Abstract

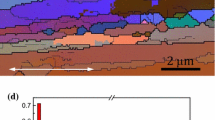

Additions of Sc to an Al-Mg matrix were investigated, paying particular attention to the influence of Al3Sc precipitates and other dispersoids, as well as grain size, on mechanical behavior. Prior studies have shown that Sc significantly increases the strength of coarse-grained Al-Mg alloys. Prompted by these findings, we hypothesized that it would be of fundamental and technological interest to study the behavior of Sc additions to an ultrafine-grained (UFG) microstructure (e.g., 100’s nm). Accordingly, we investigated the microstructural evolution and mechanical behavior of a cryomilled ultrafine grained Al-5Mg-0.4Sc (wt pct) and compared the results to those of an equivalent fine-grained material (FG) produced by powder metallurgy. Experimental materials were consolidated by hot isostatic pressing (HIP’ing) followed by extrusion or dual mode dynamic forging. Under identical processing conditions, UFG materials generate large Al3Sc precipitates with an average diameter of 154 nm and spaced approximately 1 to 3 μm apart, while precipitates in the FG materials have a diameter of 24 nm and are spaced 50 to 200 nm apart. The strengthening mechanisms are calculated for all materials and it is determined that the greatest strengthening contributions for the UFG and FG materials are Mg-O/N dispersion strengthening and precipitate strengthening, respectively.

Similar content being viewed by others

References

O.N. Senkov, D.B. Miracle, S.A. Firstov: Metallic Materials with High Structural Efficiency, p. 3, Springer, Netherlands, Dordrecht, 2004.

Y.V. Milman: High Temp. Mater. Processes., 2006, vol. 25, pp. 1-10.

J. Røyset and N. Ryum: Int. Mater. Rev., 2005, vol. 50, pp. 19-44.

J.N. Fridlyander, N.I. Kolobnev, O.E. Grushko and V.G. Davydov: Mater. Sci. Forum., 1997, vol. 242, p. 249.

G.E. Totten and S.D. MacKenzie: Handbook of aluminum, p. 81-209, M. Dekker, New York, 2003.

E.L. Huskins, B. Cao and K.T. Ramesh: Mater. Sci. Eng., A, 2010, vol. 527, pp. 1292-98.

B. Han, E. Lavernia and F. Mohamed: Metall. Mater. Trans., A 2005, vol. 36, pp. 345-55.

K.E. Knipling, D.N. Seidman and D.C. Dunand: Acta Mater., 2011, vol. 59, pp. 943-54.

F. Fazeli, W.J. Poole and C.W. Sinclair: Acta Mater., 2008, vol. 56, pp. 1909-18.

D.N. Seidman, E.A. Marquis and D.C. Dunand: Acta Mater., 2002, vol. 50, pp. 4021-35.

R.A. Karnesky, L. Meng and D.C. Dunand: Acta Mater., 2007, vol. 55, pp. 1299-1308.

K.L. Kendig and D.B. Miracle: Acta Mater., 2002, vol. 50, pp. 4165-75.

Z. Ahmad: JOM, 2003, vol. 55, pp. 35-39.

O. Wouters: Ph.D. Thesis, University of Groningen, Netherlands, 2006.

E. O. Hall: Proc. Phys. Soc., London, Sect. B, 1951, vol. 64, pp. 747-53.

N.J. Petch: The Journal of the Iron and Steel Institute, 1953, vol. 174, pp. 25-28.

J.C.M. Li: Mechanical properties of nanocrystalline materials, Pan Stanford Publisher, Singapore, 2011.

K. Ma, H. Wen, T. Hu, T.D. Topping, D. Isheim, D.N. Seidman, E.J. Lavernia and J.M. Schoenung: Acta Mater., 2014, vol. 62, pp. 141-155.

C.C. Koch and J. Narayan: MRS Online Proc. Libr., 2000, vol. 634.

G.J. Fan, H. Choo, P.K. Liaw and E.J. Lavernia: Mater. Sci. Eng., A, 2005, vol. 409, pp. 243-48.

M. Khinlay, J.C. Earthman and F.A. Mohamed: Acta Mater., 2012, vol. 60, pp. 5850-57.

C. Xu, Z. Horita and T.G. Langdon: Mater. Sci. Eng., A, 2011, vol. 528, pp. 6059-65.

K. R. Cardoso, D. N. Travessa, W. J. Botta and A. M. Jorge Jr: Mater. Sci. Eng., A, 2011, vol. 528, pp. 5804-11.

C. Xu, M. Furukawa, Z. Horita and T.G. Langdon: Mater. Sci. Eng., A, 2005, vol. 398, pp. 66-76.

O. Sitdikov, T. Sakai, E. Avtokratova, R. Kaibyshev, Y. Kimura and K. Tsuzaki: Mater. Sci. Eng., A, 2007, vol. 444, pp. 18-30.

A. Loucif, R. B. Figueiredo, T. Baudin, F. Brisset and T. G. Langdon, Materials Science and Engineering: A 2010, vol. 527, pp. 4864-4869.

M. Das, G. Das, M. Ghosh, M. Wegner, V. Rajnikant, S. Ghosh Chowdhury and T. K. Pal: Mater. Sci. Eng., A, 2012, vol. 558, pp. 525-32.

A. P. Zhilyaev, K. Oh-ishi, T. G. Langdon and T. R. McNelley: Mater. Sci. Eng., A, 2005, vol. 410–411, pp. 277-80.

E. J. Lavernia, B. Q. Han and J. M. Schoenung: Mater. Sci. Eng., A, 2008, vol. 493, pp. 207-14.

G. Lucadamo, N. Y. C. Yang, C. San Marchi and E. J. Lavernia: Mater. Sci. Eng., A, 2006, vol. 430, pp. 230-41.

D. B. Witkin and E. J. Lavernia: Prog. Mater Sci., 2006, vol. 51, pp. 1-60.

C. Suryanarayana: Prog. Mater Sci., 2001, vol. 46, pp. 1-184.

F. Bensebaa: Nanoparticle technologies: from lab to market. p. 147-54, Elsevier/Academic Press, Amsterdam, 2013.

C. Junsheng, C. Hua, C. Hanbin, Y. Bin, F. Jianzhong and Z. Jishan: J. Univer. Sci. Technol. Beijing, 2007, vol. 14, pp. 523-28.

Y. Li, W. Liu, V. Ortalan, W.F. Li, Z. Zhang, R. Vogt, N.D. Browning, E.J. Lavernia and J.M. Schoenung, Acta Mater., 2010, vol. 58, pp. 1732-40.

R. Vogt, L. Hashemi-Sadraei, Y. Li, Z. Zhang, E.J. Lavernia, J.M. Schoenung and S.E. Mousavi: Mater. Sci. Eng., A, 2012, vol. 43, pp. 747-56.

A. P. Newbery, B. Ahn, P. Pao, S. R. Nutt and E. J. Lavernia, AMR Advanced Materials Research 2007, vol. 29-30, pp. 21-29.

M.A. Meyers and K.K. Chawla: Mechanical behavior of materials, p. 369-99, 558-91, Cambridge University Press, Cambridge, 2009.

T.H. Courtney: Mechanical behavior of materials, p. 1-210, Waveland, Illinois, 2000.

I.E. Foley and J.C. Anderson: Surf. Interface Anal., 2001, vol. 31, pp. 599-608.

A.P. Newbery, B. Ahn, R.W. Hayes, P.S. Pao, S.R. Nutt and E.J. Lavernia: Mater. Sci. Eng., A, 2008, vol. 39, pp. 2193-2205.

T.D. Topping. Ph.D. Dissertation, Materials Science and Engineering, University of California, Davis, 2012.

T.D. Topping, S.R. Nutt and E.J. Lavernia: Mater. Sci. Eng., A, 2012, vol. 43, pp. 505-19.

A.P. Newbery, B. Ahn, T.D. Topping, P.S. Pao, S.R. Nutt and E.J. Lavernia: J. Mater. Process. Technol., 2008, vol. 203, pp. 37-45.

L. Shaw, H. Luo, J. Villegas, and D. Miracle: Scripta Mater., 2004, vol. 50, pp. 921-25.

E.A. Olevsky, J. Ma, J.C. LaSalvia and M.A. Meyers: Acta Mater., 2007, vol. 55, pp. 1351-66.

F. Tang, H. Meeks, J.E. Spowart, T. Gnaeupel-Herold, H. Prask and I.E. Anderson: Mater. Sci. Eng. A, 2004, vol. 386.

R. Z. Valiev, I. V. Alexandrov, N. A. Enikeev, M. Yu Murashkin and I. P. Semenova: Rev. Adv. Mater. Sci., 2010, vol. 25, pp. 1-10.

B.A. Parker, Z.F. Zhou and P. Nolle: J. Mater. Sci,. 1995, vol. 30, pp. 452-58.

J. Royset: Metall. Sci. Technol., 2007, vol. 25, pp. 11-21.

S. J. L. Kang: Sintering : densification, grain growth, and microstructure. Elsevier Butterworth-Heinemann, Amsterdam, p. 37-70, 2005).

X. Wang and F. Ding: Adv. Mater. Res., 2011, vol. 146-147, pp. 1094-1101.

B. Zheng, Y. Lin, Y. Zhou and E.J. Lavernia: Mater. Sci. Eng., B, 2009, vol. 40, pp. 995-1004.

B. Zheng, L. Yaojun, Y. Zhou and E.J. Lavernia: Mater. Sci. Eng., B, 2009, vol. 40, pp. 768-78.

Z. Zhang, S. Dallek, R. Vogt, Y. Li, T. Topping, Y. Zhou, J. Schoenung and E. Lavernia: Metall. Mater. Trans. A, 2010, vol. 41, pp. 532-41.

O.C. Hellman, J.A. Vandenbroucke, J. Rusing, D. Isheim and D.N. Seidman: Microsc. Microanal., 2000, vol. 6, pp. 437-44.

H. Wen, T.D. Topping, D. Isheim, D.N. Seidman and E.J. Lavernia: Acta Mater., 2013, vol. 61, pp. 2769-82.

ASTM, “Standard Test Methods for Tension Testing of Metallic Materials,” 2008.

K. Kanaya and S. Okayama: J. Phys., D, 1972, vol. 5, pp. 43-58.

E.A. Marquis and D.N. Seidman: Acta Mater., 2005, vol. 53, pp. 4259-68.

M.F. Ashby and L.M. Brown: Philos. Mag., 1963, vol. 8, pp. 1083-1103.

L.S. Toropova: Advanced aluminum alloys containing scandium : structure and properties, Gordon and Breach Science Publishers, Amsterdam, 1998: 20–155.

M.E. Drits, Y.G. Bykov and L.S. Toropova: Met. Sci. Heat Treat., 1985, vol. 27, pp. 309-12.

S. Iwamura, M. Nakayama and Y. Miura: Mater. Sci. Forum, 2002, vol. 396/402, pp. 1151-56.

G. Sha and A. Cerezo: Acta Mater., 2004, vol. 52, pp. 4503-16.

M. Dumont, W. Lefebvre, B. Doisneau-Cottignies and A. Deschamps: Acta Mater., 2005, vol. 53, pp. 2881-92.

T. Pettersen, B. Holmedal and E. Nes: Metall. Mater. Trans. A, 2003, vol. 34, 2737-44.

K. Ma and J.M. Schoenung: Philos. Mag. Lett., 2010, vol. 90, pp. 739-51.

K. Ma, J.M. Schoenung and E.J. Lavernia: Adv. Eng. Mater., 2012, vol. 14, pp. 77-84.

V. L. Tellkamp, E.J. Lavernia and A. Melmed: Metall. Mater. Trans., A, 2001, vol. 32, pp. 2335-43.

J.S. Vetrano, S.M. Bruemmer, L.M. Pawlowski and I.M. Robertson: Mater. Sci. Eng., A, 1997, vol. 238, pp. 101-07.

M. Ferry, N.E. Hamilton and F.J. Humphreys: Acta Mater., 2005, vol. 53, pp. 1097-1109.

H. J. Fecht: Nanostruct. Mater. 1995, vol. 6, pp. 33-42.

F. Zhou, R. Rodriguez, and E.J. Lavernia: Mater. Sci. Forum, 2002, vol. 386/388, pp. 409-14.

C. Goujon, P. Goeuriot, M. Chedru, J. Vicens, J.L. Chermant, F. Bernard, J.C. Niepce, P. Verdier and Y. Laurent: Powder Technol., 1999, vol. 105, pp. 328-36.

L. Jiang, J.K. Li, P.M. Cheng, G. Liu, R.H. Wang, B.A. Chen, J.Y. Zhang, J. Sun, M.X. Yang, and G. Yang: Sci. Rep., 2014, vol. 4.

T. Hu, K. Ma, T. D. Topping, J. M. Schoenung and E. J. Lavernia: Acta Mater., 2013, vol. 61, pp. 2163-78.

G.M. Novotny and A.J. Ardell: Mater. Sci. Eng., A, 2001, vol. 318, pp. 144-54.

M.J. Jones and F.J. Humphreys: Acta Mater., 2003, vol. 51, pp. 2149-59.

M. Nakayama, A. Furuta, Y. Miura: Nippon Kinzoku Gakkaishi, 1995, vol. 59, p. 487.

E.A. Marquis and D. N. Seidman: Acta Mater., 2001, vol. 49, pp. 1909-19.

J.D. Robson, M.J. Jones and P.B. Prangnell: Acta Mater., 2003, vol. 51, pp. 1453-68.

J.W. Martin, R.D. Doherty and B. Cantor: Stability of microstructure in metallic systems, p. 219-366, Cambridge University Press, Cambridge, 1997.

I. M. Lifshitz and V.V. Slyozov: J. Phys. Chem. Solids, 1961, vol. 19, pp. 35-50.

R.W. Balluffi, A.M. Samuel, C.W. Carter and R.A. Kemper: Kinetics of materials, p. 363-81, J. Wiley & Sons, Hoboken, N.J., 2005.

C. Watanabe, D. Watanabe, R. Tanii and R. Monzen: Philos. Mag. Lett., 2010, vol. 90, pp. 103-11.

E. Kozeschnik, J. Svoboda, R. Radis and F.D. Fischer: Modell. Simul. Mater. Sci. Eng., 2010, vol. 18, pp. 1-19.

T.D. Topping and E.J. Lavernia: 13th International Conference on Aluminum Alloys, p. 959-69, John Wiley & Sons, Inc., 2012.

J. Chen, L. Zhen, L. Fan, S. Yang, S. Dai and W. Shao: Trans. Nonferrous Met. Soc. China, 2009, vol. 19, pp. 1071-75.

B.Q. Han, F.A. Mohamed, C. Bampton and E.J. Lavernia: Mater. Res. Soc. Symp. Pro., 2004, vol. 791, pp. 11-16.

B. Raeisinia, C.W. Sinclair, W.J. Poole and C.N. Tomé: Modell. Simul. Mater. Sci. Eng., 2008, vol. 16, pp. 1-15.

O. Randle and V. Engler: Introduction to texture analysis : macrotexture, microtexture, and orientation mapping, p. 3, CRC Press, Boca Raton, 2010.

Y. Li, T.D. Topping, Z. Zhang, R.G. Vogt, J.M. Schoenung and E.J. Lavernia: Microsc. Microanal., 2012, vol. 18, pp. 1902-03.

N. Hansen and B. Ralph: Acta Metall., 1986, vol. 34, pp. 1955-62.

M.E. Drits, L.S. Toropova and Y.G. Bykov: Met. Sci. Heat Treat., 1983, vol. 25, pp. 550-54.

A.J. Ardell: Metall. Trans. A, 1985, vol. 16, pp. 2131-65.

M.S. Kaiser, S. Datta, A. Roychowdhury and M.K. Banerjee: Mater. Manuf. Processes, 2008, 23: 74-81.

M.S. Kaiser, S. Datta, A. Roychowdhury and M.K. Banerjee: J. Mater. Eng. Perform., 2008, vol. 17, pp. 902-07.

C. Booth-Morrison, D.C. Dunand and D.N. Seidman: Acta Mater., 2011, vol. 59, pp. 7029-42.

B. Clausen: Ph.D. Thesis, Department of Solid Mechanics Dcamm, Technical University of Denmark, Lyngby, 1997.

J. W. Hutchinson: Proc. R. Soc. London Ser. A, 1970, vol. 319, pp. 247-72.

R.W. Hyland and R.C. Stiffler: Scripta Metall. Mater., 1991, vol. 25, pp. 473-77.

A.S. Argon and E. Orowan: Physics of strength and plasticity, M.I.T. Press, Cambridge, 1969, p. 189.

E.A. Marquis, D.N. Seidman and D.C. Dunand: Acta Mater., 2003, vol. 51, pp. 4751-60.

O. Madelung, U. Rössler, and M. Schulz: The Landolt-Bornstein Database, vol. 111V/17B-22A-41B, 2013.

D. Chung: Philos. Mag., 1963, vol. 8, pp. 833-41.

T.J. Van Daam and C. Bampton: US Patent, vol. Patent No. US 7,344,675 B2, 2008.

K.T. Ramesh: Nanomaterials: mechanics and mechanisms, (Springer, Dordrecht, 2009).

R. W. Cahn and P. Haasen: Physical metallurgy, (North-Holland Physics, Amsterdam, 1996).

Ø. Ryen, B. Holmedal, O. Nijs, E. Nes, E. Sjölander and H. Ekström: Metall. Mater. Trans., A, 2006, vol. 37, pp. 1999-2006.

G.K. Williamson and W. H. Hall: Acta Metall., 1953, vol. 1, pp. 22-31.

H. Wen, R.K. Islamgaliev, K.M. Nesterov, R.Z. Valiev, E.J. Lavernia: Philos. Mag. Lett., 2013, vol. 93, pp. 481-89.

J.R. Davis Associates and ASM International Handbook Committee: Aluminum and Aluminum Alloys, ASM International, Materials Park, OH, 1993.

E.A. Marquis, D.N. Seidman, M. Asta, C. Woodward and V. Ozolins: Phys. Rev. Lett., 2003, vol. 91, pp. 1-4.

N. Kumar and R. S. Mishra: Mater. Sci. Eng., A, 2013, vol. 580, pp. 175-83.

Acknowledgments

The authors would like to acknowledge and express their appreciation for the support provided by the Office of Naval Research (Contract No. N00014-12-C-0241 and Grant No. ONR N00014-12-1-0237) and the program managers, Mr. Rodney Peterson, Dr. William Golumbfskie, and Dr. Lawrence Kabacoff. In addition, Prof. David N. Seidman and Dr. Dieter Isheim are acknowledged for providing access to atom probe and other facilities at Northwestern University Center for Atom Probe Tomography (NUCAPT).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted October 9, 2013.

Rights and permissions

About this article

Cite this article

Harrell, T.J., Topping, T.D., Wen, H. et al. Microstructure and Strengthening Mechanisms in an Ultrafine Grained Al-Mg-Sc Alloy Produced by Powder Metallurgy. Metall Mater Trans A 45, 6329–6343 (2014). https://doi.org/10.1007/s11661-014-2569-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-014-2569-6