Abstract

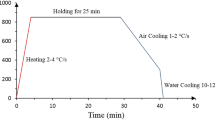

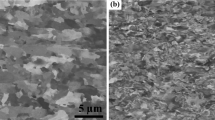

The microstructure and fracture toughness K IC (or K Q) of railway wheel steel with 0.53 wt pct C were studied under various heating rates. The effects of the heating rate on the grain size and the relation between the grain size and the fracture toughness were discussed. The results show that rapid heating not only refines the grains but can also result in more homogeneous grains. The cleavage fracture toughness strongly relates to the grains with larger size. It can be observed that under different heating rates, the fracture toughness K Q increases with decreasing average diameter of the top 5 pct grains D 5. K Q (MPa m1/2) = 194.3–29.8 ln(D 5) when D 5 is in the range of 30 to 73 μm. This result can be interpreted by the cleavage fracture critical event, which is grain-sized crack propagation controlled.

Similar content being viewed by others

References

T. Oda and R. Yanagimoto: Heat Treatment of steel, p. 8, Iron steel Inst. Jap., Tokyo, Maruzen, 1969.

N. C. Law and D. V. Edmonds: Metall. Trans. A, 1980, vol. 11, pp. 33-46.

H.A. Richard, M. Fulland, M. Sander, and G. Kullmer: Eng. Fail. Anal., 2005, vol.12,pp. 986-99.

M.R. Zhang and H.C. Gu: Eng. Frac. Mech., 2008, vol.75, pp. 5113-21.

F. B. Pickering: Constitution and properties of steels, p. 436, Weinheim, New York, Basel, Cambridge, VCH, 1992.

T. N. Baker: Yield, flow and fracture of polycrystals. p. 156, Elsevier Applied Science Publishers, London, 1983.

T. Gladman, I. D. McIvor, and F. B. Pickering: J. Iron Steel Inst. London, 1972, vol.210, pp. 916-30.

M. Dollar, I. M. Berstein, and A. W. Thompson: Acta Met., 1988, vol.36, pp. 311-20.

S. Lee, L. Majno, and R.J. Asaro: Metall. Trans. A, 1985, vol.16, pp. 1633-48.

S. K. Chaudhuri and R. Brook: Inter. Jour. Frac., 1976, vol.12, pp. 101-06.

I. Souki, D. Delagnes, and P. Lours: Procedia Eng., 2011, vol.10, pp. 631-37.

M.T. Miglin, J. P. Hirth and A. R. Rossenfield: Metall. Trans. A, 1983, vol.14, pp. 2055-61.

N. Sarafianos: Metall. Mater. Trans. A, 1997, vol. 28, pp. 2089-99.

A.V. Samant and J.J. Lewadowski: Metall. Mater. Trans. A, 1997, vol. 28, pp. 2297-307.

[15] T. Kawabata and O. Izumi: J. Mater. Sci., 1978, vol. 13, pp. 945-50.

D. Townsend and J. E. Field: J. Mater. Sci., 1990, vol. 25, pp. 1347-52.

Z. Y. Fan: Mater. Sci. Eng. A, 1995, vol. 191, pp. 73-83.

D. J. Alexander and I. M. Bernstein: Metall. Trans. A, 1989, vol. 20, pp. 2321-35.

G. Z.Wang and J. H. Chen: Inter. Jour. Frac., 2001, vol. 108, pp. 235-50.

J. H. Chen, G. Z. Wang, C. Yan, H. Ma, and L. Zhu: Inter. J. Frac., 1997, vol.83, pp. 105-20.

A. S. Kumara, B. R. Kumar, G. L. Dattac and V. R. Ranganath: Mater. Sci. Eng. A, 2010, vol. 527, pp. 954-60.

H. Sakamoto, K. Toyama and K. Hirakawa: Mater. Sci. Eng. A, 2000, vol. 285, pp. 288-92.

A. F. Vicente, M. Carsi, F. Penalba, E. Taleff and O. A. Ruano: Mater. Sci. Eng. A, 2002, vol. 335, pp. 175-185.

[24] S. Gong, X. C. Ren, Y. X. Ma, K. W. Gao, B. Jiang, G. Chen, H. Zhao: Trans. Mater. Heat Treat., 2015, vol. 36(4), pp.150-155.

A. A. Griffith: Phil. Trans. R. Soc. London, 1920, Vol. 221A, pp. 163-198.

G. R. Irwin: J. Appl. Mech., 1957, Vol. 24, pp. 361-364.

J. H. Chen, Q. Wang, G. Z. Wang and Z. Li: Acta Mater., 2003, vol.51, pp.1841-55.

R. A. Grange: Metall. Trans., 1971, vol.2, pp. 65-78.

[29]O. S. Vilyams, N. M. Bolshova and M. Y. Koval: Metall. Sci. Heat Treat., 1966, vol.7, pp. 817-20.

S. Primig, H. Leitner, W. Knabl, A. Lorich, H. Clemens and R. Stickler: Mater. Sci. Eng. A, 2012, vol. 535, pp. 316-24.

J. Wang, J. Li, X. F. Wang, J. J. Tian, C. H. Zhang and S. G. Zhang, J. Iron Steel Res. Int., 2010, vol. 17, pp. 54-61.

F.G. Caballero, C. Capdevila and C. Garcia de Andres: Metall. Mater. Trans. A, 2001, vol. 32, pp. 1283-91.

D. Martin, Y. Palizdar, C. Garcia-Mateo, R.C. Cochrane, R. Brydson, A.J. Scott, Metall. Mater. Trans. A, 2011, vol. 42, pp. 2591-608.

Acknowledgment

This research was supported by the National Natural Science Foundation of China under Grant Nos. 51171020, U1234207, and 51201008.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 27, 2014.

Rights and permissions

About this article

Cite this article

Ren, X., Qi, J., Gao, J. et al. Effects of Heating Rate on Microstructure and Fracture Toughness of Railway Wheel Steel. Metall Mater Trans A 47, 739–747 (2016). https://doi.org/10.1007/s11661-015-3264-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-3264-y