Abstract

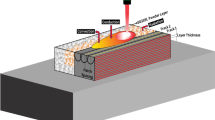

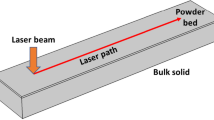

Solidification microstructure control via melt pool geometry control is investigated in detail for the AlSi10Mg alloy in a laser melting process. Relationships between cell spacing and melting process parameters—beam power and velocity, are investigated. Single beads and multi-layer pad experiments are performed and analyzed for melt pool geometry and microstructure. Information from these experiments is used to achieve location-specific control of cell spacing in a single part using an EOS laser powder bed fusion machine. Along with experiments, thermal modeling is used to map the effect of melting parameters on solidification conditions. Optical microscopy and scanning electron microscopy are used to determine the melt pool dimensions and cell spacing, respectively. Results from the model and experiments show that cell spacing can be varied by controlling the cooling rate of the melt pool via beam power and travel speed for both single bead and multi-layer pad experiments. In addition, the relationship between melt pool area and cooling rate is used to demonstrate integrated melt pool geometry and microstructure control. This is also critical for process qualification using simple observable metrics such as melt pool size. This relationship is then used to demonstrate location-specific control of cell spacing in a single component.

Similar content being viewed by others

References

EOS: Material Data Sheet. http://www.agile-manufacturing.com/files/materials/aluminum.pdf. Accessed 4 April 2016.

B. Fulcher, D. Leigh, and T. Watt: in Proceedings of Solid Freeform Fabrication Symposium, Austin, 2014, pp. 404–19.

N.T. Aboulkhair, I. Maskery, C. Tuck, I. Ashcroft, and N.M. Everitt: Mater. Sci. Eng. A, 2016, vol. 667, pp. 139–46.

M. Dantzig, J.A. Rappaz: Solidification, 1st edn, EPFL Press, London, 2009.

L. Lu, K. Nogita, S.D. McDonald, A.K. Dahle, L. Lu, and A.K. Dahle: JOM, 2004, vol. 56, pp. 52–8.

F. Grosselle, G. Timelli, F. Bonollo, and R. Molina: Metall. Sci. Technol., 2009, vol. 27, pp. 959–65.

K. Kempen, L. Thijs, J. Van Humbeeck, J.J.-P. Kruth, J. Van Humbeeck, and J.J.-P. Kruth: Phys. Procedia, 2012, vol. 39, pp. 439–46.

M. Tang, P.C. Pistorius, S. Narra, and J.L. Beuth: JOM, 2016, vol. 68, pp. 960–6.

F. Trevisan, F. Calignano, M. Lorusso, J. Pakkanen, A. Aversa, E. Ambrosio, M. Lombardi, P. Fino, and D. Manfredi: Materials (Basel)., 2017, vol. 10, p. 76.

B. AlMangour, D. Grzesiak, J. Cheng, and Y. Ertas: J. Mater. Process. Technol., 2018, vol. 257, pp. 288–301.

N. Raghavan, S. Simunovic, R. Dehoff, A. Plotkowski, J. Turner, M. Kirka, and S. Babu: Acta Mater., 2017, vol. 140, pp. 375–87.

S. Ghosh, L. Ma, N. Ofori-Opoku, and J.E. Guyer: Model. Simul. Mater. Sci. Eng. https://doi.org/10.1088/1361-651x/aa7369.

K. Kempen, L. Thijs, E. Yasa, M. Badrossamay, and J.-P. Kruth: in Solid Freeform Fabrication Symposium, Austin, 2011.

E. Brandl, U. Heckenberger, V. Holzinger, and D. Buchbinder: Mater. Des., 2012, vol. 34, pp. 159–69.

Q. Jia and D. Gu: J. Alloys Compd., 2014, vol. 585, pp. 713–21.

W. Gong, J. Qi, Z. Wang, Y. Chen, J. Jiang, Z. Wang, and Y. Qi: in 3rd International Symposium of Space Optical Instruments and Applications: Beijing, China June 26–29th 2016, Springer International Publishing, Berlin, 2017, pp. 113–20.

N.T.N. Aboulkhair, C. Tuck, I. Ashcroft, I. Maskery, and N.M. Everitt: Mater. Trans. A, 2015, vol. 46, pp. 3337–41.

H. Matyja, B.C. Giessen, and N.J. Grant: J. Inst. Met

J. Gockel: Ph.D. Thesis, Carnegie Mellon University, 2014.

E. Soylemez, J. Beuth, and K. Taminger: in Proceedings of 21st Solid Freeform Fabrication Symposium, 2010, pp. 571–82.

EOS M 290 - industrial 3D printed parts from metal materials. https://www.eos.info/eos-m290. Accessed 15 May 2017.

D. Dobranich and R.C. Dykhuizen: Scoping Thermal Calculation of the LENS Process, 1998.

S.A. Khairallah, A.T. Anderson, A. Rubenchik, and W.E. King: Acta Mater., 2016, vol. 108, pp. 36–45.

K.C. Mills: Recommended Values of Thermophysical Properties for Selected Commercial Alloys, Elsevier, 2002.

ASM Alloy Phase Diagram DatabaseTM - ASM International. http://www.asminternational.org/home/-/journal_content/56/10192/15469013/DATABASE. Accessed 2 March 2017.

J. Beuth and N. Klingbeil: JOM, 2001, vol. 53, pp. 36–9.

J. Beuth, J. Fox, J. Gockel, C. Montgomery, R. Yang, H. Qiao, E. Soylemes, P. Reeseewatt, A. Anvari, S. Narra, and N. Klingbeil: in Proceedings of Solid Freeform Fabrication Symposium, Austin, 2013, pp. 655–65.

Z. Francis: Ph.D. Thesis, Carnegie Mellon University, 2017.

ASTM Standard E112-13: Standard Test Methods for Determining Average Grain Size, West Conshohocken, Pennsylvania, 2013.

L.C. Wei, L.E. Ehrlich, M.J. Powell-Palm, C. Montgomery, J. Beuth, and J.A. Malen: Addit. Manuf., 2018, vol. 21, pp. 201–8.

S.P. Narra, R. Cunningham, J. Beuth, and A.D. Rollett: Addit. Manuf., 2018, vol. 19, pp. 160–6.

R. Cunningham, S.P. Narra, C. Montgomery, J. Beuth, and A.D. Rollett: JOM, 2017, vol. 69, pp. 479–84.

M. Tang, P.C. Pistorius, and J. Beuth: Addit. Manuf., 2017, vol. 14, pp. 39–48.

Acknowledgments

The authors wish to acknowledge Robert Speer, Martin Marinack, and John Siemon at the Arconic Technical Center for performing single bead experiments on their EOS M280 machine. The authors would like to thank Professor Anthony Rollett and Suraj Rao for providing particle size distribution information for AlSi10Mg powder. The authors would also like to convey their gratitude to William Pingitore for helping with sample preparation and Dr. Tom Nuhfer for helping with the SEM. This research was supported by the Research for Additive Manufacturing in Pennsylvania (RAMP) program, Prime Award Number FA8650-12-2-7230, Subaward Number 543105-78001, National Science Foundation under Award CMMI 1335298, and generous funding by a Carnegie Mellon Alumnus, Mr. Richard Fieler.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 31, 2018.

Rights and permissions

About this article

Cite this article

Narra, S.P., Scime, L. & Beuth, J. Integrated Control of Melt Pool Geometry and Microstructure in Laser Powder Bed Fusion of AlSi10Mg. Metall Mater Trans A 49, 5097–5106 (2018). https://doi.org/10.1007/s11661-018-4804-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-4804-z