Abstract

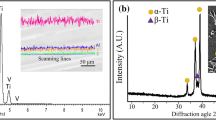

Application of the laser in machining has been demonstrated to improve the machinability in several metals and alloys. A very high heating and cooling rate during laser treatment tends to modify the microstructure significantly. In some materials, the change in the microstructural features affects the machinability of the materials. In this work, microstructure evolution due to laser treatment and its effect on the machinability of Ti6Al4V was studied using advanced characterization techniques. The microstructure of the surface and subsurface of the cylindrical Ti6Al4V rod was modified using a high-power laser source with varying laser scanning speeds. The laser treatment resulted in three distinctly different microstructures along the radial direction of the rod; these were classified as the lath dominant zone, a mixture of laths with equiaxed grains and equiaxed grains surrounded by bands. Rapid heating and cooling during laser scanning lead to the formation of the martensite phase and local strain development. Further, at the boundaries of laths, compressive twins (57 deg\( \left\langle {\bar{1}2\bar{1}0} \right\rangle \)) were formed because of laser heating. These twins are different from tensile twins (94.8 deg\( \left\langle {\bar{1}2\bar{1}0} \right\rangle \)), which are formed at the machined subsurface during deformation. The formation of a martensite phase and local strain development due to laser treatment resist the formation of localized shear bands along the thickness of machined chips during machining. This in turn also repels the crack propagation along the shear band developed during machining and enhances the machinability of the material.

Similar content being viewed by others

Notes

β phase was directly indexed by EBSD with more than 0.1 CI; it may be possible that all the fine β phase was not captured during the EBSD scan.

References

1 M. Ahmadi, Y. Karpat, O. Acar, and Y.E. Kalay: J. Mater. Process. Technol., 2018, vol. 252, pp. 333–47.

2 P.J. Arrazola, A. Garay, L.M. Iriarte, M. Armendia, S. Marya, and F. Le Maître: J. Mater. Process. Technol., 2009, vol. 209, pp. 2223–30.

I.S. Jawahir, E. Brinksmeier, R. M’Saoubi, D.K. Aspinwall, J.C. Outeiro, D. Meyer, D. Umbrello, and A. D. Jayal: CIRP Ann. Manuf. Technol., 2011, vol. 60, pp. 603–26.

4 M. Armendia, P. Osborne, A. Garay, J. Belloso, S. Turner, and P.J. Arrazola: Mater. Manuf. Process, 2012, vol. 27, pp. 457–61.

S. Joshi, P. Pawar, A. Tewari, and S.S. Joshi: CIRP Ann. Manuf. Technol., 2014, vol. 7, pp. 191–201.

6 P.J. Arrazola, T. Özel, D. Umbrello, M. Davies, and I.S. Jawahir: CIRP Ann. Manuf. Technol., 2013, vol. 62, pp. 695–718.

7 B. Vrancken, L. Thijs, J.P. Kruth, and J. Van Humbeeck: J. Alloys Compd., 2012, vol. 541, pp. 177–85.

8 W. Sha and S. Malinov: Titanium Alloys: Modelling of Microstructure, Properties and Applications, Woodhead Publishing Limited, 2009.

9 S.A. Abbasi, P. Feng, Y. Ma, J. Zhang, D. Yu, and Z. Wu: Int. J. Adv. Manuf. Technol., 2016, vol. 86, pp. 1393–1405.

10 Y. Ma, D. Yu, P. Feng, Z. Wu, and J. Zhang: Adv. Mech. Eng., 2015, vol. 7, pp. 1–10.

11 C.R. Dandekar, Y.C. Shin, and J. Barnes: Int. J. Mach. Tool. Manuf., 2010, vol. 50, pp. 174–82.

12 S. Joshi, A. Tewari, and S. Joshi: J. Manuf. Sci. Eng., 2014, vol. 135, pp. 1–11.

13 S. Sun, M. Brandt, and M.S. Dargusch: Int. J. Mach. Tool. Manuf., 2010, vol. 50, pp. 663–80.

14 V. Upadhyay, P.K. Jain, and N.K. Mehta: Adv. Mater. Res., 2012, vol. 622–623, pp. 361–65.

15 Y. Ayed, G. Germain, W. Ben Salem, and H. Hamdi: Finite Elem. Anal. Des., 2014, vol. 92, pp. 72–79.

16 M.J. Bermingham, W.M. Sim, D. Kent, S. Gardiner, and M.S. Dargusch: Wear, 2015, vol. 322–323, pp. 151–63.

17 F. Bridier, P. Villechaise, and J. Mendez: Acta Mater., 2005, vol. 53, pp. 555–67.

18 S. Sun, M. Brandt, and M.S. Dargusch: Metall. Mater. Trans. A, 2010, vol. 41A, pp. 1573–81.

R. A. R. Rashid, S. Sun, G. Wang, and M.S. Dargusch: Int. J. Mach. Tool. Manuf., 2012, vol. 63, pp. 58–69.

20 J. Yang, S. Sun, M. Brandt, and W. Yan: J. Mater. Process. Technol., 2010, vol. 210, pp. 2215–22.

21 Y. Jeon and C.M. Lee: Int. J. Precis. Eng. Man., 2012, vol. 13, pp. 311–17.

22 S.I. Wright, M.M. Nowell, S.P. Lindeman, P.P. Camus, M. De Graef, and M.A. Jackson: Ultramicroscopy, 2015, vol. 159, pp. 81–94.

23 S. Balachandran, A. Kashiwar, A. Choudhury, D. Banerjee, R. Shi, and Y. Wang: Acta Mater., 2016, vol. 106, pp. 374–87.

24 A.M. Kamat, S.M. Copley, and J.A. Todd: Surf. Coat. Technol., 2017, vol. 313, pp. 82–95.

25 C. Liu, L. Yu, A. Zhang, X. Tian, D. Liu, and S. Ma: Mater. Sci. Eng. A, 2016, vol. 673, pp. 185–92.

26 Z. Li, J. Li, J. Liu, D. Liu, and H. Wang: J. Alloys Compd., 2016, vol. 657, pp. 278–85.

27 H. Li, Z. Ji, and H. Yang: Mater. Charact., 2013, vol. 76, pp. 6–20.

28 S.I. Wright, M.M. Nowell, R. De Kloe, P. Camus, and T. Rampton: Ultramicroscopy, 2015, vol. 148, pp. 132–45.

29 W. Pfleging, R. Kumari, H. Besser, T. Scharnweber, and J. Dutta: Appl. Surf. Sci., 2015, vol. 355, pp. 104–11.

30 J. Xu, W. Zeng, Y. Zhao, X. Sun, and Z. Du: J. Alloys Compd., 2016, vol. 688, pp. 301–09.

31 A. Bhattacharjee, V.K. Varma, S. V Kamat, A.K. Gogia, and S. Bhargava: Metall. Mater. Trans. A, 2006, vol. 37A, p. 1423 – 33.

32 Y. Ohmori, T. Ogo, K. Nakai, and S. Kobayashi: Mater. Sci. Eng. A, 2001, vol. 312, pp. 182–88.

33 M. Niewczas: Acta Mater., 2010, vol. 58, pp. 5848–57.

34 L. Yang, S. Li, X. Chang, H. Zhong, and H. Fu: Acta Mater., 2015, vol. 97, pp. 269–81.

35 J. Lind, S.F. Li, R. Pokharel, U. Lienert, A.D. Rollett, and R.M. Suter: Acta Mater., 2014, vol. 76, pp. 213–20.

36 S. Sun, M. Brandt, and M.S. Dargusch: Int. J. Mach. Tool. Manuf., 2009, vol. 49, pp. 561–68.

37 B. Wang and Z. Liu: Mater. Des., 2016, vol. 98, pp. 68–78.

38 J. Peirs, W. Tirry, B. Amin-Ahmadi, F. Coghe, P. Verleysen, L. Rabet, D. Schryvers, and J. Degrieck: Mater. Charact., 2013, vol. 75, pp. 79–92.

39 S. Zhang, J. Zhou, L. Wang, H. Liu, and S. Dong: Mater. Sci. Eng. A, 2015, vol. 632, pp. 78–81.

Acknowledgments

The authors gratefully acknowledge Machine Tool Lab (Mechanical Engineering Department), the National Facility of Texture and [OIM–a DST-IPHRA] (Metallurgical Engineering and Materials Science Department) and Sophisticated Analytical Instrument Facility (SAIF) at IIT Bombay for providing experimental facilities. The authors also acknowledge the Raja Ramanna Centre for Advanced Technology (RRCAT), Indore, India, for providing the experimental facilities for laser treatment. Further, the authors acknowledge the National Center for Aerospace Innovation (NCAIR) and Research for providing the funding for this project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manscript submitted January 3, 2018.

Rights and permissions

About this article

Cite this article

Telrandhe, S.V., Jayabalan, B., Paul, C.P. et al. Microstructural Development Due to Laser Treatment and Its Effect on Machinability of Ti6Al4V Alloy. Metall Mater Trans A 49, 3450–3467 (2018). https://doi.org/10.1007/s11661-018-4728-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-4728-7