional dissimilar metal weld with a concentration gradient on the length scale of ~ 10-100 microns. Additionally, a step function composition gradient was implemented into the diffusion calculations to simulate the more realistic gradients produced with additive manufacturing processes. In these stepped gradients, enhanced carbon diffusion occurred at the layer interfaces, indicating important regions that undergo microstructural evolution. The experimentally observed carbide distribution in the characterized graded transition joints is in good agreement with the calculated carbide distribution.

Similar content being viewed by others

References

R.L. Klueh and J.F. King: Weld. J., 1982, vol. 61, pp. 302–11.

J.N. DuPont: Int. Mater. Rev., 2012, vol. 57, pp. 208–34.

R. Dooley and P. Chang: Proceedings of the International Conference on Boiler Tube Failures in Fossil, 1997, pp. 2–10.

K. Laha, K.S. Chandravathi, K.B.S. Rao, S.L. Mannan, and D.H. Sastry: Metall. Mater. Trans. a, 2001, vol. 32A, pp. 115–24.

C.D. Lundin: Weld. J., 1982, p. 58s–63s.

J.D. Parker and G.C. Stratford: Sci. Technol. Weld. Join., 1999, vol. 4, pp. 29–39.

B Nath: Weld. Technol. Energy Appl., 1982. Vol. 1982, pp. 597–621

J.D. Parker and G.C. Stratford: Mater. Sci. Eng. A, 2001, vol. 299, pp. 164–73.

J.D. Parker and G.C. Stratford: Mater. Sci. Eng. A, 2001, vol. 299, pp. 174–84.

R.J. Christoffel and M.R. Curran: Weld. J., 1956, vol. 35. 529–540

D.A. Porter, K.E. Easterling, and M.Y. Sherif: Phase Trasformations in Metals and Alloys, Third., Taylor and Francis Group, 2009.

L. S. Darken: Metall. Mater. Trans. B 1948, vol. 41, pp. 543–562

J.F. Eckel: Weld. J., 1964, vol. 43, pp. 170–178

M. Gittos and T. Gooch: Weld. Res. Suppl., 1992, vol. 71, pp. 461–72.

C. Sudha, V.T. Paul, A.L.E. Terrance, S. Saroja, and M. Vijayalakshmi: Weld. J., 2006, vol. 85, p. 71 s–80 s.

R. Anand, C. Sudha, V.T. Paul, S. Saroja, and M. Vijayalakshmi: Suppl. to Weld. J., 2010, vol. 89, pp. 65–74.

K. Laha, S. Latha, K.B.S. Rao, S.L. Mannan, and D.H. Sastry: Mater. Sci. Technol., 2001, vol. 17, pp. 1265–72.

G.J. Brentrup, J.N. DuPont, B.S. Snowden, and J.L. Grenestedt: Weld. J, 2012, vol. 91, pp. 252–59

N. Sridharan, E. Cakmak, B. Jordan, D. Leonard, W.H. Peter, R.R. Dehoff, D. Gandy, and S.S. Babu: Weld. J., 2017, vol. 96, p. 295 s–306 s.

J.O. Andersson, T. Helander, L. Hoglund, P.F. Shi, and B. Sundman: Calphad, 2002, vol. 26, pp. 273–312.

Thermo-Calc Software TCFE7-TCS Steels/Fe-Alloys Database version 7.

Thermo-Calc Software Ni-Data-v7 Ni-Alloys Database.

J.N. Dupont and A.R. Marder: Metall. Mater. Trans. B, 1996, vol. 27B, pp. 481–9.

A. Borgenstam, L. Höglund, J. Ågren, and A. Engström: J. Phase Equilibria, 2000, vol. 21, pp. 269–80.

Thermo-Calc Software MOB2 TCS Alloy Mobility Database.

R.L. Klueh: Metall. Trans. A, 1978, vol. 9, pp. 1591–8.

J.D. Parker and G.C. Stratford: J. Mater. Sci., 2000, vol. 35, pp. 4099–107.

Y. Zhou, Y. Li, Y. Liu, Q. Guo, C. Liu, L. Yu, C. Li, and H. Li: J. Mater. Res., 2015, vol. 30, pp. 3642–52.

H. Larsson: Calphad, 2014, vol. 47, pp. 1–8.

H. Larsson and L. Höglund: CALPHAD Comput. Coupling Phase Diagrams\penalty\z@\protect\futurelet\@let@token Thermochem., 2009, vol. 33, pp. 495–501.

J.O. Andersson, T. Helander, L. Höglund, P. Shi, and B. Sundman: Calphad Comput. Coupling Phase Diagrams Thermochem., 2002, vol. 26, pp. 273–312.

S.W. Banovic, J.N. Dupont, and A.R. Marder: Weld. J., 2001, vol. 80, pp. 63–70.

G.J. Brentrup and J.N. DuPont: Weld. J., 2013, vol. 92, pp. 72–9.

D. Drouin, A.R. Couture, D. Joly, X. Tastet, V. Aimez, and R. Gauvin: 2007, vol. 29, pp. 92–101.

J.N. Dupont: Microstructural Characterization and Modeling of Dissimilar Weld Failures Involving Grade 91, 2016.

J. Shingledecker, K. Coleman, J. Siefert, J. Tanzosh, and W. Newell: in 9th Liege Conference: Materials for Advanced Power Engineering 2010, J. Lecomte-Beckers, Q. Contrepois, T. Beck, and B. Kuhn, eds., Germany, 2010.

A.L. Schaeffler: Met. Prog., 1949, vol. 56, p. 680.

S.K. Albert, T.P.S. Gill, A.K. Tyagi, S.L. Mannan, S.D. Kulkarni, and P. Rodriguez: Weld. J., 1997, vol. 66, pp. 135–42.

39 J.F. King, M.D. Sullivan, and G.M. Slaughter: Weld. J., 1977, vol. 56, pp. 354–8.

R.D. Nicholson: Met. Technol. 1984, vol. 11, pp. 115–24.

J.N. Dupont and C.S. Kusko: Weld. J., 2007, vol. 86, p. 51.

S. Suresh: Prog. Mater. Sci., 1997, vol. 42, pp. 243–51.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted May 30, 2018.

Rights and permissions

About this article

Cite this article

Galler, J.P., DuPont, J.N., Babu, S.S. et al. Design of Graded Transition Joints Through Thermodynamic and Kinetic Modeling. Metall Mater Trans A 50, 2765–2783 (2019). https://doi.org/10.1007/s11661-019-05186-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05186-0