Abstract

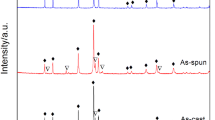

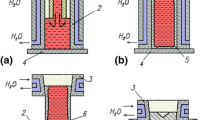

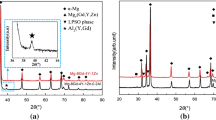

It has been well documented that recovery occurring in metals/alloys produced via solid-state quenching involves only annihilation of supersaturated vacancies. Interestingly, in the present study, we observed completely different mechanisms underlying recovery during annealing of an Al-Zn-Mg-Cu (7075 Al) alloy processed via liquid-state quenching, i.e., rapid solidification (specifically melt spinning herein). The as-melt-spun alloy consists of refined grains containing tangled dislocations inside the grains. Following annealing at 393 K (120 °C) for 24 hours, refined grain structure was still retained and grain sizes essentially remained unchanged, but subgrains separated by dense dislocation walls were generated at grain interiors, with a much lower density of dislocations at subgrain interiors than that in the as-melt-spun 7075 Al alloy and dislocation arrays inside some subgrains. The microstructural evolution suggests the absence of recrystallization and the occurrence of recovery primarily via the annihilation and rearrangement of dislocations and the formation of subgrains. Based on the stored energy in dislocations in, and the annealing temperature of, the as-melt-spun 7075 Al alloy, the recovery phenomenon was analyzed and discussed in detail.

Similar content being viewed by others

References

R.D. Doherty, D.A. Hughes, F.J. Humphreys, J.J. Jonas, D.J. Jensen, M.E. Kassner, W.E. King, T.R. McNelley, H.J. McQueen, and A.D.Rollett: Mater. Sci. Eng. A, 1997, vol. 238, pp. 219–74.

D. Raabe: Recovery and recrystallization: phenomena, physics, models, and simulation, in: Physical Metallurgy, 5th ed., D.E. Laughlin and K. Hono, eds., The Book Depository US, London, UK, 2014.

F.J. Humphreys and M. Hatherly: Recrystallization and Related Annealing Phenomena, 2nd ed., Elsevier, Boston, MA, 2004.

A.K. Sinha: Physical Metallurgy Handbook, McGraw-Hill Education, New York, 2002.

J. Wyrill: The Theory of Transformations in Metals and Alloys, Elsevier Science & Technolog, London, UK, 1965.

F. Prinz, A.S. Argon, and W.C. Moffatt: Acta Metall., 1982, vol. 30, pp. 821–30.

A. Rueanngoen, M. Imai, K. Yoshida, and T. Yano: J. Nucl. Mater., 2013, vol. 437, pp. 235–39.

L.M. Voronova, M.V. Degtyarev, T.I. Chashchukhina, Yu.G. Krasnoperova, and N.N. Resnina: Mater. Sci. Eng. A., 2015, vol. 639, pp. 155–64.

S. Yamazaki, K. Yoshida, and T. Yano: J. Nucl. Mater., 2011, vol. 417, pp. 425–29.

T. Yano, Y. Youb, and K. Kanazawa: J. Nucl. Mater., 2014, vol. 455, pp. 445–49.

J. Drouet, L. Dupuy, F. Onimus, and F. Mompiou: Scr. Mater., 2016, vol. 119, pp. 71–75.

L. Balogh, D.W. Brown, P. Mosbrucker, F. Long, and M.R. Daymond: Acta Mater., 2012, vol. 60, pp. 5567–77.

R.S. Wang, C.L. Xu, X.B. Liu, P. Huang, and A. Ren: J. Alloy Compd., 2013, vol. 581, pp. 788–92.

T. Yano, Y. Futamura, and S. Yamazaki: J. Nucl. Mater., 2013, vol. 442, pp. S399–S403.

K.D. Rasch, R.W. Siegel, and H. Schultz: J. Nucl. Mater., 1978, vol. 69 & 70, pp. 622–24.

K.D. Rasch, R.W. Siegel, and H. Schultz: Philos. Mag. A, 1980, vol. 41, pp. 91-117.

H.P. Klug and L. Alexander: X-ray Diffraction Procedures for Polycrystalline and Amorphous Materials, 2nd ed., John Wiley and Sons, New York, 1974.

G.K. Williamson and R.E. Smallman: Philos. Mag., 1956, vol. 1, pp. 34–46.

J.R. Davis: Aluminum and Aluminum Alloys, ASM International, Materials Park, OH, 1993.

D.A. Porter, K.E. Easterling, and M.Y. Sherif: Phase Transformations in Metals and Alloys, CRC Press, Boca Raton, FL, 2009.

Y.J. Lin, B. Wu, S.L. Li, S.Y. Mao, X.J. Liu, Y.Q. Zhang, and L.M. Wang: Mater. Sci. Eng. A, 2015, vol. 621, pp. 212-17.

O. Engler and V. Randle: Introduction to Texture Analysis: Macrotexture, Microtexture and Orientation Mapping, Taylor and Francis Group, Boca Raton, FL, 2010.

Acknowledgments

Y.J. Lin acknowledges the financial support from the Fundamental Research Funds for the Central Universities (Grant No. WUT: 2016IVA003) and the One-Hundred Talents Project (Project No. 2010100005), Hebei, China. L.M. Wang acknowledges the financial support provided by the National Basic Research Program of China (973 Program No. 2015CB856805); National Natural Science Foundation of China (NSFC) (Grant No. 51421091).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted 25 June, 2016.

Rights and permissions

About this article

Cite this article

Yan, Z., Mao, S., Lin, Y. et al. Recovery Phenomenon During Annealing of an As-Rapidly Solidified Al Alloy. Metall Mater Trans A 48, 3027–3035 (2017). https://doi.org/10.1007/s11661-017-4049-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-017-4049-2