Abstract

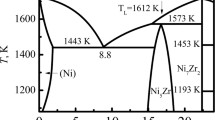

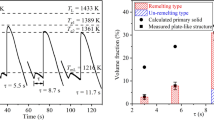

The drop-tube technique was used to solidify droplets of the Ni-25.3 at. pct Si alloy at high cooling rates. XRD, SEM, and TEM analysis revealed that the metastable phase, Ni25Si9, formed as the dominant phase in all ranges of the droplets, with γ-Ni31Si12 and β 1-Ni3Si also being present. Three different microstructures were observed: the regular and anomalous eutectic structures and near single-phase structure containing small inclusions of a second phase, termed here as heteroclite structure. Both eutectic structures comprise alternating lamellae of Ni25Si9 and β 1-Ni3Si, which, we conjecture, is a consequence of an unobserved eutectic reaction between the Ni25Si9 and β 1-Ni3Si phases. The matrix of the heteroclite structure is also identified as the metastable phase Ni25Si9, in which twined growth is observed in the TEM. As the cooling rate is increased (particle size decreased), the proportion of droplets displaying the entire heteroclite structure tends to increase, with its fraction increasing from 13.91 pct (300 to 500 µm) to 40.10 pct (75 to 106 µm). The thermodynamic properties of the Ni25Si9 phase were also studied by in-situ heating during XRD analysis and by DTA. This showed the decomposition of Ni25Si9 to β 1 and γ-Ni31Si12 for temperatures in excess of 790 K (517 °C).

Similar content being viewed by others

References

C.M. Ward-Close, R. Minor and P. Doorbar: Intermetallics, 1996, vol. 4, pp. 217–229.

C. Cui, J. Zhang, K. Wu, Y. Ma, L. Liu and H. Fu: Phys. B Condens. Matter, 2012, Vol. 407, pp. 3566-3569.

R.L. Fleischer: J. Mater. Sci., 1987, vol. 22, pp. 2281-2288.

E.M. Schulson, L.J. Briggs and I. Baker: Acta Metall. Mater., 1990, vol. 38, pp. 207-213.

N.S. Stoloff, C.T. Liu and S.C. Deevi: Intermetallics, 2000, vol. 8, pp. 1313-1320.

T. Takasugi, H. Suenaga and O. Izumi: J Mater Sci., 1991, vol. 26, pp. 1179–1186.

J.M. Yang: JOM, 1997, vol. 49, pp. 40–43.

M. Leonhardt, W. Löser and H.G. Lindenkreuz: Mater. Sci. Eng. A, 1999, vol. 271, pp. 31–37.

E. Çadırlı, D.M. Herlach and T. Volkmann: J. Non-Cryst. Solids, 2010, vol. 356, pp. 461–466.

H. Bei, G.M. Pharr and E.P. George: J. Mater. Sci., 2004, vol. 39, pp. 3975–3984.

R. Caram and S. Milenkovic: J. Cryst. Growth, 1999, vol. 198–199, pp. 844–849.

A.T. Dutra, P.L. Ferrandini and R. Caram: J. Alloy Compd., 2007, vol. 432, pp. 167–171.

S. Milenkovic and R. Caram: J. Cryst. Growth, 2002, vol. 237–239, pp. 95–100.

D.M. Herlach: Mater. Sci. Eng. R Rep., 1994, vol. 12, pp. 177–272.

E.M. Schulson and D.R. Barker: Scripta. Metall., 1983, vol. 17, pp. 519–522.

Y. Kaneno, M. Wada, H. Inoue, and T. Takasugi: Mater. Trans., vol. 42, pp. 418–21.

R.W. Cahn, P.A. Siemers, J.E. Geiger and P. Bardhan: Acta Metall., 1987, vol. 35, pp. 2737–2751.

R.W. Cahn, P.A. Siemers and E.L. Hall: Acta Metall., 1987, vol. 35, pp. 2753–2764.

F. Liu, Y. Chen, G. Yang, Y. Lu, Z. Chen and Y. Zhou: J. Mater. Res., 2007, vol. 22, pp. 2953–2963.

Y. Lu, N. Liu, T. Shi, D. Luo, W. Xu and T. Li: J. Alloy Compd., 2010, vol. 490, pp. L1–L4.

Y. Lu, F. Liu, G. Yang, H. Wang and Y. Zhou: Mater. Lett., 2007, vol. 61, pp. 987–990.

M. Schwarz A. Karma, K. Eckler and D.M. Herlach: Phys. Rev. Lett., 1994, vol. 73, pp. 1380–1383.

A.M. Mullis and R.F. Cochrane: J. Appl. Phys., 1997, vol. 82, pp. 3783–3790.

A.M. Mullis and R.F. Cochrane: Acta Mater., 2001, vol. 49, pp. 2205–2214.

R. Goetzinger, M. Barth and D.M. Herlach: Acta Mater., 1998, vol. 46, pp. 1647–1655.

A.T. Dutra, S. Milenkovic, C.S. Kiminami, A.M. Santino, M.C. Gonçalves and R. Caram: J. Alloy Compd., 2004, vol. 381, pp. 72–76.

R. Ahmad, R.F. Cochrane and A.M. Mullis: Intermetallics, 2012, vol. 22, pp. 55–61.

R.F. Cochrane, A.L. Greer, K. Eckler and D.M. Herlach: Mater. Sci. Eng. A., 1991, vol. 133, pp. 698–701.

Y. Lu, G. Yang, X Li and Y. Zhou: J. Mater. Sci. Technol., 2009, vol. 25, pp. 370–372.

L. Cao, R.F. Cochrane, and A.M. Mullis: J. Alloy Compd., in Press.

Mullis, A.M., L.G. Cao, R.F. Cochrane: Mater. Sci. Forum, 2014, vol. 790–791, pp. 22–27.

M. Ellner, S. Heinrich, M.K. Bhargava and K. Schubert: J. Less Common Met., 1979, vol. 66, pp. 163–173.

E. Karaköse and M. Keskin: J. Alloy Compd., 2012, vol. 528, pp. 63–69.

G. Kasperovich, T. Volkmann, L. Ratke, D.M. Herlach: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 1183–1191.

D.M. Herlach, R.F. Cochrane, I. Egry, H.J. Fecht and A.L. Greer: Int. Mater. Rev., 1993, vol. 38, pp. 273–347.

B. Wei, G. Yang and Y. Zhou: Acta Metall. Mater., 1991, vol. 39, pp. 1249–1258.

C.R. Clopet, R.F. Cochrane and A.M. Mullis: Acta Mater., 2013, vol. 61, pp. 6894–6902.

J.F. Li, W.Q. Jie, S. Zhao and Y.H. Zhou: Metall. Mater. Trans. A, 2007, vol. 38A, pp. 1806–1816.

G.A. Bertero, W.H. Hofmerster, M.B. Robinson and R.J. Bayuzick: Metall. Trans. A, 1991, vol. 22A, pp. 2723–2732.

H. Fredriksson and T. Nylen: Met. Sci., 1982, vol. 16, pp. 283–294.

D.H. StJohn: Acta Metall. Mater., 1990, vol. 38, pp. 631–636.

N.J.W. Barker and A. Hellawell: Met. Sci., 1974, vol. 8, pp. 353–356.

L. Bendersky, F.S. Biancaniello, W.J. Boettinger and J.H. Perepezko: Mater. Sci. Eng., 1987, vol. 89, pp. 151–159.

Acknowledgment

The authors acknowledge financial supports of the China Scholarship Council (CSC)—University of Leeds scholarship program.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript Submitted August 1, 2014.

Rights and permissions

About this article

Cite this article

Cao, L., Cochrane, R.F. & Mullis, A.M. Microstructural Evolution and Phase Formation in Rapidly Solidified Ni-25.3 At. Pct Si Alloy. Metall Mater Trans A 46, 4705–4715 (2015). https://doi.org/10.1007/s11661-015-3070-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-3070-6