Abstract

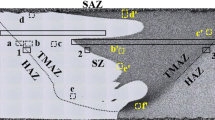

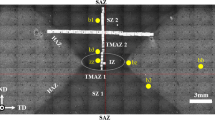

The evolution of microstructure and crystallographic texture has been investigated in double-sided friction stir welded microalloyed steel, using electron backscatter diffraction (EBSD). The microstructure analyses show that the center of stirred zone reached a temperature between Ac1 and Ac3 during FSW, resulting in a dual-phase austenitic/ ferritic microstructure. The temperatures in the thermo-mechanically affected zone and the overlapped area between the first and second weld pass did not exceed the Ac1. The shear generated by the rotation probe occurs in austenitic/ferritic phase field where the austenite portion of the microstructure is transformed to a bainitic ferrite, on cooling. Analysis of crystallographic textures with regard to shear flow lines generated by the probe tool shows the dominance of simple shear components across the whole weld. The austenite texture at Ac1 - Ac3 is dominated by the B\( \left\{ {1\bar{1}2} \right\}\langle 110\rangle \) and \( \bar{B} \) \( \left\{ {\bar{1}1\bar{2}} \right\}\langle \bar{1}\bar{1}0\rangle \) simple shear texture components, where the bainite phase textures formed on cooling were inherited from the shear textures of the austenite phase with relatively strong variant selection. The ferrite portion of the stirred zone and the ferrites in the thermo-mechanically affected zones and the overlapped area underwent shear deformation with textures dominated by the D1 \( \left\{ {\bar{1}\bar{1}2} \right\}\langle 111\rangle \) and D2 \( \left\{ {11\bar{2}} \right\}\langle 111\rangle \) simple shear texture components. The formation of ultrafine equiaxed ferrite with submicron grain size has been observed in the overlapped area between the first and second weld pass. This is due to continuous dynamic strain-induced recrystallization as a result of simultaneous severe shear deformation and drastic undercooling.

Similar content being viewed by others

References

W.M. Thomas, E.D. Nicholas, J.C. Needham, M.G. Murch, P. Temple-Smith, C.J. Dawes: International Patent application no. PCT/GB92/02203 and GB Patent application No. 9125978·8 and US Patent application no. 5,460,317, 1991.

2. W.M. Thomas, C.J. Dawes, Weld 1996, vol. 75, pp. 41 - 45.

3. G. Cam, Int. Mater. Rev. 2011, vol. 56, pp. 1 - 48.

4. J.M. Root, D.P. Field, T.W. Nelson, Metall. Mater. Trans. A 2009, vol. 40, pp. 2109-2014.

5. Y. S. Sato, T. W. Nelson, C. J. Sterling, Acta Mater. 2005, vol. 53, pp. 637 - 645.

6. S. Mironov, Y. S. Sato, H. Kokawa, H. Inoue, S.Tsuge Acta Mater. 2011, vol. 59, pp. 5472-5481.

7. T. J. Lienert, W. L. Stellwag, B. B. Grimmett, R. W. Warke, Supplement Weld. J 2003, vol. 82, pp. 1s - 9s.

8. M. Gosh, K. Kumar, R. S. Mishra, Scripta Mater. 2010, vol. 63, pp. 851 - 854.

9. J. Young, D. P. Field, T. W. Nelson, Metall. Mater. Trans. A 2013, vol. 44, pp. 3167 - 3172.

10. M. Jafarzadegan, A. Abdollah-zadeh, A. H. Feng, T. Saeid, J. Shen, H. Assadi, J. Mater. Sci. Technol. 2013, vol. 29, pp. 367 - 372.

11. S. J. Barnes, A. Steuwer, S. Mahawish, R. Johnson, P. J. Withers, Mater. Sci. Eng., A 2008, vol. 492, pp. 35 - 44.

12. P.J. Konol, J.A. Mathers, R. Johnson, J.R. Pickens, J. Ship Prod. 2003, vol. 19, pp. 159 - 164.

N.A. McPherson, A.M. Galloway, S.R. Cater, and M.M. Osman: In 19th Int.Conf. Trends in Welding Research, (2013), pp. 284–290.

G.P. Mercier and M. Reik: Concurrent Technologies Corporation 2000.

15. P. A. Manohar, M. Ferry, T. Chandra, ISIJ Int. 1998, vol. 38, pp. 913 - 924.

16. S. F. Medina, A. Quispe, M. Gomez, Mater. Sci. Forum 2012, vol. 706, pp. 2176-2180.

17. S. Vervynckt, K. Verbeken, B. Lopez, J. J. Jonas, Int. Mater. Rev. 2012, vol. 57, pp. 187 - 207.

T.N. Baker and N.A. McPherson: Mater. Sci. Technol. 2016 (in press).

19. P. L. Threadgill, Sci. Technol. Weld. Joining 2007, vol. 12, pp. 357 - 360.

20. A. Toumpis, A. Galloway, S. Cater, N. McPherson, Mater. Des. 2014, vol. 62, pp. 64-75.

21. S. Mironov, Y. S. Sato, H. Kokawa, Acta Mater. 2008, vol. 56, pp. 2602-2614.

22. H. H. Cho, H. N. Han, S. T. Hong, J. H. Park, Y. J. Kwon, S. H. Kim, R. J. Steel, Mater. Sci. Eng., A 2011, vol. 528, pp. 2889-2894.

D. P. Field, T. W. Nelson, Y. Hovanski, K. V. Jata, Metall. Mater. Trans. A 2001, vol. 32, pp. 2869-2877.

Y. S. Sato, H. Kokawa, K. Ikeda, M. Enomoto, S. Jogan, T. Hashimoto, Metall. Mater. Trans. A 2001, vol. 32, pp. 941–948.

25. M. M. Z. Ahmed, B. P. Wynne, W. M. Rainforth, P. L. Threadgill, Scripta Mater. 2008, vol. 59, pp. 507 - 510.

B.D. Nelson: Using Design of Experiments and Electron Backscatter Diffraction to Model Extended Plasticity Mechanisms in Friction Stir Welded AISI 304L Stainless Steel (Brigham Young University, 2010). All Theses and Dissertations. Paper 2582.

27. H. H. Cho, S. H. Kang, S. H. Kim, K. H. Oh, H. J. Kim, W. S. Chang, H. N. Han, Mater. Des. 2012, vol. 34, pp. 258-267.

28. P. Baillie, S. W. Campbell, A. M. Galloway, S. R. Cater, N. A. McPherson, International Journal of Chemical, Nuclear, Metallurgical and Materials Engineering 2014, vol. 8, pp. 651 - 655.

M.E. Fitzpatrick, A.T. Fry, P. Holdway, F.A. Kandil, J. Shackleton and L. Suominen: NPL Measurement Good Practice Guide No. 52, 2005.

30. D. Raabe, K. Lüucke, Mater. Sci. Technol. 1993, vol. 9, p. 302.

31. M. Ghosh, K. Kumar, R. S. Mishra, Mater. Sci. Eng., A 2011, vol. 528, pp. 8111-8119.

32. M. Matsushita, Y. Kitani, R. Ikeda, M. Ono, H. Fuji, Y. D. Chung, Sci. Technol. Weld. Joining 2011, vol. 16, pp. 181-187.

33. L. Gavard, H. K. D. H. Bhadeshia, D. J. C. Mackay, S. Suzuki, Mater. Sci. Technol. 1996, vol. 12, pp. 453-463.

F. Borrato, R. Barbosa, S. Yue and J.J. Jonas: In Thermec, 1988, pp. 383–90.

35. J. R. Yang, H. K. D. H. Bhadeshia, Adv Weld Technol Sci 1987, vol. 1, pp. 187-191.

36. R. A. Farrar, P. L. Harrison, J Mater Sci. 1987, vol. 22, pp. 3812-3820.

37. A. P. Reynolds, W. Tang, T. Gnaupel-Herold, H. Prask, Scripta Mater. 2003, vol. 48, pp. 1289-1294.

38. H. K. D. H. Bhadeshia, T. Debroy, Sci. Technol. Weld. Joining 2009, vol. 14, pp. 193-196.

39. U. F. H. R. Suhuddin, S. Mironov, Y. S. Sato, H. Kokawa, C. W. Lee, Acta Mater. 2009, vol. 57, pp. 5406-5418.

40. Y. S. Sato, T. W. Nelson, C. J. Sterling, R. J. Steel, C. O. Pettersson, Mater. Sci. Eng., A 2005, vol. 397, pp. 376-384.

41. Y. S. Sato, H. Yamanoi, H. Kokawa, T. Furuhara, Scripta Mater. 2007, vol. 57, pp. 557-60.

S. Gourdet, F. Montheillet, Acta Mater., 2003, vol. 51, pp. 2685-2699.

43. X. J. Zhang, P. D. Hodgson, P. F. Thomson, J. Mater. Process. Technol. 1996, vol. 60, pp. 615 - 619.

44. P. D. Hodgson, M. R. Hickson, R. K. Gibbs, Mater. Sci. Forum 1998, vol. 284-286, pp. 63-72.

R. Priestner, E. delosRios, Met. Technol. 1980, vol. 7, pp. 309 - 316.

46. P. J. Hurley, P.D. Hodgson, Mater. Sci. Eng., A 2001, vol. 302, pp. 206 - 214.

47. L. Y. Wei, T. W. Nelson, Mater. Sci. Eng., A 2012, vol. 556, pp. 51 - 59.

48. D. Zhang, H. Terasaki, Y. Komizo, Acta Mater. 2010, vol. 58, pp. 1369 - 1378.

49. F. R. Xiao, B. Liao, Y. Y. Shan, G. Y. Qiao, Y. Zhong, C. L. Zhang, K. Yang, Mater. Sci. Eng., A 2006, vol. 431, pp. 41-52.

50. P. J. Withers, H. K. Bhadeshia, Mater. Sci. Technol. 2001, vol. 17, pp. 366 - 375.

51. P. J. Withers, H. K. D. H. Bhadeshia, Mater. Sci. Technol. 2001, vol. 17, pp. 355 - 365.

52. R. W. Fonda, J. F. Bingert, K. J. Colligan, Scripta Mater. 2004, vol. 51, pp. 243 - 248.

53. P. B. Prangnell, C. P. Heason, Acta Mater. 2005, vol. 53, pp. 3179 - 3192.

54. R. Nanadan, T. DebRoy, H. K. D. H. Bhadeshia, Prog. Mater Sci. 2008, vol. 53, pp. 980 - 1023.

55. P. S. Davies, B. P. Wynne, W. M. Rainforth, M. J. Thomas, P. L. Threadgill, Metall. Mater. Trans. A 2011, vol. 42, pp. 2278 - 2289.

56. R. W. Fonda, K. E. Knipling, Sci. Technol. Weld. Joining 2011, vol. 16, pp. 288 - 294.

57. F. Montheillet, M. Cohen, J. J. Jonas, Acta Metall. 1984, vol. 32, pp. 2077 - 2089.

58. J. Baczynski, J. J. Jonas, Acta Mater. 1996, vol. 44, pp. 4273 - 4288.

59. S. Li, I. J. Beyerleinb, M. Bourkea, Mater. Sci. Eng., A 2005, vol. 394, pp. 66 - 77.

60. G. Kurdjumove, G. Z. Sachs, Physics 1930, vol. 64, pp. 325 - 343.

61. Y. He, S. Godet, J. J. Jonas, Acta Mater. 2005, vol. 53, pp. 1179-1190.

62. Y. He, S. Godet, P. J. Jacques, J. J. Jonas, Acta Mater. 2006, vol. 54, pp. 1323-1334.

63. K. E. Knipling, R. W. Fonda, Scripta Mater. 2009, vol. 60, pp. 1097 - 1100.

64. M. Abbasi, T. W. Nelson, C. D. Sorensen, Metall. Mater. Trans. A 2012, vol. 43, pp. 4940 - 4946.

Acknowledgements

The authors would like to acknowledge the support provided by the Advanced Forming Research Centre (AFRC), University of Strathclyde, which receives partial financial support from the UK’s High Value Manufacturing CATAPULT. Dr N. A. McPherson, formerly of BAE Systems Marine, Govan, Glasgow, is thanked for providing the FSW specimens.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 8, 2016.

Rights and permissions

About this article

Cite this article

Rahimi, S., Wynne, B.P. & Baker, T.N. Development of Microstructure and Crystallographic Texture in a Double-Sided Friction Stir Welded Microalloyed Steel. Metall Mater Trans A 48, 362–378 (2017). https://doi.org/10.1007/s11661-016-3833-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3833-8