Abstract

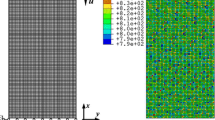

The relationship among processing, microstructure, and mechanical performance is the most important for metallic glass matrix composites (MGCs). Numerical modeling was performed on the shear banding in MGCs, and the impacts of particle concentration, morphology, agglomerate, size, and thermal residual stress were revealed. Based on the shear damage criterion, the equivalent plastic strain acted as an internal state variable to depict the nucleation, growth, and coalescence of shear bands. The element deletion technique was employed to describe the process of transformation from shear band to micro-crack. The impedance effect of particle morphology on the propagation of shear bands was discussed, whereby the toughening mechanism was clearly interpreted. The present work contributes to the subsequent strengthening and toughening design of MGCs.

Similar content being viewed by others

References

J.W. Qiao, H.L. Jia, and P.K. Liaw: Mater. Sci. Eng. R., 2016, vol. 100, pp. 1–69.

J.S.C. Jang, T.H. Li, P.H. Tsai, J.C. Huang, and T.G. Nieh: Intermetallics, 2015, vol. 64, pp. 102–05.

J.B. Li, J.S.C. Jang, S.R. Jian, K.W. Chen, J.F. Lin, and J.C. Huang: Mater. Sci. Eng. A., 2001, vol. 528, pp. 8244–8.

X.H. Du, J.C. Huang, H.M. Chen, H.S. Chou, Y.H. Lai, K.C. Hsieh, J.S.C. Jang, and P.K. Liaw: Intermetallics, 2009, vol. 17, pp. 607–13.

H.M. Chen, X.H. Du, J.C. Huang, J.S.C. Jang, and T.G. Nieh: Intermetallics, 2009, vol. 17, pp. 330–5.

P.J. Hsieh, L.C. Yang, H.C. Su, C.C. Lu, and J.S.C. Jang: J. Alloy Compd., 2010, vol. 504, pp. 98–101.

M.E. Siegrist, and J. F. Löffler: Scripta Mater., 2007, vol. 56, pp. 1079–82.

J.L. Wu, Y. Pan, X.Z. Li, and X.F. Wang: Mater. Design, 2015, vol. 75, pp. 32–9.

D.K. Balch, E. Üstündag, and D.C. Dunand: J. Non-Cryst. Solids, 2003, vol. 317, pp. 176–80.

C.N. Kuo, J.C. Huang, X.H. Du, X.J. Liu, and T.G. Nieh: J. Alloy Compd., 2014, vol. 586, pp. S14–9.

X.D. Wang, R.T. Qu, Z.Q. Liu, and Z.F. Zhang: J. Alloy Compd., 2017, vol. 695, pp. 2016–22.

Y.P. Jiang, and K. Qiu: Mater. Design, 2015, vol. 65, pp. 410–6.

Y.P. Jiang, X.P. Shi, and K. Qiu: Mater. Design, 2015, vol. 77, pp. 32–40.

S.B. Biner: Acta Mater., 2006, vol. 54, pp. 139–50.

E.R. Homer, and C.A. Schuh: Acta Mater., 2009, vol. 57, pp. 2823–33.

H.Y. Zhang, and G.P. Zheng: J. Alloy Compd., 2014, vol. 586, pp. S262–6.

M. Bansal, I.V. Singh, B.K. Mishra, K. Sharma, and I.A. Khan: J. Nucl. Mater., 2017, vol. 487, pp. 143-57.

ABAQUS theory manual (HKS inc., 2010), pp. 510.

H. Hooputra, H, Gese, H. Dell, and H. Werner: Int. J. Crashworthiness, 2004, vol. 9, pp. 449–64.

Y.P. Jiang, L.G. Sun, Q.Q. Wu, and K. Qiu: J. Non-Cryst. Solids, 2017, vol. 459, pp. 26–31.

H.L. Ma, G.K. Hu, and Z.P. Huang: Mech. Mater., 2004, vol. 36, pp. 359–68.

B. Sarac, J. Wilmers, and S. Bargmann: Mater. Lett., 2014, vol. 134, pp. 306–10.

F. Abdeljawad, and M. Haataja: Phys. Rev. Lett., 2010, vol. 105, pp. 125503.

P.J. Hsieh, L.C. Yang, H.C. Su, C.C. Lu, and J.S.C. Jang: J. Alloy Compd., 2010, vol. 504, pp. 98–101.

J.S.C. Jang, J.Y. Cou, T.H. Li, J.C. Huang, and T.G. Nieh: Intermetallics, 2010, vol. 18, pp. 451–8.

J.S.C. Jang, J.B. Li, S.L. Lee, Y.S. Chang, S.R. Jian, J.C. Huang, and T.G. Nieh: Intermetallics, 2012, vol. 30, pp. 25–9.

Y. Wu, H. Wang, H.H. Wu, Z.Y. Zhang, X.D. Hui, G.L. Chen, D. Ma, X.L. Wang, and Z.P. Lu: Acta Mater., 2011, vol. 59, pp. 2928–36.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted June 7, 2017.

Rights and permissions

About this article

Cite this article

Jiang, Y., Qiu, K., Sun, L. et al. Modeling of Metallic Glass Matrix Composites Under Compression: Microstructure Effect on Shear Band Evolution. Metall Mater Trans A 49, 417–424 (2018). https://doi.org/10.1007/s11661-017-4412-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-017-4412-3