Abstract

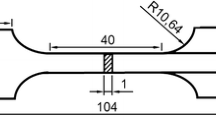

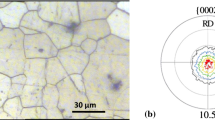

Seamless tubes of AZ31, AZ31 + 0.4, and 0.8 wt pctSr were extruded at elevated temperatures. By compressing pure copper inserts inside the tubes, the extruded tubes were expanded at room and elevated temperatures [373 K and 473 K (100 °C and 200 °C)]. Microstructural examinations reveal the formation of twining in the as-extruded and expanded tubes. The amount of twinning decreased with increasing level of Sr in the expanded microstructures as a result of grain refinement and of decreasing Al in solution that facilitates dislocation motion. During expansion at room temperature, AZ31 shows higher elongation and lower strength than the alloys containing Sr. At 473 K (200 °C), compared to the lower temperatures, the Sr containing alloys exhibit lower flow stress and no fracture in the strain range investigated (40 pct reduction in cylinder height). The textures of the extruded alloys contain two main components named as RD (c-axis parallel to the radial direction) and HD (c-axis parallel to the hoop direction) based on their orientation with the sample coordinates. During expansion, extension twinning in the HD grains reorients the lattice to strengthen the RD and form a new ED (c-axis parallel to the extrusion direction) component. By increasing the temperature or level of Sr, the ED component is weakened due to the decrease in twinning. During expansion, the RD grains undergo contraction and double twining which reduce the overall texture strength.

Similar content being viewed by others

References

Q. Jin, S.-Y. Shim, S.-G. Lim, “Correlation of microstructural evolution and formation of basal texture in a coarse grained Mg–Al alloy during hot rolling,” Scripta Materialia 55 (2006) 843–846.

J. Bohlen, S.B. Yi, J. Swiostek, D. Letzig, H.G. Brokmeier, K.U. Kainer, “Microstructure and texture development during hydrostatic extrusion of magnesium alloy AZ31,” Scripta Materialia Vol 53, Issue 2, (2005) 259-264.

S.S. Park, B.S. You, D.J. Yoon, “Effect of the extrusion conditions on the texture and mechanical properties of indirect-extruded Mg–3Al–1Zn alloy,” Journal of Materials Processing Technology, Vol 209, Issues 18-19 (2009) 5940-5943.

Y. Chen, Q. Wang, J. Peng, C. Zhai, W. Ding, “Effects of extrusion ratio on the microstructure and mechanical properties of AZ31 Mg alloy,” Journal of Materials Processing Technology, Vol 182, Issues 1-3 (2007) 281-285.

M. Shahzad, L. Wagner, “Influence of extrusion parameters on microstructure and texture developments, and their effects on mechanical properties of the magnesium alloy AZ80,” Materials Science and Engineering: A, Vol 506, Issues 1-2 (2009) 141-147T.

H.J. McQueen, M. Pekguleryuz, Hot Workability of Magnesium Alloys, Magnesium Alloys and their Applications, Garmisch Partenkirchen, Germany, 1992, pp. 101–108.

N. Stanford, M.R. Barnett, “The origin of “rare earth” texture development in extruded Mg-based alloys and its effect on tensile ductility,” Materials Science and Engineering A, Volume 496, Issues 1–2 (2008) 399-408.

N. Stanford, “Micro-alloying Mg with Y, Ce, Gd and La for texture modification—A comparative study,” Materials Science and Engineering A, Vol 527, Issues 10-11 (2010) 2669-2677.

L.W.F. Mackenzie, B. Davis, F.J. Humphreys, G.W. Lorimer, “The deformation, recrystallization and texture of three magnesium alloy extrusions,” Materials Science and Technology, Vol 23, No 10 (2007) 1173-1180.

L.W.F. Mackenzie, M.O. Pekguleryuz, “The recrystallization and texture of magnesium-zinc-cerium alloys,” Scripta Materialia, Vol 59, No 6 (2008) 665-668.

J.D. Robson, D.T. Henry, B. Davis, “Particle effects on recrystallization in magnesium–manganese alloys: Particle-stimulated nucleation,” Acta Materialia, 57, (2009) 2739-2747.

O. Anopuo, Y. Huang, H. Dieringa, N. Hort, K.U. Kainer, A.K. Khan, “Mechanical Properties and Corrosion Performance of AZ-Mg Alloy Modified with Ca and Sr,” SAE Int. J. Mater. Manuf. 1(1), (2009) 103-110.

A. Sadeghi, M. Pekguleryuz, “Precipitation of Mg-3%Al-1%Zn-(0.01-1) wt%Sr Alloys during solidification,” Journal of Materials Research, Journal of Materials Research, Volume 26, Issue 07 (2011) 896 – 903.

A. Sadeghi, M. Pekguleryuz, “Microstructure, mechanical properties and texture evolution of AZ31 alloy containing trace levels of strontium,” Materials Characterization, Volume 62, Issue 8, (2011) 742-750.

A. Sadeghi, M. Pekguleryuz, “Recrystallization and Texture Evolution of Mg-3%Al-1%Zn-(0.4 -0.8) %Sr Alloys during Extrusion,” Materials Science and Engineering A, Materials Science and Engineering: A, Volume 528, Issue 3 (2011) 1678-1685.

A. Sadeghi, M. Hoseini, M. Pekguleryuz, “Effect of Sr addition on texture evolution of Mg–3Al–1Zn (AZ31) alloy during extrusion,” Materials Science and Engineering: A, Materials Science and Engineering: A, Volume 528, Issues 7-8 (2011) 3096-3104.

A. Sadeghi, S. Shook, and M. Pekguleryuz, Mat. Sci. Eng. A, 528(25): 7529–36, 2011.

RJ Cheng, AT Tang, MB Yang, FS Pan, Mater. Sci. Forum 546–549: 183–86, 2007.

A. Sadeghi, M. Pekguleryuz, “Tube Extrusion of AZ31 Alloy with Sr Additions,” Materials Science and Engineering: A, Volume 544, 15 May 2012, Pages 70–79.

F.J. Humphreys, M. Hatherly, “Recrystallization and related annealing phenomena,” Pergamon Press, Oxford (1996).

E. Martin, J.J. Jonas, Acta Mater. 58:4253–66, 2010.

H.K. Lin, J.C. Huanga, T.G. Langdon, “Relationship between texture and low temperature superplasticity in an extruded AZ31 Mg alloy processed by ECAP,” Materials Science and Engineering A, 402 (2005) 250–257.

S.R. Agnew, P. Mehrotra, T.M. Lillo, G.M. Stoica, P.K. Liawc, “Crystallographic texture evolution of three wrought magnesium alloys during equal channel angular extrusion,” Materials Science and Engineering A, 408 (2005) 72–78.

S.R. Agnew, P. Mehrotra, T.M. Lillo, G.M. Stoica, P.K. Liaw, “Texture evolution of five wrought magnesium alloys during route A equal channel angular extrusion: Experiments and simulations,” Acta Materialia 53 (2005) 3135–3146.

S.X. Ding, W.T. Lee, C.P. Chang, L.W. Chang and P.W. Kao, “Improvement of strength of magnesium alloy processed by equal channel angular extrusion,” Scripta Materialia 59 (2008) 1006–1009.

E. Bertrand, P. Castany, I. Péron, T. Gloriant, Scripta Mater. 64:1110–1113, 2011.

É. Martin, L. Capolungo, L. Jiang, J.J. Jonas, Acta Materialia 58: 3970–3983, 2010.

M.R. Barnett, Z. Keshavarz, A.G. Beer and X. Ma: Non-Schmid Behaviour of Secondary Twinning in a Polycrystalline Magnesium Alloy, Acta Materialia, Vol. 56, No. 1, 2008, 5-15.

M. H. Yoo, Metall. Trans. A, 12A:409–18, 1981.

A. Becerra and M. Pekguleryuz, J. Mater. Res., 23(12):3379–86 (2008).

G.V. Raynor: The Physical Metallurgy of Magnesium and Its Alloys (Pergamon Press, New York, 1959).

J.S. Park, Y.W. Chang, Adv. Mater. Res. 26–28, 95, 2007.

M. H. Yoo; J. K. Lee, “Deformation twinning in h.c.p. metals and alloys,” Philosophical Magazine A, 63: 5, 987 — 1000 (1991).

M. Pekguleryuz, M. Celikin, M. Hoseini, A. Becerra, and L. Mackenziec, J. Alloys Compd., in press.

Acknowledgments

This study was carried out under a Strategic project grant from Natural Sciences and Engineering Research Council (NSERC) of Canada. The authors acknowledge Applied Magnesium (formerly Timminco) for the industrial support and for providing the raw materials and master alloy. One of the authors, A. Sadeghi gratefully acknowledges the financial support of McGill University through MEDA (McGill Engineering Doctoral Award) Program.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 27, 2012.

Rights and permissions

About this article

Cite this article

Sadeghi, A., Martin, É. & Pekguleryuz, M. Texture Evolution and Twinning During the Expansion of Hot Extruded AZ31 + Sr Seamless Tubes. Metall Mater Trans A 45, 6304–6316 (2014). https://doi.org/10.1007/s11661-014-2546-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-014-2546-0