Abstract

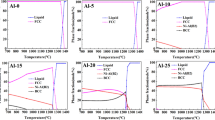

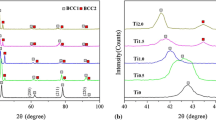

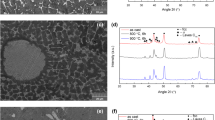

The thermodynamic parameters for a series of Fe(100−x)/2Co(100−x)/2Cux (x from 10 to 90, at. pct) alloys including their characteristic temperatures, the enthalpy and entropy changes of three phase transformations were determined systematically using differential scanning calorimetry (DSC). The corresponding vertical section of ternary Fe-Co-Cu phase diagram was predicted, and the relationships of the enthalpy and entropy changes vs Cu content were described by polynomial expressions. Metastable phase separation took place in those liquid Fe-Co-Cu alloys with the Cu content 30 ≤ x ≤ 70. The liquid phase separation temperatures were determined to outline the metastable miscibility gap, and the critical undercoolings to initiate phase separation were measured as a range of 57 K to 98 K. After such a phase separation, the liquid phase (to γ(Fe, Co)) exhibited the strongest undercooling ability in the Fe-Co-Cu alloys with x ≤ 70, whereas the solid-state undercooling for the eutectoid transformation is comparatively higher in the alloys with x > 70. The nanomechanical properties of α(Fe, Co) and (Cu) phases were measured by nanoindentation technique. In the Fe20Co20Cu60 alloy, both phases had the lowest nanohardness and reduced elastic modulus, and displayed severe creep behaviors, resulting mainly from its conspicuous liquid phase separation.

Similar content being viewed by others

References

D.L. Xie, L. Wan, D.D. Song, S. Wang, F. Lin, X.Y. Pan, and J. Xu, Mater. Design, 2015, vol. 87, pp. 482-87.

B. Bhoi, V. Srinivas, and V. Singh, J. Alloy. Compd., 2010, vol. 496, pp. 423-28.

A. Barbosa, G. Bobrovnitchii, A. Skury, R. Guimaraes, and M. Filgueira, Mater. Design, 2010, vol. 31, pp. 522-26.

S. Bein, C. Colinet, and M. Durand-Charre, J. Alloy. Compd., 2000, vol. 313, pp. 133-43.

M. Bamberger, A. Munitz, L. Kaufman, and R. Abbaschian, Calphad, 2002, vol. 26, pp. 375-84.

M. Palumbo, S. Curiotto, and L. Battezzati, Calphad, 2006, vol. 30, pp. 171–78.

W. Banda, G.A. Georgalli, C. Lang, and J.J. Eksteen, J. Alloy. Compd., 2008, vol. 461, pp. 178–82.

M.O. Ilatovskaya, R.V. Starykh, and S.I. Sinyova, Metall. Mater. Trans. B, 2015, vol. 46, pp. 243-49.

D.I. Kim, and R. Abbaschian, J. Phase Equilib., 2000, vol. 21, pp. 25–31.

M. Bamberger, A. Munitz, L. Kaufman, and R. Abbaschian, Calphad, 2002, vol. 26, pp. 375–84.

A. Munitz, A.M. Bamberger, S. Wannaparhun, and R. Abbaschian, J. Mater. Sci., 2006, vol. 41, pp. 2749–59.

F.P. Dai, and B. Wei, Chin. Sci. Bull., 2009, vol. 54, pp. 1287-94.

L. Zhao, and J.Z. Zhao, J. Mater. Res., 2013, vol. 28, pp. 1203-10.

Y.G. Yoo, W.T. Kim, S.C. Yu, and Y.D. Kim, J. Magn. Magn. Mater., 1996, vol. 157-158, pp. 233-34.

O. Crisan, J.M. Le Breton, A. Jianu, A. Maignan, M. Nogues, J. Teillet, and G. Filoti, J. Magn. Magn. Mater., 1999, vol. 196-197, pp. 467-69.

A. Sharifati and S. Sharafi, Mater. Design, 2012, vol. 41, pp. 8-15.

Y. Ruan and X.J. Wang, Phys. Status Solidi B, 2015, vol. 252, pp. 361-64.

U. Klancnik, J. Habjan, G. Klancnik, and J. Medved, J. Therm. Anal. Calorim, 2017, vol. 127, pp. 71-78.

T. Wang, T.E. Cullinan, and R.E. Napolitano, Acta Mater., 2014, vol. 62, pp. 188-96.

J. Orava, A.L. Greer, B. Gholipour, D.W. Hewak, and C.E. Smith, Nature Mater., 2012, vol. 11, pp. 279-83.

A. Deschamps, M. Garcia, J. Chevy, B. Davo, and F. De Geuser, Acta Mater., 2017, vol. 122, pp. 32-46.

I.R. Lu, M. Kolbe, G.P. Görler, and R. Willnecker, Mat. Sci. Eng. A, 2004, vol. 375-377, pp. 754-58.

I.S. Choi, M. Dao, and S. Suresh, J. Mech. Phys. Solids, 2008, vol. 56, pp. 157-71.

J.J. Kim, Y. Choi, S. Suresh, and A.S. Argon, Science, 2002, vol. 295, pp. 654-57.

H. Somekawa, and C.A. Schuh, Metall. Mater. Trans. A, 2016, vol. 47, pp. 3227-34.

V.V. Shastry, and U. Ramamurty, Acta Mater., 2013, vol. 61, pp. 5119-29.

D. Wu, J.S.C. Jang, and T.G. Nieh, Intermetallics, 2016, vol. 68, pp. 118-27.

Y. Ruan, A. Mohajerani, and M. Dao, Sci. Rep., 2016, vol. 6, pp. 31684.

Y. Ruan, Q.Q. Wang, S.Y. Chang, and B. Wei, Acta Mater., 2017, vol. 141, pp. 456-65.

W.C. Oliver and G.M. Pharr, J. Mater. Res., 2004, vol. 19, pp. 3-20.

C.D. Cao and G.P. Gorler, Chin. Phys. Lett., 2005, vol. 22, pp. 482-84.

W.R. Maddocks and G.E. Claussen: Special Report 14, 1936, p. 116.

P. Villars: ASM Alloy Phase Diagrams Database. ASM International, Materials Park, OH. http://www1.asminternational.org/AsmEnterprise/APD, 2006, Accessed 26 June 2013.

F.P. Dai, W.L. Wang, Y. Ruan, and B. Wei, Appl. Phys. A, 2018, vol. 124, pp. 20.

W.F. Gale and T.C. Totemeier: Smithells Metals Reference Book, 8th ed, Elsevier Butterworth-Heinemann, Butterworth, Oxford, 2004, p. 14.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (Grant Nos. U1660108, 51327901, and 51671161), China Scholarship Council and the Fundamental Research Funds for the Central Universities (Grant No. 3102018jgc009). The authors are thankful to Prof. M. Dao and Prof. S. Suresh in MIT for their constructive comments and support. The assistance of Mr. Q. Gao in the experimental work are also gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted June 5, 2018.

Rights and permissions

About this article

Cite this article

Ruan, Y., Dai, F.P., Chang, SY. et al. Thermodynamic Characteristics, Phase Separation, and Nanomechanical Properties of Ternary Fe-Co-Cu Alloys with Equiatomic Fe and Co Compositions. Metall Mater Trans A 49, 6255–6264 (2018). https://doi.org/10.1007/s11661-018-4944-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-4944-1