Abstract

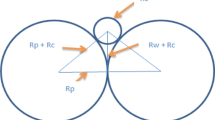

Lotus-type porous aluminums with porosities from 10 to 26 pct were fabricated with the Bridgman-type directional solidification method (Gasar). A vacuum atmosphere is critical to obtain high-porosity lotus-type porous aluminum by the Gasar process. The lotus-type porous aluminum was directionally solidified under a pure hydrogen pressure of 0.2 to 16 kPa. The influence of hydrogen pressure on the porosity and pore size in vacuum was investigated. The porosity and pore size increase with decreasing hydrogen pressure, but there exists a maximum porosity at some critical hydrogen pressure. Since a low hydrogen pressure is adopted, the effect of capillary pressure and hydrostatic pressure on the porosity becomes important. With the decreasing of hydrogen pressure, the influence of hydrostatic pressure and capillary pressure on porosity becomes stronger and stronger. The influence of melt height, which is proportional hydrostatic pressure, on porosity and pore size was investigated. The calculated porosities considering capillary pressure and hydrostatic pressure are in good agreement with experimental results.

Similar content being viewed by others

References

[1]. V. Shapovalov: MRS Bull., 1994, vol. 19, pp. 24–28.

[2]. V. Shapovalov and L.Boyko: Adv. Eng. Mater., 2004, vol. 6, pp. 407-10

[3]. S.K. Hyun, K. Murakami, and H. Nakajima: Mater. Sci. Eng., A, 2001, vol.299, pp. 241-48.

[4].Y. Liu, Y. Li, J. Wan, and H. Zhang: Metall. Mater. Trans. A, 2006. vol. 37A, pp. 2871–78.

[5]. L. Drenchev, J. Sobczak, S. Malinov, and W. Sha: Mater. Sci.Technol., 2006, vol. 22, pp. 1135-47.

[6]. L. Drenchev, J. Sobczak, W. Sha and S. Malinov: J. Mater. Sci., 2005, vol.40, pp.2525-29.

[7]. H. Zhang, Y. Li, and Y. Liu: Acta Metall. Sin., 2007, vol. 43, pp. 113–18.

[8]. H. Zhang, Y. Li, and Y. Liu: Acta Metall. Sin., 2007, vol. 43, pp. 11–16.

[9]. J.S. Park, S.K. Hyun, S. Suzuki, and H. Nakajima: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 406–14.

[10]. S. Suzuki, T. B. Kim, and H. Nakajima: J. Phys: Conf. Ser., 2009, vol.165, p. 012068.

[11]. T. B. Kim, M. Tane, S. Suzuki, and H. Nakajima: Mater. Trans, 2010, vol. 51, pp. 1871-77.

[12]. T. B. Kim, S. Suzuki, and H. Nakajima: Mater Trans, 2010, vol. 51, pp. 496-502.

[13]. T. Ide, Y. Iio, and H. Nakajima: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 5140-52.

[14]. J.S. Park, S.K. Hyun, S. Suzuki, and H. Nakajima: Acta Mater., 2007, vol. 55, pp. 5646–54.

[15]. H. Nakajima, and T. Ide: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 390-94.

[16]. S.Y. Kim, J.S. Park, and H. Nakajima: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 937-42.

[17]. J.S. Park, and H. Nakajima: J. Phys: Conf. Ser., 2009, vol.165, p. 012066.

[18]. D. E. J. Talbot, and P. N. Anyalebechi: Mater. Sci. Technol., 1988, vol.4, pp. 1-4.

[19]. B.J. Keene: Int. Mater. Rev., 1993, vol. 38(4), pp. 157-92.

[20]. J.P. Anson, R.A.L. Drew and J.E. Gruzleski: Metall. Mater. Trans. B, 1999, vol. 30B, pp. 1027-32.

[21]. G.S. Vinod Kumar, M. Mukherjee, F. Garcia-Moreno, and J. Banhart: Metall. Mater. Trans. A, 2013, vol. 44A, pp. 419-26.

[22]. H. Zhang, Y. Li, and Y. Liu: Acta Metall. Sin., 2006, vol. 42, pp. 1171–76.

Acknowledgments

This work was financially supported by National Natural Science Foundations No. 51371104, International Science and Technology Cooperation Program of China No. 2013DFR50330.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 2, 2016.

Rights and permissions

About this article

Cite this article

Liu, X., Li, Y. & He, Y. Fabrication of High-Porosity Lotus-Type Porous Aluminum in Vacuum. Metall Mater Trans A 48, 1264–1272 (2017). https://doi.org/10.1007/s11661-016-3930-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3930-8