Abstract

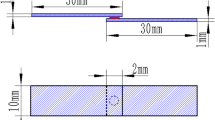

Brazing Inconel 625 (IN-625) using the copper foil has been investigated in this research. The brazed joint is composed of nanosized CrNi3 precipitates and Cr/Mo/Nb/Ni quaternary compound in the Cu/Ni-rich matrix. The copper filler 50 μm in thickness is enough for the joint filling. However, the application of Cu foil 100 μm in thickness has little effect on the shear strength of the brazed joint. The specimen brazed at 1433 K (1160 °C) for 1800 seconds demonstrates the best shear strength of 470 MPa, and its fractograph is dominated by ductile dimple fracture with sliding marks. Decreasing the brazing temperature slightly decreases the shear strength of the brazed joint due to the presence of a few isolated solidification shrinkage voids smaller than 15 μm. Increasing the brazing temperature, especially for the specimen brazed at 1473 K (1200 °C), significantly deteriorates the shear strength of the joint below 260 MPa because of coalescence of isothermal solidification shrinkage voids in the joint. The Cu foil demonstrates potential in brazing IN-625 for industrial application.

Similar content being viewed by others

References

J.R. Davis: ASM Handbook, vol. 2. Properties and Selection: Nonferrous Alloys and Special-Purpose Materials, ASM International, Materials Park, OH, 1990, pp. 428–45.

W.F. Smith: Structure and Properties of Engineering Alloys, 2nd ed., McGraw-Hill, New York, NY, 1993, pp. 279, 494–98.

K.P. Cooper, P. Slebodnick, and E.D. Thomas: Mater. Sci. Eng. A Struct., 1996, vol. 206, no. 1, pp. 138-49.

K.-H. Chang, J.-H. Huang, C.-B. Yan, T.-K. Yeh, F.-R. Chen, and J.-J. Kai: Prog. Nucl. Energy, 2012, vol. 57, pp. 20-31.

M. Montazeri and F.M. Ghaini: Mater. Charact., 2012, 67, pp. 65-73.

M. Zhong, H. Sun, W. Liu, X. Zhu, and J. He: Scripta Mater., 2005, vol. 53, no. 2, pp. 159-64.

S.M. Mousavizade, F.M. Ghaini, M.J. Torkamany, J. Sabbaghzadeh, and A. Abdollah-zadeh: Scripta Mater., 2009, vol. 60, no. 4, pp. 244-47.

A.T. Egbewande, R.A. Buckson, and O.A. Ojo: Mater. Charact., 2010, vol. 61, no. 5, pp. 569-74.

M.A. Arafin, M. Medraj, D.P. Turner, and P. Bocher: Mater. Sci. Eng. A-Struct., 2007, vol. 447 (1–2), pp. 125–33.

M. Reppich: Int. J. Therm. Sci., 1999, vol. 38, no. 11, pp. 999-1008.

M.M. Abu-Khader: Renew. Sust. Energ. Rev., 2012, vol. 16, no. 4, pp. 1883-91.

A. Munitz: J. Mater. Sci., 1995, vol. 30, no. 11, pp. 2901-910.

L.H. Chiu, W.C. Hsieh, and C.H. Wu: Mater. Sci. Eng. A-Struct., 2003, vol. 354 (1–2), pp. 82–91.

K.M. Deen, M.A. Virk, C.I. Haque, R. Ahmad, and I.H. Khan: Eng. Fail. Anal., 2010, vol. 17, no. 4, pp. 886-93.

O. Narivs’kyi: Mater. Sci., 2007, vol. 43 (1), pp. 124–32.

W.G. Moffatt: The Handbook of Binary Phase Diagrams, Genium Pub. Corp., Schenectady, NY, 1976, pp. 1266–68, 1442–46.

J.R. Davis: Nickel, Cobalt, and Their Alloys, ASM International, New York, NY, 2000, pp. 29-30.

T.B. Massalski: Binary Alloy Phase Diagrams, ASM International, New York, NY, 1990, pp. 1442-46.

T. Hodgkiess and D. Mantzavinos: Desalination, 1999, vol. 126 (1–3), pp. 129–37.

K.Z. Al-Subaie and T. Hodgkiess: Desalination, 2003, vol. 158 (1–3), pp. 43–50.

R.K. Shiue, S.K. Wu, and S.Y. Chen: Acta Mater., 2003, vol. 51, no. 7, pp. 1991-2004.

P. Villars: Pearson’s Handbook: Crystallographic Data for Intermetallic Phases, ASM International, Materials Park, OH, 1997, pp. 2706-07.

R.K. Roy, S. Singh, M.K. Gunjan, A.K. Panda, and A. Mitra: Fusion Eng. Des., 2011, vol. 86, pp. 452-55.

W.S. Chen and R.K. Shiue: ISIJ Int., 2012, vol. 52, no. 5, pp. 939-41.

W.S. Chen and R.K. Shiue: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 2177-82.

Acknowledgments

The authors gratefully acknowledge the financial support of this research by National Science Council, Taiwan, Republic of China (contract numbers NSC 99-2221-E-002-120-MY3 and NSC 102-2221-E-002-148).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 30, 2013.

Rights and permissions

About this article

Cite this article

Chen, WS., Wang, CY. & Shiue, RK. Brazing Inconel 625 Using the Copper Foil. Metall Mater Trans A 44, 5724–5731 (2013). https://doi.org/10.1007/s11661-013-1954-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-013-1954-x