Abstract

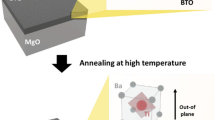

In the present work, an improved method is developed for preparing highly pure ultrathin barium titanate nanostructured films with desired structural and morphological characteristics. In contrast to other approaches, our method can be carried out at a relatively lower temperature to obtain barium titanate ultrathin films free from secondary phases, impurities, and cracks. To reach an in-depth understanding of scientific basis of the proposed process, and in order to disclose the mechanism of formation and growth of barium titanate ultrathin film, in-detail analysis is carried out using XRD, SEM, FE-SEM, and AFM techniques aided by theoretical calculations. The effects of calcining temperature on the nanoscale structure development, phase transition, morphology evolution, and growth mechanism of the ultrathin barium titanate nanostructured films are studied. XRD results indicate that the reaction leading to the formation of the barium titanate initiates at about 873 K (600 °C) and completes at about 1073 K (800 °C). Moreover, secondary phases are not detected in the XRD patterns of the ultrathin films which this observation ensures the phase purity of the ultrathin films. The results show that the ultrathin films are nanothickness and nanostructured leading to the enhancement of rate of diffusion by activating short-circuit diffusion mechanisms. The high rate of the diffusion enhances the rate of the formation of barium titanate and also prevents from the formation of the secondary phases in the final products. SEM and AFM results indicate that the deposited ultrathin films are crack-free exhibiting a dense nanogranular structure. The results indicate that the root-mean square (RMS) roughness of the ultrathin films is in the range of 1.66 to 6.71 nm indicating the surface of the ultrathin films is smooth. RMS roughness also increases with an increase in the calcining temperature which this observation seems to be related to the grain growth process. Finally, based on the observed results, the mechanism of the formation and growth of the ultrathin barium titanate nanostructured films is deeply disclosed.

Similar content being viewed by others

References

M.J. Dicken, K. Diest, Y.B. Park, and H.A. Atwater: J. Cryst. Growth, 2007, vol. 300, pp. 330–35.

F. He, W. Ren, G. Liang, P. Shi, X. Wu, X. Chen: Ceram. Int., 2013, vol. 39, pp. S481-85.

R. Ashiri: Vib. Spec., 2013, vol. 66, pp. 24-29.

A. Solanki, J. Shrivastava, S. Upadhyay, S. Choudhary, V. Sharma, P. Sharma, P. Kumar, P. Kumar, Sh. Ehrman, V.R. Satsangi, R. Shrivastav, S. Dass: Curr. Appl. Phys., 2013, vol. 13, pp. 344-50.

L.A. Patil, D.N. Suryawanshi, I.G. Pathan, D.G. Patil: Sens. Actuat., 2014, vol. B195, pp. 643-50.

R. Ashiri: Metall. Mater. Trans. B, 2014, DOI:10.1007/s11663-014-0057-4.

M.C. Gust, N.D. Evans, L.A. Momoda, M.L. Mecartney: J. Am. Ceram. Soc., 1997, vol. 80, pp. 2828-36.

O. Harizanov, A. Harizanova: Mater. Sci. Eng., 2004, vol. B106, pp. 191-95.

H. Kniepkamp, W. Heywang: Z. Angew. Phys., 1954, vol. 6, pp. 385-90.

W. Li, Zh. Xu, R. Chu, P. Fu, J. Hao: J. Alloys Compd., 2009, vol. 482, pp. 137-40.

B. Lee, J. Zhang: Thin Solid Films, 2001, vol. 388, pp. 107-113.

R. Ashiri, A. Nemati, M. Sasani Ghamsari, H. Aadelkhani: J. Non-Cryst. Solids, 2009, vol. 355, pp. 2480–84.

W. Duffy, B.L. Cheng, M. Gabbay: Metall. Mater. Trans. A, 1995, vol. 26A, pp. 1735-39.

W. Jiang, W. Cai, Z. Lin, Ch. Fu: Mater. Res. Bull., 2013, vol. 48, pp. 3092-97.

R. Ashiri, A. Nemati, M. Sasani Ghamsari, S. Sanjabi, and M. Aalipour: Mater. Res. Bull., 2011, vol. 46, pp. 2291-95.

S. Förster, W. Widdra: Surf. Sci., 2010, vol. 604, pp. 2163-69.

C.H. Lei: Thin Solid Films, 2006, vol. 515, pp. 1701-07.

R. Ashiri: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 4414-26.

C.A. Vasilescu, M. Crisan, A.C. Ianculescu, M. Raileanu, M. Gartner, M. Anastasescu, N. Dragan, D. Crisan, R. Gavrila, R. Trusca: Appl. Surf. Sci., 2013, vol. 265, pp. 510-18.

C.K. Tan, G.K.L. Goh, G.K. Lau: Thin Solid Films, 2008, vol. 516, pp. 5545-50.

A. Kaźmierczak-Bałata, J. Bodzenta, M. Krzywiecki, J. Juszczyk, J. Szmidt, P. Firek: Thin Solid Films, 2013, vol. 545, pp. 217-21.

A. Ianculescu, B. Despax, V. Bley, Th. Lebey, R. Gavrila, N. Dragan: J. Eur. Ceram. Soc., 2007, vol. 27, pp. 1129-35.

H.X. Zhang, Mater. Chem. Phys., 2000, vol. 63, pp. 174-77.

T.M. Stawski, W.J.C. Vijselaar, O.F. Göbel, S.A. Veldhuis, B.F. Smith, D.H.A. Blank, J.E. Elshof: Thin Solid Films, 2012, vol. 520, pp. 4394-4401.

M.R. Loghman-Estarki, M. Hajizadeh-Oghaz, H. Edris, R. Shoja Razavi: Cryst. Eng. Commun., 2013, vol. 15, pp. 5898-5909.

D. Guo, Y. Gong, Ch. Wang, Q. Shen, L. Zhang: Mater. Lett., 2013, vol. 95, pp. 55-58.

X. Yang, Zh. Ren, G. Xu, Ch. Chao, Sh. Jiang, Sh. Deng, G. Shen, X. Wei, and G. Han: Ceram. Int., 2014, in press.

D. Levasseur, H.B. El-Shaarawi, S. Pacchini, A. Rousseau, S. Payan, G. Guegan, M. Maglione: J. Eur. Ceram. Soc., 2013, vol. 33, pp. 139-46.

M. Farhadi-Khouzani, Z. Fereshteh, M.R. Loghman-Estarki, and R. Shoja Razavi: J. Sol-Gel Sci. Technol., 2012, vol. 64, pp. 193–99.

R.W. Schwartz, P.G. Clem, J.A. Voigt, E.R. Byhoff, M.V. Stry, Th.J. Headley, N.A. Missert: J. Am. Ceram. Soc., 1999, vol. 82, pp. 2359-67.

H. Kumazawa, K. Masuda: Thin Solid Films, 1999, vol. 353, pp. 144-48.

W. Cai, Ch. Fu, J. Gao: Physica, 2011, vol. B406, pp. 3583-87.

R.N. Das, P. Pramanik: J. Am. Ceram. Soc., 2010, vol. 93, pp. 1869-73.

R. Ashiri, A. Nemati, and M. Sasani Ghamsari: Ceram. Int., 2014, vol. 40, pp. 8613–19.

B.D. Cullity: The Elements of X-Ray Diffraction, Second ed., California, Addison Wesley, 1978.

H.B. Sharma, H.N.K. Sarma: Thin Solid Films, 1998, vol. 330, pp. 178-82.

M. Manso-Silvan, L. Fuentes-Cobas, R.J. Martin-Palma: Surf. Coat. Technol., 2002, vol. 151, pp. 118-21.

Z.G. Hu, Y.W. Li, M. Zhu, Z.Q. Zhu, J.H. Chu: Phys. Lett., 2008, vol. A372, pp. 4521-26.

X. Xing, J. Deng, J. Chen, G. Liu: J. Alloys Compd., 2004, vol. 384, pp. 312-17.

R. Thomas, D.C. Dube, M.N. Kamalasanan, S. Chandra: Thin Solid Films, 1999, vol. 346, pp. 212-25.

C.J. Brinker and G.W. Scherer: Sol-Gel Science, Academic Press, Boston, 1990.

J. Yuk, T. Troczynski: Sensors Actuators, 2003, vol. B94, pp. 290–93.

T.M. Stawski, S.A. Veldhuis, R. Besselink, H.L. Castricum, G. Portale, D.H.A. Blank, J.E. Ten Elshof: J. Phys. Chem., 2012, vol. C116, pp. 425-34.

H-Y. Tian, W-G. Luo, X.-H. Pu, P-S. Qiu, X-Y. He, A-L. Ding: Thermochim. Acta, 2000, vol. 360, pp. 57-62.

F. Baeten, B. Derks: J. Eur. Ceram. Soc., 2006, vol. 26, pp. 589-92.

U. Chaimongkon, A. Thongtha, T. Bongkarn: Curr. Appl. Phys., 2011, vol. 11, pp. S70-76.

M.C. Cheung: Nanostruct. Mater., 1999, vol. 11, pp. 837-44.

W.D. Callister: Fundamentals of Materials Science and Engineering, fifth ed., Wiley, New York, 2004.

M. Baurer, S.-J. Shih, C. Bishop, M.P. Harmer, D. Cockayne, M.J. Hoffmann: Acta Mater., 2010, vol. 58, pp. 290-300.

R. Ashiri: M.Sc. Dissertation, Sharif University of Technology, Tehran, Iran, 2008.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 25, 2014.

Rights and permissions

About this article

Cite this article

Ashiri, R. A Mechanistic Study of Nanoscale Structure Development, Phase Transition, Morphology Evolution, and Growth of Ultrathin Barium Titanate Nanostructured Films. Metall Mater Trans A 45, 4138–4154 (2014). https://doi.org/10.1007/s11661-014-2352-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-014-2352-8