Abstract

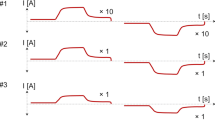

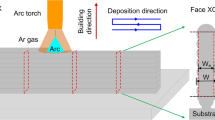

Metallic additive manufacturing processes generally utilize a conduction mode, welding-type approach to create beads of deposited material that can be arranged into a three-dimensional structure. As with welding, the cooling rates in the molten pool are relatively rapid compared to traditional casting techniques. Determination of the cooling rate in the molten pool is critical for predicting the solidified microstructure and resultant properties. In this experiment, wire-fed electron beam additive manufacturing was used to melt aluminum alloy 2219 under different thermal boundary conditions. The dendrite arm spacing was measured in the remelted material, and this information was used to estimate cooling rates in the molten pool based on established empirical relationships. The results showed that the thermal boundary conditions have a significant effect on the resulting cooling rate in the molten pool. When thermal conduction is limited due to a small thermal sink, the dendrite arm spacing varies between 15 and 35 µm. When thermal conduction is active, the dendrite arm spacing varies between 6 and 12 µm. This range of dendrite arm spacing implies cooling rates ranging from 5 to 350 K/s. Cooling rates can vary greatly as thermal conditions change during deposition. A cooling rate at the higher end of the range could lead to significant deviation from microstructural equilibrium during solidification.

Similar content being viewed by others

References

I. Gibson, D.W. Rosen, B. Stucker: Additive Manufacturing Technologies, Springer, New York, NY, 2010.

K.M.B. Taminger and R.A. Hafley: Proceedings of the 3rd Annual Automotive Composites Conference, Sept. 9-10, Troy, MI, 2003, pp. 9–10.

B.H. Alexander and F. N. Rhines: Trans. AIME, 1950, vol. 188, pp. 1267-1273.

A.B. Michael and M.B. Bever: Trans. AIME, 1954, vol. 200, pp. 47-56.

J.A. Horwath and L.F. Mondolfo: Acta Metall., 1962, vol. 10, pp. 1037-1042.

T.F. Bower, H.D. Brody, and M.C. Flemings: Trans. AIME, 1966, vol. 236, pp. 624-634.

K.P. Young and D.H. Kirkwood: Metall. Trans. A, 1975, vol. 6A, pp. 197-205.

D.G. McCartney and J.D. Hunt: Acta Metall., 1981, vol. 29, pp. 1851-1863.

A. Munitz: Metall. Trans. B, 1985, vol. 16B, pp. 149-161.

J.A. Sarreal and G.J. Abbaschian: Metall. Trans. A, 1986, vol. 17A, pp. 2063-2073.

T. Kraft, A. Roósz, and M. Rettenmayr: Scripta Mater., 1996, vol. 35 (1), pp. 77-82.

D. Bouchard and J.S. Kirkaldy: Metall. Mater. Trans. B, 1997, vol. 28B, pp. 651-663.

D. Eskin, Q. Du, D. Ruvalcaba, and L. Katgerman: Mater. Sci. Engr. A, 2005, vol. 405, pp. 1-10.

G. Kasperovich, T. Volkmann, L. Ratke, and D. Herlach: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 1183-1191.

C.A. Gandin, S. Mosbah, T. Volkmann, and D.M. Herlach: Acta Mater., 2008, vol. 56, pp. 3023-3035.

A.M. Mullis, L. Farrell, R.F. Cochrane, and N.J. Adkins: Metall. Mater. Trans. B, 2013, vol. 44B, pp. 992-999.

T. Sivarupan, C.H. Caceres, and J.A. Taylor: Metall. Mater. Trans. A, 2013, vol. 44A, pp. 4071-4080.

I. Lichioiu, I. Peter, B. Varga, and M. Rosso: J. Mater. Sci. Technol., 2014, vol. 30(4), pp. 394-400.

M.C. Flemings: Solidification Processing, McGraw-Hill Book Co., New York, NY, 1974, pp. 146-154.

C.A. Brice and W.H. Hofmeister: Metall. Mater. Trans. A, 2013,vol. 44A, pp. 5147-5153.

R.J. Messler, Jr.: Principles of Welding, John Wiley & Sons, Inc., New York, NY, 1999, pp. 175-176.

Acknowledgements

The authors gratefully acknowledge Mr. Richard Martin, Mr. Harold Claytor, and Mr. James Baughman of the NASA Langley Research Center for their assistance in the fabrication trials, sample preparation, and data collection.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 30, 2014.

Rights and permissions

About this article

Cite this article

Brice, C.A., Dennis, N. Cooling Rate Determination in Additively Manufactured Aluminum Alloy 2219. Metall Mater Trans A 46, 2304–2308 (2015). https://doi.org/10.1007/s11661-015-2775-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-2775-x