Abstract

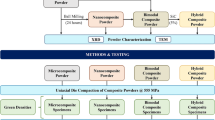

In the present study, Fe-10 vol pct Al2O3 in situ nanocomposite has been derived by high-energy ball milling of Fe2O3-Fe-Al powder mixture followed by the consolidation using spark plasma sintering (SPS). The consolidated nanocomposite has bimodal-grained structure consisting of nanometer- and submicron-sized Fe grains along with nanometer-sized Al2O3, and Fe3O4 particles. The mechanical property analysis reveals that compressive yield strength of Fe-10 vol pct Al2O3 nanocomposite is 2100 MPa which is nearly two times higher than that of monolithic Fe processed by Mechanical Milling and SPS. The strengthening contributions obtained from matrix, grain size, and particles in the synthesized nanocomposite have been calculated theoretically, and are found to be matching well with the experimental strength levels.

Similar content being viewed by others

References

R. Casati and M. Vedani, Metals, 4 (2014) p. 65–83.

B.S. Murty and S. Ranganathan, Int. Mater. Rev. 43 (1998) p. 101–41.

P. Matteazzi and G. Le Caer, J. Am. Cerm. Soc. 75 (1992) p.2749–53.

G.B. Schaffer and P.G. McCormick, Metall. Mater. Trans. A 21 (1990) p.2789–94.

X. Shengqi, Q. Xiaoyan, M. Mingliang, Z. Jingen, Z. Xiulin and W. Xiaotian, J. Alloys Comp. 268 (1998) p.211–4.

D.Y. Ying and D.L. Zhang, Mater. Sci. Eng. A 286 (2000) p.152–6.

D. Oleszak and M. Krasnowski, Mater. Sci. Forum 360-362 (2001) p.235–40.

D. Oleszak, J. Mater. Sci. 39 (2004) p.5169–74.

J. Li, F. Li and K. Hu, J. Mater. Proc. Tech. 147 (2004) p.236–40.

S.J. Hwang and J.H. Lee, Mater. Sci. Eng. A405 (2005) p.140–6.

T.Venugopal, K. Prasad Rao and B.S. Murty, Mater. Sci. Eng. A 393 (2005) p.382–6.

B.S.B. Reddy, K. Rajasekhar, M. Venu, J.J.S. Dilip, S. Das and K. Das, J. Alloys. Compd. 465 (2008) p.97–105.

J.B. Fogagnolo, E.M.J.A. Pallone, D.R. Martin, C.S. Kiminami, C. Bolfarini and W.J. Botta, J. Alloys. Compd. 471 (2009) p.448–52.

S.Z. Anvari, F. Karimzadeh and M.H Enayati, J. Alloys. Compd. (2009) 477 p. 178–81.

V. Udhayabanu, K.R. Ravi, V. Vinod, B.S. Murty Intermetallics, 18(3) (2010) p 353–8.

V. Udhayabanu, K. R. Ravi, K. Murugan, D. Sivaprahasam and B. S. Murty Metallurgical and Materials Transactions A, 2011, vol. 42(7), 2085-93.

V. Udhayabanu, K. R. Ravi, and B. S. Murty Journal of Alloys and Compounds 509S (2011) S223–8.

V. Udhayabanu, K.R. Ravi, B.S. Murty. Mater. Sci. Eng. A, 585 (2013) p 379-86.

M. P. Horvath and L. Takacs. IEEE Trans. magnetic, 28 (1992) p. 3186–8.

L. Takacs, Mater. Lett. 13 (1992) p.119–24.

P. Matteazzi, F Miani and D. Basset, Nanostruct. Mater. 2 (1993) p. 355–60.

P.M. Botta, R.C. Mercader, E.F. Aglietti and J.M. Porto Lopez, Scr. Mater. 48 (2003) p.1093–8.

K. Isonishi, M. Hashii and K. Ameyama, JSME International Journal Series A 49(2) (2006) p.229–36.

K.R.Ravi, A. Murugesan, V.Udhayabanu, R. Subramanian and B.S.Murty Mater. Sci. Forum 710 (2012) p 291–6.

M. Khodaei, M. H. Enayati and E.F. Karimzadeh, J. Mater. Sci. 43 (2008) p.132–8.

R. Orrù, R. Licheri, A. M. Locci, A. Cincotti, G. Cao, Mater. Sci. Engg: R. 63 (2009) p 127 – 287.

B. Srinivasarao, K. Oh-ishi, T. Ohkubo, T. Mukai and K. Hono, Scr. Mater. 58 (2008) 759-62.

K. Oh-ishi, H.W. Zhang, T. Ohkubo and K. Hono, Mater. Sci. Eng. A 456 (2007) p.20–7

Y.Long, T.Wang, H.Y.Zhang, X.L.Huang, Mater. Sci. Eng. A 608 (2014) p.82-9.

D. Tingaud, P. Jenei, A. Krawczynska, F.Mompiou, J. Gubicza, G. Dirras, Mater. Char. 99 (2015) p 118–27

Z. Li, Z. Lua, R. Xiea, C. Lua, C. Liu, Mater. Sci. Eng. A 660 (2016) p.52-60.

T.H. De Keijser, J.I. Langford, E.J. Mittemeijer and A.B.P. Vogel, J.Appl. Crys., 15 (1982) p.308–14.

I. Cvijovic, M. Vilotijevic and T.J.Milan, Mater. Char. 57 (2006) p. 94–9.

G. Ji, T. Grosdidier, N. Bozzolo and S. Launois, Intermetallics 15 (2007) p.108–18.

D. Jia, K.T. Ramesh and E. Ma, Acta Mater. 51 (2003) p.3495–509.

J.E. Carsley, W.W. Milligan, S.A. Hackney and E.C. Aifantis, Metall. Mater. Trans. A 26 (1995) p.2479–81.

J. Rawers, R. Krabbe and N. Duttlinger, Mater. Sci. Eng. A 230 (1997) p.139–45.

A. Munitz, Z. Livne, J.C. Rawers, J.S. Adams and R.J. Fields, Nanostruct. Mater. 11(2) (1999) p.159–77.

B.Q. Han, E.J. Lavernia and F.A. Mohamed, Metall. Mater. Trans. A 34 (2003) p.71–83.

Q. Wei, L. Kecskes, T. Jiao, K.T. Hartwig, K.T. Ramesh and E. Ma, Acta Mater. 52 (2004) p.1859–69.

J.S.C. Jang, and C.C. Koch, Scr. Metall. Mater., 24 (1990) p.1599–604.

M. Zhu and H.J. Fecht, Nanostruct.Mater. 6 (1995) p.921–4.

G.E. Fougere, J.R. Weertman and R.W. Siegel, Nanostruct. Mater. 5 (1995) p.127–34.

J. Rawers, G. Slavens, D. Govier, D. Dogan and R. Doan, Metall. Mater. Trans. A 27 (1996) p.3126–34.

R.K. Guduru, R.O. Scattergood, C.C. Koch, K.L. Murty, S. Guruswamy and M.K. McCarter, Scripta Mater.54 (2006) p.1879–83.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 19, 2015.

Rights and permissions

About this article

Cite this article

Udhayabanu, V., Ravi, K.R. & Murty, B.S. Structure–Property Correlation in Fe-Al2O3 In Situ Nanocomposite Synthesized by High-Energy Ball Milling and Spark Plasma Sintering. Metall Mater Trans A 47, 5223–5233 (2016). https://doi.org/10.1007/s11661-016-3627-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3627-z