Abstract

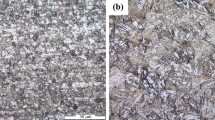

Highly cold worked (HCW) low carbon steel sheets with cellular structure in the range of 200 to 300 nm are fabricated via constrained groove pressing process. Joining of the sheets is carried out by resistance spot welding process at different welding currents and times. Thereafter, failure behavior of these welded samples during tensile-shear test is investigated. Considered concepts include; failure load, fusion zone size, failure mode, ultimate shear stress, failure absorbed energy, and fracture surface. The results show that HCW low carbon steel spot welds have higher failure peak load with respect to the as-received one at different welding currents and times. Also, current limits for failure mode transition from interfacial to pullout or from pullout to tearing are reduced for HCW samples. Fusion zone size is the main geometrical factor which affects the failure load variations. Ultimate shear stress of spot welds is increased with decreasing the heat input and for HCW samples at a specific welding current and time, it is lower than that of the as-received ones. Before pullout mode, failure absorbed energy (FAE) for HCW low carbon steel spot welds is higher than that of the as-received one, but after failure mode transition, trend would be vice versa and FAE of the as-received spot welds is extremely higher (about 3 times). In addition, spot welds fracture surface (in interfacial failure mode) for HCW sample is more dimpled which indicates higher energy absorption than that of the as-received one.

Similar content being viewed by others

References

J.W. Lee and J.J. Park: J. Mater. Process. Technol., 2002, vol. 130–131, pp. 208-213.

D.H. Shin, J.J. Park, Y.S. Kim, and K.T. Park: Mater. Sci. Eng., A, 2002, vol. 328, pp. 98-103.

A. Krishnaiah, U. Chakkingal, and P. Venugopal: Mater. Sci. Eng., A, 2005, vol. 410–411, pp. 337-340.

A. Krishnaiah, U. Chakkingal, and P. Venugopal: Scripta Materialia, 2005, vol. 52, pp. 1229-1233.

S.C. Yoon, A. Krishnaiah, U. Chakkingal, and H.S. Kim: Comput. Mater. Sci., 2008, vol. 43, pp. 641-645.

F. Khodabakhshi and M. Kazeminezhad: Mater. Des., 2011, vol. 32, pp. 3280-3286.

F. Khodabakhshi, M. Kazeminezhad, and A.H. Kokabi: Mater. Sci. Eng., A, 2010, vol. 527, pp. 4043-4049.

F. Khodabakhshi and M. Kazeminezhad: Mater. Sci. Eng., A, 2011, vol. 528, pp. 5212-5218.

P. Marashi, M. Pouranvari, S. Amirabdollahian, A. Abedi, and M. Goodarzi: Mater. Sci. Eng., A, 2008, vol. 480, pp. 175-180.

M. Pouranvari: Mater. Sci. Eng., A, 2012, vol. 546, pp. 129-138.

M. Pouranvari and S.P.H. Marashi: Mater. Des., 2010, vol. 31, pp. 3647-3652.

Miller-Handbook for Resistance Spot Welding, 06, 2012.

Ruukki-Resistance Welding Manual, 11, 2013.

F. Khodabakhshi, M. Kazeminezhad, and A.H. Kokabi: Mater. Sci. Eng., A, 2011, vol. 529, pp. 237-245.

F. Khodabakhshi, M. Kazeminezhad, and A.H. Kokabi: Mater. Charact., 2012, vol. 69, pp. 71-83.

S.H. Lin, J. Pan, T. Tyan, and P. Prasad: Int. J. Solids Struct., 2003, vol. 40, pp. 5539-5564.

M. Pouranvari, H.R. Asgari, S.M. Mosavizadeh, P.H. Marashi, and M. Goodarzi: Sci. Technol. Weld. Joining, 2007, vol. 12, pp. 217-225.

P. Marashi, M. Pouranvari, S.M.H. Sanaee, A. Abedi, S.H. Abootalebi, and M. Goodarzi: Mater. Sci. Technol., 2008, vol. 24, pp. 1506-1512.

X. Sun, E.V. Stephens, and M.A. Khaleel: Eng. Fail. Anal., 2008, vol. 15, pp. 356-367.

W. Tao, L.Q. Li, Y.B. Chen, and L. Wu: Sci. Technol. Weld. Joining, 2008, vol. 13, pp. 754-759.

M. Carboni and M. Annoni: Sci. Technol. Weld. Joining, 2011, vol. 16, pp. 116-125.

M. Pouranvari, S.P.H. Marashi, and D.S. Safanama: Mater. Sci. Eng., A, 2011, vol. 528, pp. 8344-8352.

M. Pouranvari, S.M. Mousavizadeh, S.P.H. Marashi, M. Goodarzi, and M. Ghorbani: Mater. Des., 2011, vol. 32, pp. 1390-1398.

D.S. Safanama, S.P.H. Marashi, and M. Pouranvari: Sci. Technol. Weld. Joining, 2012, vol. 17, pp. 288-294.

A. Shirdel, A. Khajeh, and M.M. Moshksar: Mater. Des., 2010, vol. 31, pp. 946-950.

S. Morattab, K. Ranjbar, and M. Reihanian: Mater. Sci. Eng., A, 2011, vol. 528, pp. 6912-6918.

F. Khakbaz and M. Kazeminezhad: J. Manuf. Processes, 2012, vol. 14, pp. 20-25.

ASTM standard E8M: Tension Testing of Metallic Materials. Annual Book of ASTM Standards, ASTM, West Conshohocken, 1998.

American Welding Society: ANSI/AWS/SAE/D8.9-99, Recommended Practices for Test Methods and Evaluation the Resistance Spot Welding Behavior of Automotive Sheet Steels, 1999.

B.H. Chang, M.V. Li, and Y. Zhou: Sci. Technol. Weld. Joining, 2001, vol. 6, pp. 273-280.

P. Podržaj, I. Polajnar, J. Diaci, and Z. Kari: Sci. Technol. Weld. Join., 2006, vol. 11, pp. 250–54.

H.T. Sun, X.M. Lai, Y.S. Zhang, and J. Shen: Sci. Technol. Weld. Joining, 2007, vol. 12, pp. 718-724.

A.N. Gerritsen and J.O. Linde: Physica, 1952, vol. 18, pp. 877-890.

J.O. Linde: Physica, 1958, vol. 24(Supplement 1), pp. S109–S117.

A. Vorobieva, A. Nikulin, A. Shikov, V. Pantsyrny, M. Polikarpova, N. Kozlenkova, E. Dergunova, E. Popova, and L. Rodionova: Physica C, 2001, vol. 354, pp. 371-374.

J.E. Gould, S.P. Khurana, and T. Li: Welding Journal, 2006, vol. 86, pp. 111-116.

H. Zhang and J. Senkara: Resistance Welding: Fundamentals and Applications, Teylor & Francis, Boca Raton, 2006.

M. Pouranvari and S.P.H. Marashi: Mater. Sci. Eng., A, 2011, vol. 528, pp. 8337-8343.

M. Eizadjou, H.D. Manesh, and K. Janghorban: J. Alloys Compd., 2009, vol. 474, pp. 406-415.

Acknowledgments

The authors wish to thank the research board of Sharif University of Technology for the financial support and the provision of the research facilities used in this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 14, 2013.

Rights and permissions

About this article

Cite this article

Khodabakhshi, F., Kazeminezhad, M. & Kokabi, A.H. On the Failure Behavior of Highly Cold Worked Low Carbon Steel Resistance Spot Welds. Metall Mater Trans A 45, 1376–1389 (2014). https://doi.org/10.1007/s11661-013-2074-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-013-2074-3