Abstract

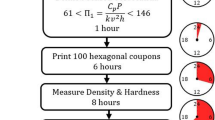

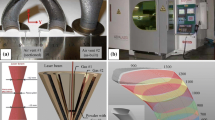

Additive manufacturing (AM) technology provides unique opportunities for producing net-shape geometries at the macroscale through microscale processing. This level of control presents inherent trade-offs necessitating the establishment of quality controls aimed at minimizing undesirable properties, such as porosity and residual stresses. Here, we perform a parametric study into the effects of laser scanning pattern, power, speed, and build direction in powder bed fusion AM on residual stress. In an effort to better understand the factors influencing macroscale residual stresses, a destructive surface residual stress measurement technique (digital image correlation in conjunction with build plate removal and sectioning) has been coupled with a nondestructive volumetric evaluation method (i.e., neutron diffraction). Good agreement between the two measurement techniques is observed. Furthermore, a reduction in residual stress is obtained by decreasing scan island size, increasing island to wall rotation to 45 deg, and increasing applied energy per unit length (laser power/speed). Neutron diffraction measurements reveal that, while in-plane residual stresses are affected by scan island rotation, axial residual stresses are unchanged. We attribute this in-plane behavior to misalignment between the greatest thermal stresses (scan direction) and largest part dimension.

Similar content being viewed by others

References

I. Gibson, D.W. Rosen, B. Stucker: Additive manufacturing technologies: Rapid prototyping to direct digital manufacturing, Springer, New York, NY, 2010.

S.H. Huang, P. Liu, A. Mokasdar, L. Hou: International Journal of Advanced Manufacturing Technology, 2013, vol. 67, pp. 1191-1203.

D.D. Gu, W. Meiners, K. Wissenbach, R. Poprawe: International Materials Reviews, 2012, vol 57, pp. 133-164.

R. Felzmann, S. Gruber, G. Mitteramskogler, P. Tesavibul, A.R. Boccaccini, R. Liska, J. Stampfl: Advanced Engineering Materials, 2012, vol. 14, pp. 1052-1058.

N. Travitzky, A. Bonet, B. Dermeik, T. Fey, I. Filbert-Demut, L. Schlier, T. Schlordt, P. Greil: Advanced Engineering Materials, 2014, DOI: 10.1002/adem.201400097.

P. Mercelis and J.-P. Kruth: Rapid Prototyping Journal,2006, vol. 12, pp. 254-265.

C.R. Knowles, T.H. Becker, R.B. Tait: South African Journal of Industrial Engineering, 2012, vol. 23, pp. 119-129.

M.F. Zaeh, G. Branner: Prod. Eng. Res. Devel., 2010, vol. 4, pp. 35-45.

J.P. Kruth, J. Deckers, E. Yasa, R. Wauthlé: Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2012, vol. 226, pp. 980-991.

E. Yasa: Dissertation, Katholieke Universiteit Leuven, Belgium, 2011.

N.W. Klingbeil, J.L. Beuth, R.K. Chin, C.H. Amon: International Journal of Mechanical Sciences, 2002, vol. 44, pp. 57-77.

P. Aggarangsi and J.L. Beuth: Proc. Annu. Int. Solid Freeform Fabr. Sympos., Austin, Texas, 2006, pp. 709–20.

A. Vasinota, J.L. Beuth, M.L. Griffith: ASME Journal of Manufacturing Science and Engineering, 2007, vol. 129, pp. 101-109.

M. Shiomi, K. Osakada, K. Nakamura, T. Yamashita, F. Abe: CIRP Annals - Manufacturing Technology, 2004, vol. 53, pp. 195-198.

V. Hauk: Structural and residual stress analysis by nondestructive methods, Elsevier Science B.V. Amsterdam, The Netherlands, 1997.

P.J. Withers, H.K.D.H. Bhadeshia: Materials Science and Technology, 2001, vol. 17, pp. 355-365.

I.C. Noyan, T.C. Huang, B.R. York: Critical Reviews in Solid State and Materials Sciences, 1995, vol. 20, pp. 125-177.

D.W. Brown, T.M. Holden, B. Clausen, M.B. Prime, T.A. Sisneros, H. Swensen, J. Vaja: Acta Materialia, 2011, vol. 59, pp. 864-873.

M.E. Fitzpatrick, A. Lodini: Analysis of Residual Stress by Diffraction Using Neutron and Synchrotron Radiation. Taylor & Francis, London, 2003.

D.I. Crecraft: Journal of Sound and Vibration, 1967, vol. 5, pp. 173-192.

D.D.L. Chung: Thermochemica Acta, 2000, vol. 364, pp. 121-132.

E.S. Gorkunov, S.M. Zadvorkin, and L.S. Goruleva: 18th World Conference for Nondestructive Testing, Durban, South Africa, 16–20 April, 2012.

V. Sergo, G. Pezzotti, O. Sbaizero, T. Nishida: Acta Materialia, 1998, vol. 46, pp.1701-10.

J.W. Ager III, M.D. Drory: Physical Review B, 1993, vol. 48, pp. 2601-2607.

K. Kusaka, T. Hanabusa, M. Nishida, F. Inoko: Thin Solid Films, 1996, vol. 290–291, pp. 248-253.

T. Kannengiesser, A. Kromm, M. Rethmeier, J. Gibmeier, C. Genzel: Advances in X-ray Analysis, 2009, vol. 52, pp. 755-762.

Y. Watanabe, M. Nishida, T. Hanabusa: Advances in X-ray Analysis, 2009, vol. 52, pp. 271-278.

ASTM Standard E837 REV A: Standard Test Method for Determining Residual Stresses by the Hole-Drilling Strain-Gage Method, ASTM International, West Conshohocken, PA, 2013.

M.B. Prime: Journal of Engineering Materials and Technology, 2000, vol. 123, pp. 162-168.

M.B. Prime: Applied Mechanics Reviews, 1999, vol. 52, pp. 75-96.

D.V. Nelson, A. Makino, T. Schmidt: Experimental Mechanics, 2006, vol. 46, pp. 31-38.

J.D. Lord, D. Penn, P. Whitehead: Applied Mechanics and Materials, 2008, vol. 13-14, pp. 65-73.

J. Gao, H. Shang: Applied Optics, 2009, vol. 48, pp. 1371-1381.

A. Baldi: Experimental Mechanics, 2013, doi: 10.1007/s11340-013-9814-6.

J. Zhu, H. Xie, Z. Hu, P. Chen, Q. Zhang: Surface & Coatings Technology, 2011, vol. 206, pp. 1396-1402.

N. Daynes, G. Horne, P.J. Heard, D.Z.L. Hodgson, A. Shterenlikht: Advances in X-ray Analysis, 2009, vol. 52: pp. 651-658.

A. M. Korsunsky, M. Sebastiani, E. Bemporad: Surface & Coatings Technology, 2010, vol. 205, pp. 2393-2403.

Y.S. Yang, J.G. Bae, C.G. Park: Journal of Physics: Conference Series, 2008, vol. 100, pp. 012018.

L. Bingleman and G.S. Schaker: Proceedings of the SEM Annual Conference, June 7-10, 2010, Indianapolis, USA.

J. Zhang: Optical Engineering, 1998, vol. 37, pp. 2402-2409.

O. Sedivy, C. Krempaszky, and S. Holy: Aust. Congr. Appl. Mech., Brisbane, Australia, December 10–12, 2007.

J. Zhang, W.C. Fok, and T.C. Chong: Proc. SPIE 2921, Int. Conf. Exp. Mech. Adv. Appl., 1997, pp. 584–91.

S. Suresh, A.E. Giannakopoulos: Acta Materialia, 1998, vol. 46, pp. 5575-5567.

B. Vrancken, R. Wauthlé, J.-P. Kruth, and J. Van Humbeeck: Proc. Solid Freeform Fabr. Sympos., Austin, Texas, Aug. 12-14, 2013, pp. 393–407.

C. Kamath, B. El-dasher, G.F. Gallegos, W.E. King, R. Lee, and A. Sisto: Int. J. Adv. Manuf. Technol., 2014, vol. 74, pp. 65–78.

L. Thijs, M.L. Montero Sistiaga, R. Wauthle, Q.G. Xie, J.-P. Kruth, J. V. Humbeeck: Acta Materialia, 2013, vol. 61, pp. 4657-4668.

T. Niendorf, S. Leuders, A. Riemer, H.A. Richard, T. Tröster, D. Schwarze: Metallurgical and Materials Transactions B, 2013, vol. 44B, pp. 794-796.

J.A. Choren, S.M. Heinrich, M.B. Silver-Thorn: Journal of Materials Science, 2013, vol. 48, pp. 5103-5112.

H. Gu, H. Gong, D. Pal, K. Rafi, T. Starr, and B. Stucker: Twenty Forth Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, August 12–14, 2013.

D.B. Hann, J. Iammi, J. Folkes: J. Phys. D: Appl. Phys., 2011, vol. 44, pp. 445401.

T.W. Eagar, N.S. Tsai: Welding Journal, 1983, vol. 62, pp. S346-S355.

R. Rai, J.W. Elmer, T.A. Palmer, T. DebRoy: J. Phys. D: Appl. Phys., 2007, vol. 40, pp. 5733-5766.

P. Bleys, J.-P. Kruth, B. Lauwers, B. Schacht, V. Balasubramanian, L. Froyen, J.V. Humbeek: Advanced Engineering Materials, 2006, vol. 8, pp. 15-25.

L. Wang, S.D. Felicelli, P. Pratt: Materials Science and Engineering A, 2008, vol. 496, pp. 234-241.

Acknowledgments

This work was performed under the auspices of the U.S. Department of Energy by Lawrence Livermore National Laboratory under Contract DE-AC52-07NA27344. This work was funded by the Laboratory Directed Research and Development Program at LLNL under project tracking code 13-SI-002 and has been assigned the document release ID #LLNL-JRNL-654740.

The authors would like to acknowledge the guidance and expertise of Ms. Mary M. LeBlanc (LLNL) in mechanical characterization techniques and digital image correlation methodology. Dr. Bjørn Clausen and Dr. Thomas A. Sisneros (LANL, Lujan Center) are recognized for their time and expertise in neutron diffraction. The authors also recognize Dr. Bassem el-Dasher, Dr. Robert Ferencz, and Dr. Neil Hodge (LLNL) for their guidance in planning these experiments—and, in particular, Dr. Neil Hodge for melt pool geometry predictive capabilities, as well as Dr. Chandrika Kamath (LLNL) for process optimization expertise and Dr. John Elmer (LLNL) for his advice and expertise. Mr. Gregory J. Larsen and Mr. Paul Alexander are recognized for their drafting efforts and processing expertise, respectively. Dr. Karl Fisher provided the RUS measurements of elastic modulus used in this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 8, 2014.

Rights and permissions

About this article

Cite this article

Wu, A.S., Brown, D.W., Kumar, M. et al. An Experimental Investigation into Additive Manufacturing-Induced Residual Stresses in 316L Stainless Steel. Metall Mater Trans A 45, 6260–6270 (2014). https://doi.org/10.1007/s11661-014-2549-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-014-2549-x