Abstract

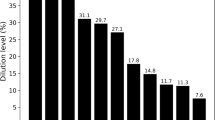

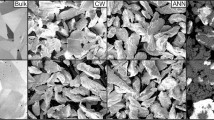

In order to establish more reliable formulae for calculating stacking fault energies (SFE) from the chemical compositions of austenitic stainless steels, SFE values were measured for 54 laboratory-melted heats and 2 commercial heats. The results were checked against those of a first-principle, atomistic calculation approach. More than ~20,000 data points for the width and angle of the Burgers vectors were determined from dark-field images of isolated extended dislocations in 56 heats of austenitic stainless steel using weak electron beams with g-3g diffraction conditions. Based on these numerous observations and on fundamental thermodynamic analyses, it is concluded that the SFE values for austenitic stainless steels are changed not only by chemical composition but also by heat treatment. In this paper, new formulae for calculating SFE values from the chemical compositions in three different heat treatment conditions have been proposed for austenitic stainless steels within given limited chemical composition ranges. In these formulae, the SFE values are calculated from the nickel, chromium, molybdenum, silicon, manganese, nitrogen, and carbon contents for the each heat treatment condition. The three heat treatment conditions studied were water cooling after solution heat treating (SHTWC), furnace cooling after solution heat treating, and aging after SHTWC.

Similar content being viewed by others

References

H.C. Rogers (1967) Ductility. American Society for Metals, Metals Park, OH, pp. 55.

R.E. Schramm, R.P. Reed: Metall. Trans. A, 1975, vol. 6A, pp. 1345 -1351.

W. Karlsen, G. Diego, B. Devrient (2010) J. Nucl Mater 406:138–51.

H. Suzuki: Sci. Rep. Res. Inst. Tohoku Univ., 1952, vol. A4, pp. 455.

H. Suzuki: Dislocations and Mechanical Properties of Crystals, John Wiley & Sons, Inc., New York, 1957, pp. 361–90.

R.M. Latanision, A.W. Ruff, Jr. (1971) Metall. Trans. 2:505–09.

C.G. Rhodes, A.W. Thompson: Metall. Trans. A, 1977, vol. 8A, pp. 1901–06.

P.J. Brofman, G.S. Ansell: Metall. Trans. A, 1978, vol. 9A, pp. 879–90.

E.B. Pickering (1984). Stainless Steel ‘84. The Institute of Metals, London, pp. 2–28.

R.E. Stoltz, J.B. Vandersande: Metall. Trans. A, 1980, vol. 11A, pp. 1033–37.

D. Dulieu, J. Nutting: Metallurgical developments in high-alloy steels, Special report no.86. London, The Iron and Steel Institute, 1964, pp.140.

L. Vitos, J-O. Nilsson, B. Johansson: Acta Materialia, 2006, vol. 54, pp. 3821–26.

K.H. Lo, C.H. Shek, J.K.L. Lai: Mater. Sci. Eng. R, 2009, vol. 65, pp. 39–104.

F. Pettinari, J. Douin, G. Saada, P. Caron, A. Coujon, N. Clement: Mater. Sci. Eng., 2002, vol. A325, pp. 511–19.

E.R. Gilbert, J.P. Foster: J. Nucl. Mater., 2002, vol. 300, pp. 321–28.

S. Kibey, J.B Liu, M.J. Curtis, D.D. Johnson, H. Sehitoglu: Acta Materialia, 2006, vol. 54, pp. 2991–3001.

Yu. N. Petrov (2003) Z. Metallkd 94:1012–16.

V. Gavriljuk, Yu. Petrov, B. Shanina (2006) Scripta Mater. 55, pp. 537–40.

D.J.H. Cockayne, M.L. Jenkins, I.L.F. Ray: Philosophical Magazine, 1971, vol. 24, pp. 1383–92.

J.P. Perdew, J.A. Chevary, S.H. Vosko, K.A. Jackson, M.R. Pederson, D.J. Singh, C. Fiolhais: Phys. Rev. B, 1992, vol. 46, pp. 6671–87.

A.P. Midownik (1978) CALPHAD 2:207–26.

A. Dick, T. Hickel and J. Neugebauer (2009) Steel Res. Int. 80:603–08.

Acknowledgments

A part of this study was performed as a section of the collaboration research program which was financially supported by the Tokyo Electric Power Company. Another part of this study was supported by JSPS KAKENHI Grant Number 22360396. The authors would like to acknowledge their financial support. For the calculation of SFE values, Associate Professor M. Watanabe gave us excellent suggestions. The authors would like to acknowledge his advice.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 17, 2013.

Rights and permissions

About this article

Cite this article

Yonezawa, T., Suzuki, K., Ooki, S. et al. The Effect of Chemical Composition and Heat Treatment Conditions on Stacking Fault Energy for Fe-Cr-Ni Austenitic Stainless Steel. Metall Mater Trans A 44, 5884–5896 (2013). https://doi.org/10.1007/s11661-013-1943-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-013-1943-0