Abstract

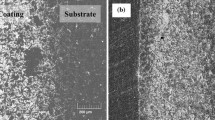

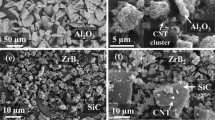

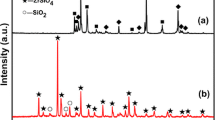

In this research, it was found that the C/SiC transition interface thickness increases without a significant decrease in toughness by modifying the reactive melt infiltration method through the addition of SiC nanoparticles. Also, the effect of the infiltration temperature on the transition interface thickness, isothermal oxidation behavior, and thermal shock resistance of the C/SiC graded coating were investigated. Coatings were characterized by X-ray diffraction, electron probe microanalysis, and scanning electron microscopy with energy-dispersive spectroscopy. Microstructural observations showed that with an increase in the heat treatment temperature, a higher amount of β-SiC (as a product of the infiltration process) is produced, which results in lower surface continuity in the coatings produced at a lower temperature. Moreover, the transition interface thickness increased with a decreasing infiltration temperature. The addition of SiC nanoparticles increased the transition interface thickness and oxidation resistance. After isothermal oxidation at 1773 K (1500 °C) for 10 hours, samples containing 7 wt pct SiC nanoparticles heat treated at 1773 K and 1873 K (1500 °C and 1600 °C) showed 13.3 and 5.03 pct weight loss, respectively.

Similar content being viewed by others

References

Z.-K. Chen, X. Xiong, G.-D. Li, and Y.-L. Wang: Appl. Surf. Sci., 2009, vol. 255, pp. 9217–23.

M.C. Halbig, J.D. McGuffin‐Cawley, A.J. Eckel, and D.N. Brewer: J. Am. Ceram. Soc., 2008, vol. 91, pp. 519–26.

J.D. Buckley and D. Dale Edie: Carbon–Carbon Materials and Composites, William Andrew, 1993.

Y. Ye, H. Zhang, Y. Tong, and S. Bai: Ceram. Int., 2013, vol. 39, pp. 5477-83.

F. Qian-Gang, L. He-Jun, S. Xiao-Hong, L. Ke-Zhi, W. Jian, and H. Min: Mater. Lett., 2006, vol. 60, pp. 431–34.

C. Hu, Y. Niu, H. Li, M. Ren, X. Zheng, and J. Sun: J. Therm. Spray Technol., 2012, vol. 21, pp. 16–22.

H. Jafari, N. Ehsani, S.A. Khalifeh-Soltani, and M. Jalaly: Appl. Surf. Sci., 2013, vol. 264, pp. 128–32.

Z.J. Dong, S.X. Liu, X.K. Li, A. Westwood, G.M. Yuan, Z.W. Cui, and Y. Cong: Ceram. Int., 2015, vol. 41, pp. 797–811.

L. Cheng, Y. Xu, L. Zhang, and X. Luan: Carbon, 2002, vol. 40, pp. 2229–34.

Y. Xin, Z.-An SU, Q.-Zhong Huang, and L.-Yuan Chai: Trans. Nonferr. Metal. Soc. China, 2012, vol. 22, pp. 2997–3002.

C. Sun, H-Jun Li, Q.-Gang Fu, H.-Liang Li, Y.-Jie Wang, and H. Wu: J. Therm. Spray Technol, 2013, vol. 22, pp. 525–30.

W. Yang, L. Zhang, L. Cheng, Y. Liu, and W. Zhang: Appl. Compos. Mater., 2009, vol. 16, pp. 83–92.

L. Li, H. Li, H. Lin, L. Zhuang, S. Wang, T. Feng, X. Yao, and Q. Fu: Surf. Coat. Technol., 2016, vol. 302, pp. 56–64.

J.I. Kim, W.-J. Kim, D.J. Choi, J.Y. Park, and W.-S. Ryu: Carbon, 2005, vol. 43, pp. 1749–57.

P.C. Kang, G.Q. Chen, B. Zhang, G.H. Wu, S. Mula, and C.C. Koch: Surf. Coat. Technol., 2011, vol. 206, pp. 305–11.

A. Abdollahi, N. Ehsani, and Z. Valefi: Mater. Chem. Phys., 2016, vol. 182, pp. 49-61.

Y. Niu, X. Zheng, C. Ding, H. Li, C. Hu, M. Ren, and J. Sun: Ceram. Int., 2011, vol. 37, pp. 1675-80.

X. K. Li, L. Liu, Y.X. Zhang, S.H.D. Shen, S.H. Ge, and L.C. Ling: Carbon, 2001, vol. 39, pp. 159-65.

H.-J. Choi and J.-G. Lee: J. Mater. Sci., 1995, vol. 30, pp. 1982–86.

Y.-J. Lee and H.J. Joo: Surf. Coat. Technol., 2004, vol. 180, pp. 286–89.

H. Jian-Feng, Z. Xie-Rong, L. He-Jun, X. Xin-Bo, and F. Ye-wei: Carbon, 2004, vol. 42, pp. 1517–21.

ASM HandBook: Volume 3 Alloy Phase Diagram. ASM International, Materials Park, 1992.

J. Li, R. Luo, Y. Chen, Q. Xiang, C. Lin, P. Ding, N. An, and J. Cheng: Appl. Surf. Sci., 2008, vol. 255, pp. 1967–74.

Z. Liu, Q. Guo, L. Liu, J. Shi, and G. Zhai: Surf. Coat. Technol., 2008, vol. 202, pp. 3094–99.

F. Qian-Gang, L. He-Jun, L. Ke-Zhi, S. Xiao-Hong, H. Zhi-Biao, and H. Min: Carbon, 2006, vol. 44, pp. 1866–69.

H. Li, Y. Wang, Q. Fu, and G. Sun: Surf. Coat. Technol., 2014, vol. 245, pp. 49–54.

X. Lu, Y. Wei, H. Wang, J. Wen, J. Zhou, and J. Fan: J. Mater. Sci. Technol., 2014, vol. 30, pp. 1217–22.

X. Li, P. Wu, and D. Zhu: Ceram. Int., 2014, vol. 40, pp. 4897–902.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted June 13, 2016.

Rights and permissions

About this article

Cite this article

Abdollahi, A., Ehsani, N. C/SiC Gradient Oxidation Protective Coating on Graphite by Modified Reactive Melt Infiltration Method: Effects of Processing Parameters on Transition Interface Thickness and High-Temperature Anti-oxidation Behavior. Metall Mater Trans A 48, 265–278 (2017). https://doi.org/10.1007/s11661-016-3813-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3813-z