Abstract

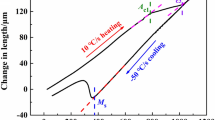

Using transmission electron microscopy, Mössbauer spectroscopy, and measurements of hardness, the carbide precipitation during tempering of steel X153CrMoV12 containing (mass pct) 1.55C, 11.90Cr, 0.70V, and 0.86Mo is studied after three treatments: quenching at RT and deep cryogenic treatment, DCT, at 77 K or 123 K (−196 °C or −150 °C). In contrast to some previous studies, no fine carbide precipitation after long-time holding at cryogenic temperatures is detected. After quenching at room temperature, RT, the transient ε(ε′) carbide is precipitated between 373 K and 473 K (100 °C and 200 °C) and transformed to cementite starting from 573 K (300 °C). In case of DCT at 123 K (−150 °C), only fine cementite particles are detected after tempering at 373 K (200 °C) with their delayed coarsening at higher temperatures. Dissolution of cementite and precipitation of alloying element carbides proceed at 773 K (500 °C) after quenching at RT, although some undissolved cementite plates can also be observed. After DCT at 123 K (−150 °C), the transient ε(ε′) carbide is not precipitated during tempering, which is attributed to the intensive isothermal martensitic transformation accompanied by plastic deformation. In this case, cementite is the only carbide phase precipitated in the temperature range of 573 K to 773 K (300 °C to 500 °C). If DCT is carried out at 77 K (−196 °C), the ε(ε′) carbide is found after tempering at 373 K to 473 K (100 °C to 200 °C). Coarse cementite particles and the absence of alloying element carbides constitute a feature of steel subjected to DCT and tempering at 773 K (500 °C). As a result, a decreased secondary hardness is obtained in comparison with the steel quenched at RT. According to Mössbauer studies, the structure after DCT and tempering at 773 K (500 °C) is characterized by the decreased fraction of the retained austenite and clustering of alloying elements in the α solid solution. It is suggested that a competition between the strain-induced transformation of the retained austenite and carbide precipitation during the wear can control the life of steel tools.

Similar content being viewed by others

References

D.N. Collins: Heat Treat. Met., 1996, 2, pp. 40-42.

S. Zhirafar, A. Rezaeian and M. Pugh: J. Mater. Process Technol., 2007, vol. 186, pp.298-303.

P. Baldissera and C. Delprete: Open Mech Eng. J., 2008, 2, pp. 1–11.

F. Meng, K. Tagashira, R. Azuma, H. Sohma: ISIJ Int., 1994, vol. 34, pp. 206-10.

Dong Y, Lin X and Xiao H, Heat Treat. Met., 1998, 3, pp. 55–59.

M. Pellizari and A. Molinari: in Proceedings of the 6th International Tooling Conference, J. Bergström, G. Fredriksson, M. Johansson, O. Kotik, and F. Thuvander, eds., Karlstad University, Karlstad, 2002, pp. 547–57.

P.F. Stratton: Mater. Sci. Eng. A 2007, vol. 449-451, pp. 809-12.

T. Yugandhar, P.K. Krishnan, C.V. Rao Bhaskar, and R. Kalidas: in Proceedings of the 6th International Tooling Conference, J. Bergström, G. Fredriksson, M. Johansson, O. Kotik, and F. Thuvander, eds., Karlstad University, Karlstad, 2002, pp. 559–69.

Y. Hirotsu, S. Nagakura: Acta Metall. 1972, vol. 20, pp. 645-55.

K.A. Taylor, G.B. Olson, M. Cohen and J.B. Vander Sande: Metall. Trans. A 1989, vol. 20, pp. 2749-65.

G.V. Kurdyumov, and O.P. Maksimova: Dokl Akad Nauk SSSR (in Russian), 1948, vol. 61, pp. 83–86. See also a corresponding review in English: O.P. Maximova: Metal Sci. Heat Treat., 1999, vol. 41, pp. 322–39.

J. Pietikainen: J Iron Steel Inst., 1968, vol. 206, pp. 74-78.

J.T. Eldis, M. Cohen: Metall. Trans. A, 1983, vol. 14, pp. 1007-1012.

V.G. Gavriljuk, W. Theisen, V.V. Sirosh, E.V. Polshin, A. Kortmann, G.S. Mogilny, Yu.N. Petrov, Ye.V. Tarusin: Acta Mater., 2013, vol. 61, pp. 1705-15.

D. Mohan Lal, S. Renganarayanan, and A. Kalanidhi: Cryogenics, 2001, vol. 41, pp. 149–55.

A. Molinari, M. Pellzzari, S. Gialanella, G. Straffelini, K.H. Stiasny: J. Mater. Process. Technol., 2001, vol. 118, pp. 350-55.

A.I. Tyshchenko, W. Theisen, A. Oppenkowski, S. Siebert, O.N. Razumov, A.P. Skoblik, V.A. Sirosh, Y.N. Petrov, V.G. Gavriljuk: Mater. Sci. Eng. A, 2010, vol. 527, pp. 7027-39.

D.V. Wilson: Acta Metall., 1957, vol. 5, pp. 293-302.

V.G. Gavriljuk, N.P. Kushnareva, V.G. Prokopenko: Fiz. Metall. Metalloved. (in Russian), 1976, vol. 42, pp. 1288-93.

V.G. Gavriljuk: Mater. Sci. Eng. A, 2003, vol. 345, pp. 81-89.

J.Y. Huang, Y.T. Zhu, X.Z. Liao, I.J. Beyerlein, M.A. Bourke, T.E. Mitchell: Mater. Sci. Eng. A, 2003, vol. 339, pp. 241-44.

F.J. da Silva, S.D. Franco, A.R. Machado, E.O. Ezugwu, A.M. Souza, Jr.: Wear, 2006, vol. 261, pp. 674-85.

V. Firouzdor, E. Nejati, F. Khomamizadeh: J. Mater. Process. Technol., 2008, vol. 206, pp. 467-72.

H. Berns, W. Trojahn: Härterei Technische Mitteilungen 1985, vol. 40, no. 2, pp. 65-72.

Acknowledgments

The authors thank Professor Hans Berns, Ruhr University Bochum, for a fruitful discussion and valuable remarks concerning the obtained results. This study was carried out within the frames of Project STCU 5039, the Science and Technology Centre of Ukraine, and the BMWi Project 16 IN 0451-3.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 21, 2013.

Rights and permissions

About this article

Cite this article

Gavriljuk, V.G., Sirosh, V.A., Petrov, Y.N. et al. Carbide Precipitation During Tempering of a Tool Steel Subjected to Deep Cryogenic Treatment. Metall Mater Trans A 45, 2453–2465 (2014). https://doi.org/10.1007/s11661-014-2202-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-014-2202-8