Abstract

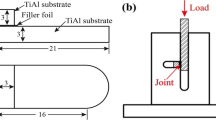

Low melting point Zr-based filler metals with melting point depressants (MPDs) such as Cu and Ni elements are used for titanium brazing. However, the phase transition of the filler metals in the titanium joint needs to be explained, since the main element of Zr in the filler metals differs from that of the parent titanium alloys. In addition, since the MPDs easily form brittle intermetallics, that deteriorate joint properties, the phase evolution they cause needs to be studied. Zr-based filler metals having Cu content from 0 to 12 at. pct and Ni content from 12 to 24 at. pct with a melting temperature range of 1062 K to 1082 K (789 °C to 809 °C) were wetting-tested on a titanium plate to investigate the phase transformation and evolution at the interface between the titanium plate and the filler metals. In the interface, the alloys system with Zr, Zr2Ni, and (Ti,Zr)2Ni phases was easily changed to a Ti-based alloy system with Ti, Ti2Ni, and (Ti,Zr)2Ni phases, by the local melting of parent titanium. The dissolution depths of the parent metal were increased with increasing Ni content in the filler metals because Ni has a faster diffusion rate than Cu. Instead, slow diffusion of Cu into titanium substrate leads to the accumulation of Cu at the molten zone of the interface, which could form undesirable Ti x Cu y intermetallics. This study confirmed that Zr-based filler metals are compatible with the parent titanium metal with the minimum content of MPDs.

Similar content being viewed by others

References

A. Shapiro and A. Rabinkin: Welding J., 2003, vol. 82(10), pp. 36-43.

O. Botstein and A. Rabinkin: Mater. Sci. Eng. A, 1994,vol. 188, pp. 305-315.

O. Botstein, A. Schwarzman, and A. Rabinkin: Mater. Sci. Eng. A, 1996, vol. 206, pp. 14-23.

T. Onzawa, A. Suzumura, and M.W. Ko: Welding J., 1990, vol. 69(12), pp. S462-S467.

E. Chang and C.H. Chen: J. Mater. Eng. Perform., 1997, vol. 6, pp. 792-796.

E. Chang and C.H. Chen: J. Mater. Eng. Perform., 1997, vol. 6, pp. 797-803.

D.M. Lee, J.H. Sun, D.H. Kang, S.Y. Shin, and C.H. Lee: J. Mater. Res., 2009, vol. 24(7), pp. 2338-2345.

J.H. Sun, D.M. Lee, C.H. Lee, J.W. Hong, and S.Y. Shin: J. Mater. Res., 2010, vol. 25(2), pp. 296-302.

P. Villars, A. Prince, and H. Okamoto: Handbook of Ternary Metal Phase Diagrams, ASM International, Materials Park, 1995.

N. Eustathopoulos, M.G. Nigohlas, and B. Drevei: Wettability at high temperatures, Pergamon, UK, 1999.

W.Y. Kim, B.H. Jung, and S.Y. Lee: J. KWS, 1995, vol. 13 (3), pp. 106–115.

M.M. Schwartz: Brazing, 2nd ed., ASM international, Materials Park, 2003.

T.B. Massalski: Binary Alloy Phase Diagrams, ASM International, Materials Park, 1990.

R.A. Perez, H. Nakajima, and F. Dyment: Mater. Tran., 2003, vol. 44(1), pp. 2-13.

R.R. Wells: Welding J., 1976, vol. 55(1), pp. S20-S27.

M.M. Schwartz: Welding J., 1978, vol. 57(9), pp. 35-38.

X. Huang and N.L. Richards: Welding J., 2004, vol. 83(3), pp. 73S-81S.

K.J. Doherty, J.R. Tice, S.I. Szewczyk, and G.A. Gilde: Welding J., 2007, vol. 86(9), pp. 41-46.

D.G. Howden and R.W. Monroe: Welding J., 1972, vol. 51(1), pp. 31-36.

K. Matsu, Y. Miyazawa, Y. Nishi, and T. Ariga T: Proceedings of the Brazing and Soldering, 2006, pp. 307–09.

Acknowledgments

This work was supported by the National Research Foundation of Korea Grant funded by the Korean Government [NRF-2009-352-D00123].

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 23, 2013.

Rights and permissions

About this article

Cite this article

Lee, D., Sun, J., Kang, D. et al. Microstructural Evolution of the Interface Between Pure Titanium and Low Melting Point Zr-Ti-Ni(Cu) Filler Metals. Metall Mater Trans A 45, 5914–5922 (2014). https://doi.org/10.1007/s11661-014-2561-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-014-2561-1