Abstract

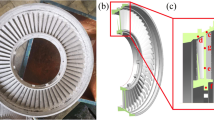

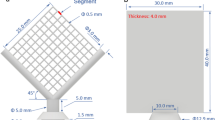

Development of investment casting process has been a challenge for manufacturers of complex shape parts. Numerous experimental casting trials are typically carried out to determine the optimum casting parameters for fabrication of high-quality products. In this work, it is demonstrated that physical simulation of investment casting can successfully predict microstructure and hardness in as-cast complex shape parts. The physical simulation tool consists of a thermal model and melting/solidification experiments in thermo-mechanical simulator. The thermal model is employed to predict local cooling rate during solidification at each point of a casting. Melting/solidification experiments are carried out under controlled cooling rates estimated by the thermal model. Microstructural and mechanical characterization of the solidified specimens is performed; the obtained results predict the local microstructure and mechanical properties of the casting. This concept is applied to investment casting of complex shape nozzle guide vanes from Mar-M247 Ni-based superalloy. Experimental casting trials are performed and the outcomes of physical simulation tool are validated against experimental results. It is shown that phase composition, secondary dendrite arm spacing, grain size, γ/γ′ eutectic size and volume fraction, size and shape of carbide particles, and local microhardness can be predicted at each point of the casting via physical simulation.

Similar content being viewed by others

References

S. Pattnaik, D. B. Karunakar and P. K. Jha: J. Mater. Proc. Tech. 2012, vol. 212, pp. 2332-2348.

R.C. Reed: The Superalloys: Fundamentals and Applications, Cambridge University Press, Cambridge, 2006.

S.T. Mandziej: Mater. Tehnol. 2010, vol. 44, pp. 105-119.

R. W. Hamilton, D. See, S. Butler and P. D. Lee: Mater. Sci. Eng. A, 2003, vol. 343, pp. 290-300.

M. Gonzalez, M. Goldschmit, A. Assanelli, E. Dvorkin and E. Berdaguer: Metall. Mater. Trans. B, 2003, vol. 34, pp. 455-473.

J. Guo and M. Samonds: Modeling of Casting and Solidification Processes, vol. 22B, ASM International, Metals Park, 2010, pp. 168–95.

H.G. Suzuki, S. Nishimura, and S. Yamaguchi: Proc: Physical Simulation of Welding, Hot Forming and Continuous Casting, CANMET, Canada, 1988.

J. Michalik and C. Kolmasiak: Metalurgija, 2009, vol. 48, pp. 71-74.

D. Ferguson, W. Chen, T. Bonesteel and J. Vosburgh: Mater. Sci. Eng. A, 2009, vol. 499, pp. 329-332.

H. Y. Bor, C. N. Wei, R. R. Jeng and P. Y. Ko: Mater. Chem. Phy., 2008, vol. 109, pp. 334-341.

ProCast User Manual & Technical Reference, ESI Software, France, 2007.

M. Rappaz, M. Bellet, and M.O. Deville: Numerical Modelling in Materials Science and Engineering, Springer-Verlag, Berlin, 2002.

A.J. Torroba, O. Koeser, L. Calba, L. Maestro, E. Carreno-Morelli, M. Rahimian, S. Milenkovic, I. Sabirov, J. LLorca: Integr. Mater. Manuf. Innov., 2014, vol. 3, 25.

E. Anglada, A. Meléndez, L.Maestro and I. Domiguez: Proc. Eng., 2013, vol. 63, pp. 75-83.

M. Rahimian, S. Milenkovic and I. Sabirov: Phil. Mag. Lett., 2014, vol. 94, pp. 86-94.

Y. Zhang, B. Huang and J. Li: Metall. Mater. Trans. A, 2013, vol. 44, pp. 1641-1644.

W. Kurz and D.J. Fisher: Fundamentals of Solidification, 4th edn., Trans Tech Publications, Aedermannsdorf, Switzerland, 1998.

A. Szczotok and K. Rodak: IOP Conference Series: Materials Science and Engineering, 2012, vol. 35, p. 012006.

L. Liu, F. Sommer and H. Z. Fu: Scripta Metall. Mater., 1994, vol. 30, pp. 587-591.

L. Z. He, Q. Zheng, X. F. Sun, G. C. Hou, H. R. Guan and Z. Q. Hu: J. Mater. Sci., 2005, vol. 40, pp. 2959-2964.

S. M. Seo, J. H. Lee, Y. S. Yoo, C. Y. Jo, H. Miyahara and K. Ogi: Metall. Mater. Trans. A, 2011, vol. 42, pp. 3150-3159.

C. Liu, J. Shen, J. Zhang and L. Lou: J. Mater. Sci. Tech., 2010, vol. 26, pp. 306-310.

S. Milenkovic, I. Sabirov and J. Llorca: Mater. Lett. 2012, vol. 73, pp. 216-219.

S. Milenkovic, M. Rahimian and I. Sabirov: Metall. Mater. Trans. B, 2014, vol. 45, pp. 482-488.

K. L. Gasko, G. M. Janowski and B. J. Pletka: Mater. Sci. Eng. A, 1988, vol. 104, pp. 1-8.

Acknowledgments

This investigation was carried out in frame of the VANCAST project (EU, FP7, ERA-NET MATERA+). SM and IS acknowledge gratefully the Spanish Ministry of Economy and Competitiveness for financial support through the Ramon y Cajal fellowships.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted October 17, 2014.

Rights and permissions

About this article

Cite this article

Rahimian, M., Milenkovic, S., Maestro, L. et al. Physical Simulation of Investment Casting of Complex Shape Parts. Metall Mater Trans A 46, 2227–2237 (2015). https://doi.org/10.1007/s11661-015-2815-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-2815-6