Abstract

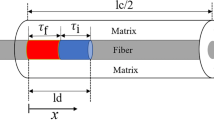

The relationship between pretension and residual stress of an aluminum wire reinforced with 45 vol pct continuous Nextel™ 610 alumina fibers is investigated. It is shown that as pretension stress increases, the matrix residual stress decreases. A transition in matrix residual stress from tension to compression occurs at a pretension stress of about 80 MPa. The initial rapidly decreased residual stress caused by pretension at relatively low pretension stresses is a result of matrix elastic compressive deformation; while the later gradually decreased residual stress at higher pretension stresses comes from matrix plastic compressive deformation. As the matrix yield stress and hardening exponent increase, the decrease in matrix residual stress with pretension stress is more rapid and the absolute value of matrix residual stress increases. An analytical model suitable for fiber-reinforced metal matrix composites (MMCs) with strong interfacial bonding is developed to describe the relationship between pretension and matrix residual stress and is shown to be in good agreement with the experimental and finite-element calculated results. The pretension-dependent matrix residual stress phenomenon suggests that the mechanical properties of fiber-reinforced MMCs associated with matrix residual stress may be effectively improved by applying tensile loads.

Similar content being viewed by others

References

H. E. Deve, and C. McCullough: JOM, 1995, vol. 47(7), pp. 33-37.

I. Kientzl, and J. Dobranszky : Mater Sci Forum, 2007, vol. 537-538, pp. 191-197.

D.J. Johnson, T.L. Anderson, and H.E. Deve: Power Engineering Society Summer Meeting, Vancouver, BC, 2001, vol. 1, pp. 175–79.

H.E. Deve, R. Clark, J. Stovall, S. Barrett, R. Whapham, and W. Uesnel: CIGRE Session, Paris, France, 2006, pp. B2–314, unpublished.

H.A. Samms: Electrical Transmission and Substation Structures Conference (ASCE), Fort Worth, Texas, US, 2009, pp. 1–10.

J. X. Zhang, Y. X. Pan, Z.W. You, and Q.Q. Ma: East China Electric Power, 2010, vol. 38(7), pp. 1026-1027.

W.L. Zhang, M.Y. Gu, J.Y. Chen, A.G. Wu, F. Zhang, and H.E. Deve: Mater Sci Eng, 2003, vol. A341, pp. 9-17.

U. Ramamurty, F.W. Zok, F.A. Leckie, and H.E. Deve: Acta Mater, 1997, vol. 45(11), pp. 4603- 4613.

C. McCullough, H.E. Deve, and T.E. Channel: Mater. Sci. Eng., 1994, vol. A189(12), pp. 147–54.

L. Weber, P. Canalis-Nieto, A. Rossoll, and A. Mortensen: Acta Mater, 2000, vol. 48(12), pp. 3235-3244.

R.J. Arsenault, and M. Taya: Acta Metall, 1987, vol. 35(3), pp. 651-659.

K.G. Dassios, D.G. Aggelis, E.A. Kordatos, and T.E. Matikas: Composites Part A, 2013, vol. 44, pp. 105-113.

Z. Zhang, and D.L. Chen: Scripta Mater, 2006, vol. 54, pp. 1321-1326.

M.M. Aghdam, and A. Khojeh: Compos Struct, 2003, vol. 62(3-4), pp. 285-290.

G. Meijer, F. Ellyin, and Z. Xia: Composites Part B, 2000, vol. 31(1), pp. 29-37.

M.R. James: Third International Conference on Residual Stress, Tokushima, Japan, 1991, pp. 555–60.

C. Liu, F. Zhang, G.D. Zhang, and N. Masaki: J Mater Sci, 2004, vol. 39(8), pp. 2923-2925.

Y. Ward, R.J. Young, and R.A. Shatwell: Composites Part A, 2002, vol. 33(10), pp. 1409-1416.

P. Bystricky, and H. Bjerregard: Metall Mater Trans, 1999, vol. A30(7), pp.1843-1865.

E.R. Olivasa, J.G. Swadener, and Y.L. Shen: Scripta Mater, 2006, vol. 54(2): 263-268.

F. Bouafiaa, B. Seriera, and B.A.B. Bouiadjra: Comput Mater Sci, 2012, vol. 54, pp. 195-203.

H. Choo, M.A.M. Bourke, and M.R. Daymond: Compos Sci Technol, 2001, vol. 61(12), pp. 1757-1772.

W.L. Zhang, D.Y. Ding, M.Y. Gu: Mater Sci Eng, 2010, vol. 527A(26), pp. 7109–14.

W. Zhang, S. Li, and S.R. Nutt: J Mater Sci Technol, 2009, vol. 25(2), pp. 281-288.

A. Roatta, and R.E. Bolmaro: Mater Sci Eng, 1997, vol. 229(1-2), pp.182-191.

H.Y. Zhang, P.M. Anderson, and G.S. Daehn: Metall. Mater. Trans. A, 1994, vol. 25A, pp. 415–25.

H. Li, J.B. Li, L.Z. Sun, and Z.G. Wang: Compos Sci Technol, 1997, vol. 57(2), pp. 165-172.

H. Li, D.Z. Wang, J.B. Li, Z.G. Wang, and C.R. Chen: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 2001–09.

N. Shi, R.J. Arsenault, A.D. Krawitz, and L.F. Smith: Metall. Trans. A, 1993, vol. 24A, pp. 187-196.

R. Hill: J Mech Phys Solids, 1964, vol. 12, pp. 199-212.

R. Hill: J Mech Phys Solids, 1964, vol. 12, pp. 213-218.

B. Moser, A. Rossoll, L. Weber, O. Beffort, and A. Mortensen: Composite Part A, 2001, vol. 32(8): 1067-1075.

R.Q. Ye, B.Q. Han, and E.J. Lavernia: Metall Mater Trans, 2005, vol. 36A, pp. 1833-1840.

3M: Nextel™ Ceramic Fiber Technical Notebook, 3M Ceramic Fiber Products, 3M Center, St Paul, MN, 1997.

Z.T. Wang, and R.Z. Tian: Handbook of aluminum alloy and processing, Press of Central South University of Technology, Changsha, 1989.

Acknowledgments

The authors would like to acknowledge the financial support of the National Natural Science Foundation (Nos. 51171108, 51071100, 51131004), the National Basic Research Program (973 Program) (No. 2012CB619600), the National High-Tech R&D Program (863 Program) (No. 2012AA030311), and Shanghai Science & Technology Committee (No. 11JC1405500). The authors are grateful for the supply of the composite wires by 3M (St. Paul, MN).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 23, 2013.

Rights and permissions

About this article

Cite this article

Dai, X., Zhang, W., Gao, P. et al. Pretension-Dependent Residual Stress of Alumina Fiber-Reinforced Composite Wire. Metall Mater Trans A 45, 1559–1566 (2014). https://doi.org/10.1007/s11661-013-2087-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-013-2087-y