Abstract

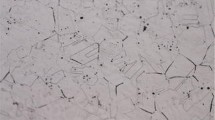

Recrystallization and partial re-melting processes have been developed for producing semi-solid feedstock in a solid state in which a globular microstructure is obtained by plastic deformation followed by reheating. In this research, to induce strain, a cast- and solution-treated Aluminum A356 (7 wt pct Si) alloy was subjected to a repetitive equal channel angular pressing process using a 90 deg die, up to a total accumulated strain of approximately 8 in route A (increasing strain through a sequence of passes with no rotation of the sample after each pass) at ambient temperature. The microstructural evolutions of deformed and reheated materials were studied by optical microscopy, scanning electron microscopy, and electron back-scattered diffraction analysis. In addition, the influences of pre-deformation on the recrystallization mechanism and liquid formation of A356 alloy were presented and discussed. The results are also supported by differential thermal analysis experiments. Evaluation of the observations indicated that the average cell boundary misorientation increased with increasing strain, so this increased misorientation accelerated the mobility of boundaries and recrystallization kinetics. Therefore, the recrystallization mechanism and kinetics affected by deformation, reheating condition, and intrinsic material properties determined the particle size in the semi-solid state.

Similar content being viewed by others

References

M.C. Flemings: Metall. Trans. A, 1991, vol. 22, pp. 957-981.

Z. Fan: Int. Mater. Rev., 2002, vol. 47, no. 2, pp. 49-85.

Y. Birol: J. Alloys Compd., 2009, vol. 473 (1–2), pp. 133–38.

J.G. Wang, H.Q. Lin, Y.Q. Li and Q.C. Jiang: J. Alloys Compd., 2008, vol. 457, pp. 251-258.

K. Lee, Y. N. Kwon and S. Lee: J. Alloys Compd., 2008, vol. 461, pp. 532-541.

J. C. Choi and H. J. Park: Mater. Process. Technol., 1998, vol. 82, pp. 107-116.

W. Lapkowski: Mater. Process. Technol., 1998, vols. 80-81, pp. 463-468.

H. V. Atkinson: Prog. Mater Sci., 2005, vol. 50, pp. 341-412.

R.D. Doherty, K. Kashyap and S. Panchanadeeswaran: Acta Metall. Mater., 1993, vol. 41, pp. 3029-3053.

E. Tzimas and A. Zavaliangos: Mater. Sci. Eng. A, 2000, vol. 289, pp. 217-227.

N. Saklakoglu, I. E. Saklakoglu, M. Tanoglu, O. Oztas and O. Cubukcuoglu: J. Mater. Process. Technol., 2004, vol. 148, pp. 103-107.

X. Ming-Xu, Z. Hong-Xing, Y. Sen and L. Jian-Guo: Mater. Des., 2005, vol. 26, pp. 343-349 .

H.Q. Lin, J. G. Wang, H.Y. Wang and Q.C. Jiang: J. Alloys Compd., 2007, vol. 431, pp. 141-147.

Y. Sirong, L. Dongcheng and N. Kim: Mater. Sci. Eng. A, 2006, vol. 420, pp. 165-170.

L. Sang, L. Jung and L. Young: J. Mater. Process. Technol., 2001, vol. 111, pp. 42-47.

A. M. Kliauga and M. Ferrante: Acta Metall. Mater., 2005, vol. 53, pp. 345-356.

H. V. Atkinson, K. Burke and G. Vaneetveld: Mater. Sci. Eng. A, 2008, vol. 490, pp. 266-276.

J. Jiang, Y. Wang and S. Luo: Mater. Charact., 2007, vol. 58, pp. 190-196.

J. Jiang and S. Luo: Trans. Nonferrous Met. Soc. China, 2007, vol. 17, pp. 46-50.

T.J. Chen, G.X. Lu, Y. Ma, Y.D. Li and Y. Hao: J. Alloys Compd., 2009, vol. 486, pp. 124-135.

V.M. Segal: Mater. Sci. Eng. A, 1995, vol. 197, pp. 157-64.

TG. Langdon: Mater. Sci. Eng. A, 2007, vol. 462, pp. 3-11.

S. Mahesh, I. Beyerlein and C. Tome: Scripta Mater., 2005, vol. 53, pp. 965-969.

H. Conra and K. Jung: Scripta Mater., 2005, vol. 53, pp. 581-584.

M. Haouaoui, K. Hartwig and E. Payzant: Acta Metall. Mater., 2005, vol. 53, pp. 801-810.

S. Ashouri, M. Nili- Ahmadabadi, M. Moradi and M. Iranpour: J. Alloys Compd., 2008, vol. 466, pp. 67-72.

M. Moradi, M. Nili-Ahmadabadi, B. Heidarian and S. Ashouri: J. Alloys Compd., 2009, vol. 487, pp. 768-775.

M. Moradi, M. Nili-Ahmadabadi, B. Poorganji, B. Heidarian, M. H. Parsa and T. Furuhara: Mater. Sci. Eng. A, 2010, vol. 527, pp. 4113-4121.

M. Moradi, B. Heidarian and M. Nili-Ahmadabadi: Int. J. Mater. Form., 2009, vol. 2, pp. 85-88.

P. K. Seo and C. G. Kang: J. Mater. Process. Technol., 2005, vols.162-163, pp. 402-409.

J. C. Zhao: Methods for phase diagram determination, 2007, First Edition, Elsevier.

F.J. Humphreys and M. Hatherly: Recrystallization and Related Annealing Phenomena, 2004, 2nd Edition, Elsevier, New York, NY.

P. J. Hurley, F. J. Humphreys and M. Ferry: Acta Metall. Mater., 2000, vol. 48, pp. 2543-2556.

S.S. Gorelik: Recrystallization in Metals and Alloys, 1981, Mir publishers, Moscow.

A. Lima and F. K Kowata: Proceeding of 8th International Conference on Semi-Solid Processing of Alloys and Composites, Cyprus, 2004.

H.V. Atkinson and D. Liu: Mater. Sci. Eng. A, 2008, vol. 496, pp. 439-446.

P. Babaghorbani, S. Salarfar and M. Nili-Ahmadabadi: Solid state phenom., 2006, vols. 116-117, pp. 201-205.

ASM Metals Handbook, Casting, 9 ed, vol. 15, pp. 56–57.

P. Suwanpinij, U. Kitkamthorn2, I. Diewwanit and T. Umeda: Mater. Trans., 2003, vol. 44, pp. 845-852.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 18, 2010.

Rights and permissions

About this article

Cite this article

Moradi, M., Nili-Ahmadabadi, M., Poorganji, B. et al. EBSD and DTA Characterization of A356 Alloy Deformed by ECAP During Reheating and Partial Re-melting. Metall Mater Trans A 45, 1540–1551 (2014). https://doi.org/10.1007/s11661-013-2093-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-013-2093-0