Abstract

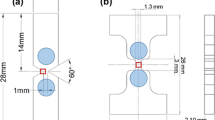

Defect frequency, a fatigue crack prognostics indicator, is defined as the number of microcracks per second detected using a laser beam that is scanned across a surface at a constant predetermined frequency. In the present article, a mechanistic approach was taken to develop a methodology for deducing crack length and crack growth information from defect frequency data generated from laser scanning measurements made on fatigued surfaces. The method was developed by considering a defect frequency vs fatigue cycle curve that comprised three regions: (i) a crack initiation regime of rising defect frequency, (ii) a plateau region of a relatively constant defect frequency, and (iii) a region of rapid rising defect frequency due to crack growth. Relations between defect frequency and fatigue cycle were developed for each of these three regions and utilized to deduce crack depth information from laser scanning data of 7075-T6 notched specimens. The proposed method was validated using experimental data of crack density and crack length data from the literature for a structural steel. The proposed approach was successful in predicting the length or depth of small fatigue cracks in notched 7075-T6 specimens and in smooth fatigue specimens of a structural steel.

Similar content being viewed by others

References

J.N. Kudva, M.J. Grage, and M.M. Roberts: Proc. of the 2nd Int. Workshop Struct. Health Monit., Stanford University, Palo Alto, 1999, pp. 106–19.

C. Boller, Smart Materials and Structures, Vol. 10, No. 3, 2001, pp. 432–40.

E. Burke, N. Ashbaugh, S. Sathish, S. Freed, and A. Rosenberger: in Materials Damage Prognosis, J.M. Larsen, eds., TMS (The Minerals, Metals & Materials Society), 2005, pp. 217–21.

M. Karuskevich, O. Karuskevich, T. Maslak, and S. Schepak, International Journal of Fatigue, Vol. 39, 2012, pp. 116–21.

M. Petrasek, S. Ignatovich, M. Karuskevich, and T. Maslak, Advances in Military Technology, Vol. 8, No. 2, December 2013, pp. 84–91.

P. O. Maruschak, I. V. Konovalenko, T. Vuherer, S. V. Panin, F. Berto, I. M. Danyliuk, and A. Menou, Procedia Structural Integrity, Vol. 2, 2016, pp. 1928–35.

J. Buerkle, D. Dunn-Rankin, K. Bowo, and J.C. Earthman, Mater. Eval., 1992, vol. 50, pp. 670–77.

P. A. Schmidt and J. C. Earthman, J. Mater. Res., Vol. 10, 1995, pp. 372–380.

K. J. C. Chou and J. C. Earthman, J. Materials Research, Vol. 12, No. 8, 1997, pp. 2048–56.

B.D. Buckner, V. Markov, and J.C. Earthman: IEEE Sensors, 2005, p. 4.

B. D. Buckner, V. B. Markov, L.-C. Lai, and J. C. Earthman, Opt. Eng,. Vol. 47, No. 5, 2008, p. 054402.

L. I. Muravsky, P. Picart, A.B. Kmet, T. I. Voronyak, O. P. Ostash, and I. V. Stasyshyn: Optical Engineering, Vol 55, No. 10, 2016, 104108.

C. Laird: in Fatigue and Microstructure, M. Meshii, eds., ASM, Metals Park, 1979, pp. 149–203.

J. Man, K. Obrtlik, and J. Polák, Philosophical Magazine, Vol. 89, No. 16, 2009, pp. 1295–1336.

J. Man, P. Klapetek, O. Man, A. Weidner, K. Obrtlik, and J. Polák, Philosophical Magazine, Vol. 89, No. 16, 2009, pp. 1337–72.

P. Lukáš and L. Kunz, Materials Science and Engineering A, Vol. 314, 2001, pp. 75–80.

J. Polák, J. Man, T. Vystavěl, and M. Petrenec, Materials Science and Engineering A, Vol. 517, 2009, pp. 204–11.

K. Tanaka and T. Mura, Metall. Trans., Vol. 13A, 1982, pp. 117–123.

K. S. Chan, Metall. Mater. Trans. A, Vol. 34A, 2003, pp. 43–58.

K. S. Chan, Int. J. of Fatigue, Vol. 32, 2010, pp. 142–47.

C. Déprés, C. F. Robertson, and M. C. Fivel, Materials Science and Engineering A, Vols. 387-389, 2004, pp. 288–91.

T. Savas and J. C. Earthman, Journal of Materials Engineering and Performance, Vol. 23, 2014, pp. 2131–38.

V. Markov, B.D. Bucker, J. Angeles, and J.C. Earthman: in Materials Damage Prognosis, J.M. Larson eds., Proceedings of the Materials Damage Prognosis Symposium, Materials Science & Technology 2004 Conference, TMS, 2005, pp. 229–35.

K. S. Chan, J. W. Tian, B. Yang, and P. K. Liaw, Metall. Mater. Transactions A, Vol. 40A, 2009, pp. 2545–56.

J. Lankford and D.L. Davidson: in Small Fatigue Cracks, R.O. Ritchie and J. Lankford, eds., The Metallurgical Society, Warrendale, 1986, pp. 51–71.

Y. Hong, L. Zheng, and Y. Qiao, Fat. Fract. Engng. Mater. Struct., Vol. 25, 2002, pp. 459–66.

Acknowledgments

This material is based upon work supported by the contractors under Contract No. W31P4Q-09-C-0258 with MetroLaser Inc. (Irvine, CA) and through Subcontract SwRI02AM09 with SwRI and a subcontract with UC-Irvine. The views, opinions, and/or findings expressed are those of the author(s) and should not be interpreted as representing the official views or policies of the Department of Defense or the U.S. Government.

Author information

Authors and Affiliations

Corresponding author

Additional information

Distribution A. Approved for public release: distribution unlimited.

Manuscript submitted June 12, 2017.

Rights and permissions

About this article

Cite this article

Chan, K.S., Buckner, B.D. & Earthman, J.C. Fatigue Crack Prognostics by Optical Quantification of Defect Frequency. Metall Mater Trans A 49, 117–127 (2018). https://doi.org/10.1007/s11661-017-4393-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-017-4393-2