Abstract

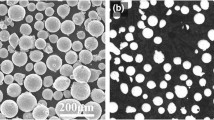

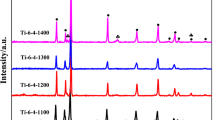

An array of eight long Ti-6Al-4V rods (diameter: 12 mm; height: 300 mm) have been additively manufactured, vertically and perpendicular to the powder bed, by selective electron beam melting (SEBM). The purpose was to identify and understand the challenges of fabricating Ti-6Al-4V samples or parts from a deep powder bed (more than 200-mm deep) by SEBM and the necessity of applying post heat treatment. The resulting microstructure and mechanical properties of these Ti-6Al-4V rods were characterized along their building (i.e., axial) direction by dividing each rod into three segments (top, middle, and bottom), both before (i.e., as-built) and after hot isostatic pressing (HIP). The as-built microstructure of each rod was inhomogeneous; it was coarsest in the top segment, which showed a near equilibrium α-β lamellar structure, and finest in the bottom segment, which featured a non-equilibrium mixed structure. The tensile properties varied along the rod axis, especially the ductility, but all tensile properties met the requirements specified by ASTM F3001-14. HIP increased the relative density from 99.03 pct of the theoretical density (TD) to 99.90 pct TD and homogenized the microstructure thereby leading to highly consistent tensile properties along the rod axis. The temperature of the stainless steel substrate used in the powder bed was monitored. The as-built inhomogeneous microstructure is attributed to the temperature gradient in the deep powder bed. Post heat treatment is thus necessary for Ti-6Al-4V samples or parts manufactured from a deep powder bed by SEBM. This differs from the additive manufacturing of small samples or parts from a shallow powder bed (less than 100-mm deep) by SEBM.

Similar content being viewed by others

References

X.Y. Cheng, S.J. Li, L.E. Murr, Z.B. Zhang, Y.L. Hao, R. Yang, F.Medina, R.B.Wicker: J. Mech. Behav. Biomed. Mater., 2012, vol. 16, pp. 153–162.

V. Juechter, T. Scharowsky, R.F. Singer, C. Körner: Acta Materialia, 2014, vol. 76, pp. 252–58.

H.P. Tang, M. Qian, N. Liu, X.Z. Zhang, G.Y. Yang, J. Wang: JOM, 2015, vol. 67, pp. 555–63.

W. Xu, M. Brandt, S. Sun, J. Elambasseril, Q. Liu, K. Latham, K. Xia, M. Qian: Acta Materialia 2015, vol. 85, pp. 74–84.

D. Whittaker: Powder Metallurgy Review, 2014, vol. 3, pp. 53–59.

A. Safdar, L.Y. Wei, A. Snis, Z. Lai: Mater. Charact., 2012, vol. 65, pp. 8–15.

L.E. Murr, E.V. Esquivel, S.A. Quinones, S.M. Gaytan, M.I. Lopez, E.Y. Martinez, F. Medina, D.H. Hernandez, E. Martinez, J.L. Martinez, S.W. Stafford, D.K. Brown, T. Hoppe, W. Meyers, U. Lindhe, R.B. Wicker: Mater. Charact., 2009, vol. 60, pp. 96–105.

S.S. Al-Bermani, M.L. Blackmore, W. Zhang, I.Todd: Metall. Mater. Trans. A, 2010, vol. 41A, pp. 3422–34.

A.B. Arcam. Arcam Annual Report 2012. http://www.arcam.com. Accessed on 20 December 2014.

http://software.materialise.com/sites/default/files/public/SAM/Others/arcam.pdf Accessed on 19 December 2014.

F3001-14 A. Standard Specification for Additive Manufacturing Titanium-6 Aluminum-4 Vanadium ELI (Extra Low Interstitial) with Powder Bed Fusion, West Conshohocken, PA, ASTM, 2014.

E8/E8M. Standard Test Methods for Tension Testing of Metallic Materials, West Conshohocken, PA, ASTM, 2012.

G. Welsch, R. Boyer, E.W. Collings: Materials Properties Handbook: Titanium Alloys, ASM International, Materials Park, OH, USA, 1994, pp. 488.

G. Lütjering and J.C. Williams: Titanium, 2nd ed., Springer, Berlin, 2003, pp. 42–44.

Acknowledgments

This work is supported in part by the International Science and Technology Cooperation Programme (2011DFA52590) of the Ministry of Science and Technology China and the Australian Research Council (ARC) through the Discovery Grant (DP120101672). Dr Bin Liu of Central South University China is acknowledged for his assistance with the EBSD work. Shenglu Lu further acknowledges the support of a visiting scholarship from the China Scholarship Council (CSC). Useful and in-depth comments and suggestions received from the reviewers are acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Manuscript submitted March 3, 2015.

Rights and permissions

About this article

Cite this article

Lu, S.L., Tang, H.P., Ning, Y.P. et al. Microstructure and Mechanical Properties of Long Ti-6Al-4V Rods Additively Manufactured by Selective Electron Beam Melting Out of a Deep Powder Bed and the Effect of Subsequent Hot Isostatic Pressing. Metall Mater Trans A 46, 3824–3834 (2015). https://doi.org/10.1007/s11661-015-2976-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-2976-3