Abstract

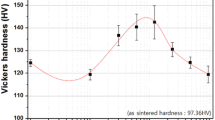

The hypereutectic Al-Si alloys constitute an important family of alloys because of their excellent wear resistance and low thermal expansion. However, the optimal microstructure and hence the optimal service performance of these alloys cannot be achieved by the conventional melt treatments used in industry today, because of the chemical incompatibility between the primary-Si refiners and the eutectic-Si modifiers used in microstructure control. The current study aimed at using ultrasonic vibrations to improve the microstructure and the properties of these alloys. The results of the current study showed that for the B390 Al-Si alloy (i) the ultrasonic treatment has potential refining effect on the primary Si and Fe intermetallic phases, (ii) the primary Si particles become finer as the pouring temperature decreases from 1033 K (760 °C) to 938 K (665 °C), (iii) pouring and ultrasonic treatment at temperatures below the start of primary Si precipitation result in the coexistence of large and fine Si particles in microstructure, (iv) phosphorous additions of 50 ppm did not show any substantial effect in the ultrasonically treated ingots, (v) ultrasonic-treated samples have uniform hardness over the surface while the untreated samples show large scattering (high standard deviation) in hardness levels and (vi) ultrasonic-treated samples showed better wear resistance in the absence of phosphorous.

Similar content being viewed by others

References

G.K.Sigworth: AFS Trans., 1983, vol. 91, pp. 7-15.

J. E. Hatch (ed.): Aluminum: Properties and Physical Metallurgy, American Society for Metals, Metals Park, OH, 1984.

J. Gruzleski and B. Closset: The Treatment of Liquid Aluminum-silicon Alloys, The American Foundrymen Society, Des Plaines, 1990.

I.G. Brodova, P.S. Popel and G.I. Eskin: Liquid Metal Processing: Applications to Aluminum Alloy Production, Taylor & Francis, London, 2002.

W. Khalifa, Y. Tsunekawa, M. Okumiya: AFS Trans., 2010, vol. 118, pp. 91–8.

W. Khalifa, Y. Tsunekawa, M. Okumiya: Int. J. Cast. Met. Res., 2008, vol. 21, pp. 129–134.

Li Xin-tao, Li Ting-ju, Li Xi-meng, Jin Jun-ze: Ultrason. Sonochem., 2006, vol. 13, pp. 121–25.

Y. Tsunekawa, K. Taga, Y. Fukui, and M. Okumiya: Mater. Sci. Forum, 2010, vols. 638–642, pp. 362–67.

J.I. Youn, B.I. Kang, D.G. Ko, and Y.J. Kim: Int. J. Cast Met. Res., 2008, vol. 21, pp. 135–38.

V.O. Abramov, O.V. Abramov, B.B. Straumal, and W. Gust: Mater. Des., 1997, vol. 18, pp. 323–26.

K. Oda, S. Komarov, Y. Ishiwata, T. Tsuchida, and I. Okamoto: 7th High Quality Die Casting Meeting, Japan, 2007.

H. Puga, S. Costa, J. Barbosa, S. Ribeiro, M. Prokic: J. Mater. Process. Technol. 2011, vol. 211 1729–35.

L. Backreud, G. Chai, and J. Tamminen: Solidification Characteristics of Aluminum Alloys, AFS/Akanaluminium, Stokholm, 1990.

G.I. Eskin: Ultrasonic Treatment of Light Alloy Melts, Gordon &Breach, Amsterdam, 1998.

X. Jian, H. Xua, T.T. Meeka, and Q. Hanb: Mater. Lett., 2005, vol. 59, pp. 190–93.

V. Abramov, O. Abramov, V. Bulgakov, and F. Sommer: Mater. Lett., 1998, vol. 37, pp. 27–34.

M. Faraji, D.G. Eskin, and L. Katgerman: Int. Foundry Res., 2010, vol. 62, pp. 20–23.

X. Jian, T.T. Meek, and Q. Han: Scripta Mater. 2006, vol. 54, pp. 893–96.

H. Kattoh, A. Hashimoto, S. Kitaoka, M. Kattoh, and M. Shioda: J. Jpn. Foundry Soc., 2002, vol. 52, pp. 18–23.

G.I. Eskin: Ultrason. Sonochem., 2001, vol. 8, pp. 319–25.

T.V. Atamanenko, D.G. Eskin, L. Zhang, and L. Katgerman: Metall. Mater. Trans. A, 2010, vol. 41A, pp. 2056–66.

A.T. Alpas, and J. Zhang: Metall. Mater. Trans. A, 1994, vol. 25A, pp. 969–81.

C.Y.Yang, S.L.Lee, C.K. Lee, and J.C. Lin: Wear, 2006, vol. 261, 1348–58.

H. Sato,T. Murase, T. Fujii, S. Onaka, Y. Watanabe, and M. Kato: Acta Mater., 2008, vol. 56, pp. 4549–58.

Acknowledgments

The authors would like to thank the group of “Materials Processing Laboratory,” Toyota Technological Institute- Japan, where the UST experiments were performed, and the “Foundry Technology Division,” Central Metallurgical R&D Institute-Egypt, where some microstructural studies and wear tests were performed.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 10, 2012.

Rights and permissions

About this article

Cite this article

Khalifa, W., El-Hadad, S. & Tsunekawa, Y. Microstructure and Wear Behavior of Solidification Sonoprocessed B390 Hypereutectic Al-Si Alloy. Metall Mater Trans A 44, 5817–5824 (2013). https://doi.org/10.1007/s11661-013-1936-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-013-1936-z