Abstract

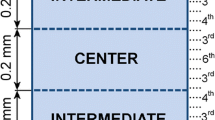

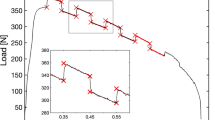

The limit in structural refinement of lamellar bands (LBs) generated during accumulative roll bonding (ARB) of commercially pure nickel was investigated by transmission electron microscopy and transmission Kikuchi diffraction. A typical LB consists of an internal cellular substructure of low angle boundaries (LABs) bounded by two high angle boundaries (HABs) that are aligned parallel to the rolling plane. At low true strains (ε < 2.4; 1 to 3 ARB cycles), the deformation substructure was distributed heterogeneously; nano-sized (~80 nm) equiaxed grains containing mainly HABs were generated in the vicinity of the roll bonding region of the individual nickel layers, whereas a typical dislocation substructure containing LABs was generated in their interior. At high strains (ε > 4.8; 6 to 10 ARB cycles), a homogenous distribution of well-defined, highly elongated LBs of average thickness 75 nm was generated throughout the entire thickness of the material. The thickness of these LBs decreased with increasing number of ARB cycles and reached a saturation thickness of ~75 nm after 6 to 8 cycles. A theoretical framework for the limit to LB refinement during ARB is presented based on the refinement rate due to the stored energy of deformation balanced by the growth rate caused by adiabatic heating. The analysis takes into account the unique features of LB structures and processing parameters.

Similar content being viewed by others

References

A. Azushima, R. Kopp, A. Korhonen, D.Y. Yang, F. Micari, G.D. Lahoti, P. Groche, J. Yanagimoto N. Tsuji, A. Rosochowski and A. Yanagida (2008) CIRP Ann. Manuf. Technol., vol. 57, pp. 716–35.

Y. Estrin and A. Vinogradov: Acta Mater., 2013, vol. 61, pp. 782–817.

Z. P. Luo, H. W. Zhang, N. Hansen and K. Lu: Acta Mater., 2012, vol. 60, pp. 1322–33.

X. Y. Qin, X. G. Zhu, S. Gao, L. F. Chi and J. S. Lee: Scripta Mater., 2002, vol. 46, pp. 611–16.

R. Pippan, S. Scheriau, A. Taylor, M. Hafok, A. Hohenwarter and A. Bachmaier: Annu Rev Mater Res, 2010, vol. 40, pp. 319–43.

F. Liu, Y. Zhang and J.T. Wang: Mater. Sci. Forum, 2011, vol. 667–669, pp. 319–24.

S.V. Zherebtsov, G.S. Dyakonov, A.A. Salem, V.I. Sokolenko, G.A. Salishchev and S.L. Semiatin: Acta Mater., 2013, vol. 61, pp. 1167–78.

N. Kamikawa, T. Sakai, N. Tsuji: Acta Mater., 2007, vol. 55, pp. 5873–88.

M.Z. Quadir, M. Ferry, O. Al-Buhamad, P.R. Munroe: Acta Mater., 2009, vol. 57, pp. 29–40.

A.P. Zhilyaev, S. Swaminathan, A.I. Pshenichnyuk, T.G. Langdon and T.R. McNelley: J. Mater. Sci., 2013, vol. 48, pp. 4626–36.

P.W. Trimby, Y. Cao, Z. Chen, S. Han, K.J. Hemker, J. Lian, X. Liao, P. Rottmann, S. Samudrala, J. Sun, J.T. Wang, J. Wheeler and J.M. Cairney: Acta Mater., 2014, vol. 62, pp. 69–80.

F.J. Humphreys, M. Hatherly: Recrystallization and Related Annealing Phenomena, Elsevier Press, Oxford, 2004.

L. Li, K. Nagrai and F.X. Yin: Sci. Technol. Adv. Mater., 2008, vol. 9, pp. 1–11.

S.H. Lee, Y. Saito, N. Tsuji, H. Utsunomiya and T. Sakai: Scripta Mater., 2002, vol. 46, pp. 281–85.

K.D. Lau, M.Z. Quadir and M. Ferry: Light Metals Technology, 2009, vol. 618–619, pp. 575–78.

S.H. Lee, Y. Sakai and H. Utsunomiya, Mater. Sci. Eng A, 2002, vol. 325, pp. 228–35.

H.J. Frost and M.F. Ashby: Deformation-Mechanism Maps, Pergamon Press, Oxford, 1982.

D.K. Yang, P. Cizek, P.D. Hodgson and C.E. Wen: Acta Mater., 2010, vol. 58, pp. 4536–48.

J. Hodowany, G. Ravichandran, A.J. Rosakis and P. Rosakis: Exp. Mech., 2000, vol. 40, pp. 113–23.

A.R. Wazzan: J. Appl. Phys., 1965, vol. 36, pp. 3596–99.

Y.R. Kolobov, G.P. Grabovetskaya, M.B. Ivanov, A.P. Zhilyaev and R.Z. Valiev: Scripta Mater., 2001, vol. 44, pp. 873–78.

D.A. Hughes and N. Hansen: Acta Mater., 2000, vol. 48, pp. 2985–3004.

Acknowledgments

The authors gratefully acknowledge the China Scholarship Council (CSC) for supporting this work. The authors also gratefully acknowledge the access to the University of New South Wales node of the Australian Microscopy and Microanalysis Research Facility (AMMRF).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 1, 2015.

Rights and permissions

About this article

Cite this article

Duan, J.Q., Quadir, M.Z. & Ferry, M. An Analytical Framework for Predicting the Limit in Structural Refinement in Accumulative Roll Bonded Nickel. Metall Mater Trans A 47, 471–478 (2016). https://doi.org/10.1007/s11661-015-3240-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-3240-6