Abstract

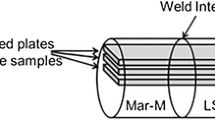

The solid state inertia friction welding (IFW) process was used for the first time to join two dissimilar Ni-based superalloys, LSHR, a powder metallurgy alloy, and Mar-M247, a directionally solidified alloy. Extensive studies of the microstructure, phase composition, re-distribution of the alloying elements between the welded alloys, microhardness, and welding defects were conducted at different distances from the weld interface, and the results were correlated with the loading and friction conditions during IFW. Possible reasons leading to the formation of the welding defects were discussed and directions for the further improvement of the quality of the IFW of these two dissimilar alloys were outlined.

Similar content being viewed by others

References

J.H. Perepezko, Science, 326, No. 5956 (2009) 1068-1069.

D.M. Dimiduk, J.H. Perepezko, MRS Bull 28 (2003) 639–645.

R.C. Reed, The Superalloys: Fundamentals and Applications, Cambridge University Press, Cambridge, UK, 2006.

W.S. Walston, J.C. Schaeffer, W.H. Murphy, in Superalloys 1996, TMS, Warrendale, PA, 1996, pp. 9–18.

RV Miner, TP Gabb, J Gayda, KJ Hemker, Metall. Trans. A, 17A (1986) 507-512.

D. Siebörger, H. Knake, U. Glatzel, Mater. Sci. Eng. A 268 (2001) 26-33.

S. Walston, A. Cetel, R. MacKay, K. O’Hara, D. Duhl, and R. Dreshfield: Superalloys 2004, TMS, Warrendale, PA, 2004, pp. 15–24.

S. Wlodek, M. Kelly, D. Alden, Superalloys-1996, TMS, Materials Park, PA, 1996, 129–136.

J. Hurst, Materials and Structures Research for Gas Turbine Applications Within the NASA Subsonic Fixed Wing Project, NASA/TM-2011-216747, NASA Glenn Research Center, Cleveland, OH, 2011.

J.N. DuPont, J.C. Lippold, S.D. Kiser, Welding Metallurgy and Weldability of Nickel-Base Alloys, John Wiley & Sons, Hoboken, New Jersey, 2009.

R. Kovacivic ed.: Welding Processes, InTech, Rijeka, Croatia, 2012.

C.T. Sims,W.C. Hagel, The Superalloys, John Wiley, New York, 1972.

J.K. Tien, T. Caulfield, Superalloys, Supercomposites and Superceramics, Academic Press, London, 1989.

M. Preuss, J.W.L. Pang, P.J. Withers, G.J. Baxter, Metall. Mater. Trans. 33A (2002) 3227–3234.

M. Preuss, P.J. Withers, G.J. Baxter, Mater. Sci. Eng. A 437 (2006) 38-45.

Z.W. Huang, H.Y. Li, M. Preuss, M. Karadge, P. Bowen, S. Bray, and G. Baxter, Metall. Mater. Trans. 38A (2007) 1608-1620.

Z.W. Huang, H.Y. Li, G. Baxter, S. Bray, P. Bowen, Adv. Mater. Res. 278 (2011) 440-445.

J. Gayda, Alloy 10: A 1300 F Disk Alloy, NASA/TM-2000-210358, NASA Glenn Research Center, Cleveland, OH, 2000.

T.P. Gabb, J. Gayda, P.T. Kantzos, T. Biles, W. Konkel, The tensile properties of advanced Nickel-based disk superalloys during quenching heat treatments, NASA/TM-2001-211218, NASA Glenn Research Center, Cleveland, OH, 2001.

J.R. Kattus, Ni-Base Alloys: Mar-M247 (Code 4218), Aerospace Structural Metals Handbook, Purdue Research Foundation, West Lafayette, Indiana, 1999.

S.L. Semiatin, K.E. MacClary, A.D. Rollett, C.G. Roberts, E.J. Payton, F. Zhang, T.P. Cabb, Metall. Mater. Trans. A 44 (2012) 2778-2798.

P.R.A.A. Silva, R. Baldan, C.A. Nunes, C.C. Caelho, A.M.S. Costa, Mater. Characterization 75 (2013) 214-219.

D. Rice, P. Kantzos, B. Hann, J. Neumann, and R. Helmink: Superalloys 2008, TMS, Materials Park, PA, 2008, pp. 139–47.

D. Workman and J. Gould, Development of Prototype Joints between Cast Superalloy Blades and Powder Metallurgy Disks, Edison Welding Institute, Columbus, OH, 2012.

V.I. Vill, Friction Welding of Metals, American Welding Society, New York, NY, 1962, 114 p.

P. N. Quested, R. F. Brooks, L. Chapman, R. Morrell, Y. Youssef, K.C. Mills, Mater. Sci. technol. 25 (2009) 154-162.

R.A. Rick, A.J. Porter, R.C. Ecob, Acta Metall. 31 (1983) 43-53.

E. Orowan, Proc. Inst. Mech. Eng. 150 (4) (1943, 140-167.

P.J. Blau, S.D. Henry, C.M. Davidson, T.B. Zorc, and D.R. Levick, eds.: Friction, Lubrication and Wear Technology, ASM Handbook, vol. 18, ASM International, Materials Park, OH, 1992.

L.B. Yang, J.C. Gebelin, R.C. Reed, Mater. Sci. Techn. 27 (2011) 1249-1264.

F.H. Daus: Ph.D. Thesis, University of Birmingham, Birmingham, UK, 2009.

L.B. Yang: PhD. Thesis, University of Birmingham, Birmingham, UK, 2010.

A. Nadai, J. Appl. Phys. 8 (1937) 205-213.

L. Wang, M. Preuss, P.J. Withers, G. Baxter, P. Wilson, Metall. Mater. Trans. 36B (2005) 513-523.

F. Daus, H.Y. Li, G. Baxter, S. Bray, P. Bowen, Mater. Sci. Techn. 23 (2007) 1424-1432.

O. Midling, O. Grong, Acta Metall Mater. 42 (1994) 1595-1609.

H. Mei, Y. Liu, L. Cheng, J. Mater. Sci. 47 (2012) 2278-2283.

J. Evans, J. Mater. Eng. Perf. 19 (2010) 1001-1004.

D. Landolt, Corrosion and Surface Chemistry of Metals, EPFL Press, Lausanne, Switzerland, 2003.

Acknowledgments

Inertia friction welding was conducted at the Edison Welding Institute, Columbus, Ohio. The authors thank Mr. D. Workman (EWI) for technical help. Discussions and valuable comments from Dr. S.S. Babu are greatly appreciated. ONS acknowledges financial support through the Air Force on-site contract FA8650-10-D-5226 conducted by UES, Inc., Dayton, OH.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 16, 2014.

Rights and permissions

About this article

Cite this article

Senkov, O.N., Mahaffey, D.W., Semiatin, S.L. et al. Inertia Friction Welding of Dissimilar Superalloys Mar-M247 and LSHR. Metall Mater Trans A 45, 5545–5561 (2014). https://doi.org/10.1007/s11661-014-2512-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-014-2512-x