Abstract

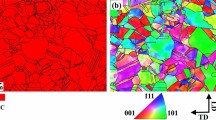

The precipitation of the η-Ni3(Ti, Al) phase at grain boundaries in austenitic stainless steels significantly affects grain-boundary-related properties of the bulk material. In this study, the precipitation behavior of the η-Ni3(Ti, Al) phase in a thermally aged austenitic precipitation-strengthened stainless steel was evaluated during aging at 750 °C for 0.5 to 64 hours using scanning electron microscopy, transmission electron microscopy, and atom probe tomography. A higher number of plate-like η-Ni3(Ti, Al) phase particles precipitated at the grain boundaries with increasing aging time, and grew into the grain interior until the entire grain was occupied by this phase. The η phase had a {0001}η//{111}γ, \( \langle 11\bar{2}0\rangle_{{{\upeta }}} \)//〈110〉γ semi-coherent orientation relationship with the matrix, and contained many stacking faults. Ni- and Ti-rich layers alternated periodically between adjacent stacking faults in the η phase. Al segregated at stacking faults and the interface between the η phase and matrix. The partition coefficients of Ni, Al, and Si between the η precipitates and matrix decreased with increased aging time; however, the partition coefficient of Ti did not change significantly. The partition coefficients of the other elements increased with increasing aging time. The Ti:Al ratio of the η phase significantly increased with increasing aging time. Based on the experimental results, the precipitation and growth behaviors of η-Ni3(Ti, Al) phase precipitated at grain boundaries were discussed, which are expected to contribute to the design of austenitic stainless steel compositions with improved mechanical properties.

Similar content being viewed by others

References

S.Q. Zhao, X.S. Xie, G.D. Smith, S.J. Patel: Mater. Sci. Eng., 2003, vol. 355A, pp. 96-105.

J.P. Shingledecker, G.M. Pharr: Metall. Mater. Trans., 2012, vol. A43, pp. 1902-10.

Z.H. Zhong, Y.F. Gu, Y. Yuan: Mater. Sci. Eng., 2015, vol. A622, pp. 101–7.

C.S. Wang, Y.A. Guo, J.T. Guo, L.Z. Zhou: Mater. Sci. Eng., 2015, vol. A639, pp. 380–8.

C.S. Wang, Y.A. Guo, J.T. Guo, L.Z. Zhou: Mater. Des., 2015, vol. 88, pp. 790–8.

T.T. Wang, C.S. Wang, W. Sun, X.Z. Qin, J.T. Guo, L.Z. Zhou: Mater. Des., 2014, vol. 62, pp. 225–32.

Y.L. Xu, L. Zhang, J. Li, X.S. Xiao, X.L. Cao, G.Q. Jia, Z. Shen: Mater. Sci. Eng., 2012, vol. 544A, pp. 48-53.

X.Z. Qin, J.T. Guo, C.Yuan, J.S. Hou, L.Z. Zhou, H.Q. Ye: Mater. Sci. Eng., 2012, vol. 543A, pp. 121-8.

J.A. Brooks, A.W. Thompson: Metall. Mater. Trans., 1993, vol. A24, pp. 1983-91.

H.D. Cicoo, M.I. Luppo, L.M. Gribaudo, J. Ovejero-Garcia: Mater. Character., 2004, vol. 52, pp. 85-92.

T.M. Smith, B.D. Esser, N. Antolin, G.B. Viswanathan, T. Hanlon, A. Wessman, D. Mourer, W. Windl, D.W. McComb, M.J. Mills: Acta Mater., 2015, vol. 100, pp. 19-31.

Y.U. Heo, M. Takeguchi, K. Furuya, H.C. Lee: Acta Mater., 2009, vol. 57, pp. 1176-87.

M. Detrois, R.C. Helmink, S. Tin: Metall. Mater. Trans., 2014, vol. A45, pp. 5332-43.

H. Leitner, M. Schober, R. Schnitzer: Acta Mater., 2010, vol. 58, pp. 1261-9.

S. Asgari, R. Sharghi-Moshtaghin, M. SadeghAhmadi, P. Pirouz: Phil. Mag., 2013, vol. 93, pp. 1351-70.

X.Y. Li, J. Zhang, L.J. Rong, Y.Y. Li: Chin. J. Mater. Res., 2006, vol. 20(2), pp. 113-9.

O.M. Messe, J.S. Barnard, E.J. Pickering, P.A. Midley, C.M.F. Rae: Phil. Mag., 2014, vol. 94, pp. 1132-52.

J.C. Zhao, V. Ravikumar, A.M. Beltran: Metall. Mater. Trans., 2001, vol. 32A, pp. 1271-82.

S. Antonov, M. Detrois, R.C. Helmink, S. Tin: J. Alloy Comp., 2015, vol. 626, pp. 76-86.

M.K. Miller, Atom probe tomography: analysis at the atomic level, 1st ed., Kluwer Academic / Plenum Publisher, New York, 1999, p.33.

J.M. Cairney, D.W. Saxey, D. McGrouther, S.P. Ringer: Phy. B, 2007, vol. 394, pp. 267-269.

H. Li, H. Song, W.Q. Liu, S. Xia, B.X. Zhou, C. Su, W.Y. Ding: Ultramicroscopy, 2015, vol. 159, pp. 255–264.

M. Schober, R. Schnitzer, H. Leitner: Ultramicroscopy, 2009, vol. 109, pp. 553–62.

M.J. Wong, P.G. Sanders, J.P. Shingledecker, C.L. White: Metall. Mater. Trans., 2015, vol. 46A, pp. 2947-55.

K. Hagihara, T. Nakano, Y. Umakoshi: Acta Mater., 2003, vol. 51, pp. 2623-37.

N.D. Evans, P.J. Maziasz, R.W. Swindeman, G.D. Smith:, Scr. Mater., 2004, vol. 51, pp. 503–7.

F. Long, Y.S. Yoo, C.Y. Jo, S.M. Seo, Y.S. Song, T. Jin, Z.Q. Hu: Mater. Sci. Eng., 2009, vol. 527A, pp. 361–9.

Acknowledgments

This work was supported by National Key Research Project and Development Program of China (No. 2016YFB0700401), Natural Science Foundation of China (No.51301103), and Special Fund for Instrument and Chemistry from Science and Technology Commission of Shanghai (No. 17142203100).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 27, 2018.

Rights and permissions

About this article

Cite this article

Li, H., Song, H. & Liu, W. Precipitation of η-Ni3(Ti, Al) Phase at Grain Boundaries in an Austenitic Precipitation-Strengthened Stainless Steel. Metall Mater Trans A 50, 915–923 (2019). https://doi.org/10.1007/s11661-018-5045-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-5045-x