Abstract

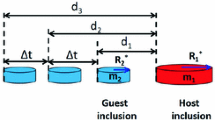

An in situ observation method was developed to investigate abnormal grain coarsening which occurs around the surface of steel during the vacuum-carburizing process. In this method, diffusion of carbon atoms in the vacuum carburizing was simulated by a cementite and steel diffusion couple. Abnormal grain coarsening, which appeared around the cementite and steel interface, was observed by a confocal scanning laser microscope. With this method, it was observed that when holding time was 60 seconds, the temperature at which the abnormal grain coarsening appeared in a specimen was higher when carburized than the temperature when not carburized. On the contrary, when holding time was 120 seconds, the temperature at which the abnormal grain coarsening appeared in a specimen was 10 K to 20 K lower than that in a non-carburized specimen. The validity of the observed results was confirmed by the calculated NbC fraction using Nb solubility and measured carbon content.

Similar content being viewed by others

References

S. Tsuji, I. Ishigami and K. Yamanaka: Trans. Jpn Inst. Met., 28 (1987), 48–56.

M. Sugiyama: Netsu Shori (J. Jpn Soc. Heat Treat.), 37 (1997), 154–60.

N.M. Ryzhov, A.E. Smirnov, R.S. Fakhurtdinov, L.M. Mulyakaev, and V.I. Gromov: Met. Sci. Heat Treat., 46 (2004), 230–35.

P. Kula, R. Pietrasik, K. Dybowski: J. Mater. Proc. Technol., 164–165 (2005), 876–81.

T. Machi: Netsu Shori (J. Jpn. Soc. Heat Treat.), 2005, vol. 45, pp. 80–83.

K. Ohbayashi: Denki Seiko (Electr. Furn. Steel), 2008, vol. 79, pp. 53–60.

N. Okumura: Netsu Shori (J. Jpn Soc. Heat Treat.), 2009, vol. 49, pp. 257–62.

K. Widanka: Powder Metall. Prog., 9 (2009), 165–72.

T. Morita and H. Matsumura: CAMP-ISIJ, 19 (2006), 1223.

T. Morita and H. Matsumura: CAMP-ISIJ, 19 (2006), 1225.

T. Morita and T. Hanyuda: Tetsu-to-Hagané, 92 (2006), 268–73.

T. Morita, K. Inoue, and T. Hanyuda: Denki Seiko (Electr. Furn. Steel), 2006, vol. 77, pp. 5–9.

T. Morita: Netsu Shori (J. Jpn Soc. Heat Treat.), 2009, vol. 49, pp. 237–42.

K. Tanaka, H. Ikehata, K. Nakanishi, and T. Nishikawa: Metall. Mater. Trans. A, 39A (2008), 1248–57.

K. Tanaka, H. Ikehata, H. Takamiya, and H. Mizuno: Tetsu-to-Hagané, 97 (2011), 130–35.

H. Ikehata, K. Tanaka, H. Takamiya, and H. Mizuno: ISIJ Int., 52 (2012), 1348–55.

S. Todo, M. Horimoto, T. Nishizawa: 17th Int. Fed. Heat Treat. Surf. Eng. Congr., 2008, pp. 117–20.

Y. Yogo, K. Tanaka, and K. Nakanishi: Mater. Trans., 50 (2009), 280–85.

Y. Yogo, H. Takeuchi, K. Tanaka, N. Iwata, K. Nananishi and T. Ishikawa: Microsc. Res. Techn., 72 (2009), 899–901.

Y. Yogo, H. Takeuchi,T. Ishikawa, N. Iwata and K. Nakanishia: Scripta Mater., 61 (2009), 1001–3.

H. Chikama, H. Shibata, T. Emi and M. Suzuki: Mater. Trans. 37 (1996), 620–26.

H. Yin, T. Emi, H. Shibata: ISIJ Int., 38 (1998), 794–801.

H. Yin, T. Emi and H. Shibata: Acta Mater., 47 (1999), 1523–37.

R.J. Dippenaar and D.J. Phelan: Metall. Mater. Trans. B, 34B (2003), 495–501.

H. Terasaki and Y. Komizo: Sci. Technol. Weld Joining, 11 (2006), 561–66.

D. Zhang, Y. Shintaku, S. Suzuki, and Y. Komizo: Metall. Mater. Trans. A, 43A (2012), 447–58.

P Kolmskog, A. Borgenstam, M. Hillert, P. Hedstrom, S.S. BABU, H. Terasaki, and Y. Komizo: Metall. Mater. Trans. A, 43A (2012), 4984–88.

J. Pak, D.W. Suh, and H.K.D.H. Bhadeshia: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 4520–24.

K. Narita: Trans. Iron. Steel. Inst. Jpn, 15 (1975) 145–52.

M. Hillert and L.-I. Staffansson: Acta Chem Scand. 24 (1970) 3618–26.

H. Ohtani, M. Hasebe and T. Nishizawa: CALPHAD 13 (1989) 183–204.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 1, 2013.

Rights and permissions

About this article

Cite this article

Yogo, Y., Tanaka, K. In Situ Observation for Abnormal Grain Coarsening in Vacuum-Carburizing Process. Metall Mater Trans A 45, 2834–2841 (2014). https://doi.org/10.1007/s11661-014-2233-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-014-2233-1