Abstract

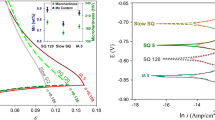

Different thermomechanical treatments were applied to a high strength low carbon steel with a novel chemical composition. As a result, three different microstructures were produced with dissimilar mechanical and corrosion properties. Subsequently, a tempering heat treatment was applied to redistribute the phases in the steel. Microstructure A with 56 pct martensite and 32 pct bainite presented high strength but medium ductility; microstructure C with 95 pct ferrite and 3 pct martensite/austenite resulted in low strength and high ductility, and finally microstructure B with 98 pct bainite and 2 pct martensite/austenite resulted in high strength and ductility. Alternatively the corrosion behavior obtained by polarization curves was characterized in 0.1 M H2SO4, 3 M H2SO4, 3.5 wt pct NaCl, and NS4 solutions resulting in similar magnitudes, while the corrosion behavior acquired by electrochemical impedance spectroscopy had slightly differences in 3 M H2SO4.

Similar content being viewed by others

References

H. Van Long, D. Jean-François, L.D.P. Lam and R. Barbara, J. Constr. Steel Res. 2011, vol. 67, pp. 1001-21.

B.H. Smith, S. Szyniszewski, J.F. Hajjar, B.W. Schafer and S.R. Arwade, J. Constr. Steel Res. 2012, vol. 71, pp. 1-10.

H.K.D.H. Bhadeshia, Prog. Mater. Sci. 2012, vol. 57, pp. 268-435.

A. Bakkaloğlu, Mater. Lett. 2002, vol. 56, pp. 263-72.

R. Song, D. Ponge, D. Raabe, J.G. Speer and D.K. Matlock, Mater. Sci. Eng. A Struct. 2006, vol. 441, pp. 1-17.

P.C.M. Rodriguez, E.V. Pereloma and D.B. Santos, Mater. Sci. Eng. A Struct. 2000, vol. 283, pp. 136-43.

G.R. Ebrahimi, M. Javdani and H. Arabshahi, Braz. J. Phys. 2010, vol. 40, pp. 454-58.

X. Deng and D. Ju, Phys. Procedia 2013, vol. 50, pp. 368-74.

J. Niu, L. Qi, Y. Liu, L. Ma, Y. Feng and J. Zhang, Trans. Nonferrous Met. Soc. 2009, vol. 19(Supplement 3), pp. 573–578.

A.K. Sinha, In Ferrous Physical Metallurgy (Butterworths: Boston, 1989), pp 523-608.

D.M. Drazic: in Modern Aspects of Electrochemistry, J.O’M. Bockris and B.E. Conway, eds., Plenum Press, New York, 1989, p. 69.

W.J. Lorenz and K.E. Heusler: in Corrosion Mechanism, F. Mansfeld, ed., Marcel Dekker, New York, 1987, p. 1.

M. Gomez, P. Valles and S.F. Medina, Mater. Sci. Eng. A Struct. 2011, vol. 528, pp. 4761-73.

J. Majta, R. Kuziak and M. Pietrzyk, J. Mater. Process. Technol. 1998, vol. 80–81, pp. 524-30.

R.D.K. Misra, Z. Jia, R. O’Malley and S.J. Jansto, Mater. Sci. Eng. A Struct. 2011, vol. 528, pp. 8772-80.

S.N. Prasad and D.S. Sarma, Mater. Sci. Eng. A Struct.. 2005, vol. 399, pp. 161-72.

P.R. Spena and D. Firrao, Mater. Sci. Eng. A Struct.. 2013, vol. 560, pp. 208-15.

J. Zrník, T. Kvackaj, A. Pongpaybul, P. Sricharoenchai, J. Vilk and V. Vrchovinsky, Mater. Sci. Eng. A Struct. 2001, vol. 319–321, pp. 321-25.

I.N. Bastos, S.S.M. Tavares, F. Dalard and R.P. Nogueira, Scripta Mater. 2007, vol. 57, pp. 913–16.

S. Bordbar, M. Alizadeh and S.H. Hashemi, Mater. Des. 2013, vol. 45, pp. 597-604.

S. Al-Hassan, B. Mishra, D.L Olson and M.M. Salama, Corrosion 1998, vol. 54, pp. 480–91.

D.A. López, S.N. Simison and S.R. de Sánchez, Electrochim. Acta 2003, vol. 48, pp. 845-54.

K. Videm, J. Kvarekvaal, T. Pérez, and G. Fitzsimons: CORROSION/96, Paper No. 1, NACE, Houston, 1996.

F. Farelas, M. Galicia, B. Brown, S. Nesic and H. Casteneda, Corros. Sci. 2010, vol. 52, pp. 509-17.

R. Chu, W. Chen, S.H. Wang, F. King, T.R. Jack and R.R. Fessler, Corrosion 2004, vol. 60, pp. 275-83.

D. Clover, B. Kinsella, B. Pejcic and R. De Marco, J. Appl. Electrochem. 2005, vol. 35, pp. 139-49.

ASTM: E-407 Standard Practice for Microetching Metals and Alloys, ASTM International, West Conshohocken, 1999.

E. Girault, P. Jacques, P. Harlet, K. Mols, J. Van Humbeeck, E. Aernoudt and F. Delannay, Mater. Charact. 1998, vol. 40, pp. 111-18.

B.L. Li, A. Godfrey, Q.C. Meng, Q. Liu and N. Hansen, Acta Mater. 2004, vol. 52, pp. 1069-81.

ASTM: E18 Standard Test Method for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials, ASTM International, West Conshohocken, 2005.

ASTM: E8 Standard Test Method for Tension Testing of Metallic Materials, ASTM International, West Conshohocken, 2005.

T. Gladman: The Physical Metallurgy of Microalloyed Steels (The Institute of Materials of Cambridge, London, 1997).

A. Itman, K.R. Cardoso and H.J. Kestenbach, Mater. Sci. Technol. Ser. 1997, vol. 13, pp. 49-55.

H. Kejian and T.N. Baker, Mater. Sci. Eng. A Struct. 1993, vol. 169, pp. 53-65.

W. Wang and H.R. Wang, Mater. Lett. 2007, vol. 61, pp. 2227-30.

P. Maugis and M. Gouné, Acta Mater. 2005, vol. 53, pp. 3359-67.

Y. Kang, Y. Hao, F. Jie, K. Wang, and Z. Wang: Mater. Sci. Eng. A Struct., 2003, vol. 351, pp. 265-71.

ASTM: E 112 Standard Test Methods for Determining Average Grain Size, ASTM International, West Conshohocken, 2004.

A.K. Sinha: Ferrous Physical Metallurgy. (Butterworths, Boston, 1989).

S. Nagakura, Y. Hirotsu, M. Kusnoki, Susuki. T. and Y. Nakamura, Metall. Trans. A, 1983, vol. 14A, pp. 1025-31.

B.K. Jha and N.S. Mishra, Mater. Sci. Eng. A Struct. 1999, vol. 263, pp. 42-55.

R. Feng, S. Li, Z. Li and L. Tian, Mater. Sci. Eng. A Struct. 2012, vol. 558, pp. 205-10.

A.J. Bard and L.R. Faulkner: Electrochemical Methods Fundamentals and Applications. Wiley, New York, 2001.

A. Davydov, K.V. Rybalka, L.A. Beketaeva, G.R. Engelhardt, P. Jayaweera and D.D. Macdonald, Corros. Sci. 2005, vol. 47, pp. 195-215.

J.O.M. Bockris and A.K.N. Reddy, Modern Electrochemistry, Kluwer/Plenum: New York, 2000, p 1669.

K.H. Kim, S.H. Lee, N.D. Nam and J.G. Kim, Corros. Sci. 2011, vol. 53, pp. 3576-87.

G.V. Karpenko, A.K. Mindyuk, O.P. Savistskaya, and Yu.I. Babei: Sov. Mater. Sci., 1970, vol. 6, pp. 409–11.

Acknowledgments

Financial support from Consejo Nacional de Ciencia y Tecnología (CONACYT, México) Ph.D. scholarship to J.I.B.-F is gratefully acknowledged. In addition, the authors want to thank Ivan Puente Lee from Facultad de Química, UNAM, for his help in the SEM and TEM work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 21, 2013.

Rights and permissions

About this article

Cite this article

Barraza-Fierro, J.I., Campillo-Illanes, B., Li, X. et al. Steel Microstructure Effect on Mechanical Properties and Corrosion Behavior of High Strength Low Carbon Steel. Metall Mater Trans A 45, 3981–3994 (2014). https://doi.org/10.1007/s11661-014-2320-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-014-2320-3