Abstract

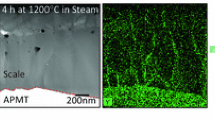

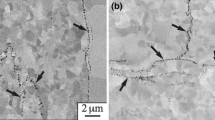

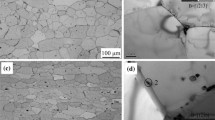

FeCrAl ferritic steels containing dispersed Al2O3 particles instead of Y2O3 or Ce2O3 particles were developed for accident-tolerant fuel cladding in light-water reactors. Forcible addition of only oxygen through mechanical alloying can create Al2O3 particles by precipitation during annealing above 973 K. The oxygen content was controlled to use oxidation of internal aluminum to form Al2O3 particles and increase the number density of Al2O3 particles with an average diameter of around 40 nm. The size and number density of Al2O3 particles are significantly affected by lattice misfit, and thus interfacial energy between Al2O3 particles and the matrix, and by aluminum solubility into the ferrite matrix. The estimated Al2O3 particle strengthening stress is consistent with measured tensile stress at 973 K. Both stresses are slightly improved with increasing oxygen content, but are half the level of that in steel strengthened by Ce2O3 and CeAlO3 particles.

Similar content being viewed by others

References

K. Terrani, J. Nucl. Mater., 2014, vol. 448, pp. 420-435.

J.J. Powers, N.M. George, G.I. Maldonado, and A. Worrall: Report on Reactor Physics Assessment of Candidate Accident Tolerant Fuel Cladding Materials in LWRs, ORNL/TM-2015/415, Oak Ridge National Laboratory, 2015.

A. Kimura, R. Kasada, N. Iwata, H. Kishimoto, C.H. Zhang, J. Isselin, P. Dou, J.H. Lee, N. Muthukumar, T. Okuda, M. Inoue, S. Ohnuki, T. Fujisawa, and T.F. Abe, J Nucl. Mater., 2011, vol. 417, pp.176-179.

Y. Yano, T. Tanno, H. Oka, S. Ohtsuka, T. Inoue, S. Kato, T. Furukawa, T. Uwaba, T. Kaito, S. Ukai, N. Oono, A. Kimura, S. Hayashi, and T. Torimaru, J Nucl. Mater., 2017, vol. 487, pp. 229-237.

Y. Shizukawa, S. Ukai, N. Oono, S. Hayashi, S. Ohtsuka, T. Torimaru, and A. Kimura, Proc. on Advanced High-Temperature Materials Technology for Sustainable and Reliable Power Engineering (1213HiMST-2015) 29 June-3 July (2015) Sapporo, Japan.

S. Ukai, N. Oono, T. Kaito, T. Torimaru, A. Kimura, and S. Hayashi, in: The Ninth Pacific Rim International Conference on advanced Materials and Processing (PRICM9), The Japan Institute of Metals and Materials, 2016.

S. Ukai, N. Oono, K. Sakamoto, T. Tirimaru, T. Kaito, A. Kimura, and S. Hayashi, in Proc. of ICAPP 2017, Fukui and Kyoto (Japan), April 24–28 (2017).

H. Shibata, S. Ukai, N.H. Oono, K. Sakamoto, and M. Hirai, Jour. Nucl. Mater., 2018, vol. 502, pp. 228-235.

K. Shobu, Calphad, 2009, Vol. 33, pp. 279-287.

J. Ribis, and Y. de Carlan, Acta Materialia, 2012, vol. 60, pp. 238-252.

L. Ragnaesson, D. Sichen (2010) Process Metall. 1(1):40-47.

J. Ribis et al., Journal of nuclear Materials, 2013, vol. 442, pp. S101-S105

GR Odette (2018) Scripta Mater. 143:142-48.

L. Barnard et al., Acta Materialia, 2015, vol. 91, pp. 340-354.

C. Kenel et al., Intermetallics, 2017, vol. 90, pp. 63-73.

Sawada H., Mater Res Bull, 1994, vol. 29, pp. 127–133.

T. Ohashi, T. Hiromoto, H. Fujii, Y. Nuri, and K. Asanno, Tetsu-to-Hagane, 1976, No. 6.

B.L. Bramfitt, 1970, Metall. Trans. 1(1):1987-1995.

NIMS AtomWork Database: Y.S. Kim, Acta Cryst, 1968, pp. 295–29.

Naoko Oono, Q.X. Tang, and Shigeharu Ukai, Materials Science & Engineering A, 2016, vol. 649, pp. 250-253.

M. Palm (2009) Int. J. Mater. Res. 100 (3):277-287.

Y.C. Chuang, C.H. Wu, and Z.B. Shao, Journal of the Less Common Metals, 1987, vol. 136, pp.147-153.

R.O. Scattergood, and D.J. Bacon, Philosophical Magazine A, 1975, vol. 31, pp.179-198.

S. Ukai, T. Okuda, M. Fujiwara, T. Kobayashi, S. Mizuta, and H. Nakashima, J. Nucl. Sci. Technol., 2002, vol. 39, pp. 872-879.

Acknowledgments

This work is supported by Grant-in-Aid for Scientific Research (B), 16H04529, Japan Society for the Promotion of Science (JSPS). The authors would like to thank the laboratory of Nano-Micro Material-Analysis in Hokkaido University for the utilizing of XRD, FIB and TEM.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 16, 2018.

Rights and permissions

About this article

Cite this article

Shibata, H., Ukai, S., Oono, N.H. et al. Development of Accident-Tolerant FeCrAl Steels Containing Al2O3 Particles by Means of Internal Al Oxidation. Metall Mater Trans A 50, 1816–1824 (2019). https://doi.org/10.1007/s11661-019-05122-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05122-2