Abstract

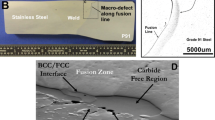

The large circumferential multipass dissimilar weld between 20MND5 steel and Z2CND18-12NS stainless steel welded with FM52 filler material was investigated in terms of the diluted composition, the grain boundary precipitation, and the ductility-dip cracking (DDC) susceptibility of the weld. The diluted composition of the weld is composed of 37 to 47 pct Ni, 21 to 24 pct Cr, and 28 to 40 pct Fe, which are inhomogeneous along the depth and over the width of the deep weld. The carbon content has a distribution in the region of the surface weld from a high level (~0.20 pct) in the zone near 20MND5 steel to a normal level (~0.03 pct) in the zone near Z2CND18-12NS stainless steel. The carbon distribution is corresponding to the grain boundary carbides. The minimum threshold strains for DDC occur in the temperature range of 1223 K to 1323 K (950 °C to 1050 °C), which are 0.5, 0.35, and 0.4 pct for the root weld, middle region, and the surface weld, respectively. The dissimilar weld has the largest susceptibility to the DDC compared to the filler metal 52 and the Inconel 690.

Similar content being viewed by others

References

C. Jang, J. Lee, J.S. Kim and T.E. Jin: Int. J. Pressure Vessels Pip., 2008, vol. 85, pp. 635–46.

N. Arivazhagan, S. Singh, S. Prakash and G.M. Reddy: Mater. Des., 2011, vol. 32, pp. 3036–50.

T. Ogawa, M. Itatani, T. Saito, T. Hayashi, C. Narazaki and K. Tsuchihashi: Int. J. Pressure Vessels Pip., 2012, vol. 90/91, pp. 61–8.

H. Naffakh, M. Shamanian and F. Ashrafizadeh: J. Mater. Process. Technol., 2009, vol. 209, pp. 3628–39.

Y. Hu, X. He, G. Yu, Z. Ge, C. Zheng and W. Ning: Appl. Surf. Sci., 2012, vol. 258, pp. 5914–22.

M. Sireesha, S.K. Albert, V. Shankar and S. Sundaresan: J. Nucl. Mater., 2000, vol. 279, pp. 65–76.

B. Grönwall, L. Ljungberg, W. Hübner and W. Stuart: Nucl. Eng. Des., 1967, vol. 6, pp. 383–90.

G. Frédérick and P. Hernalsteen: Int. J. Pressure Vessels Pip., 1986, vol. 25, pp. 47–67.

T. Magnin, D. Noël and R. Rios: Mater. Sci. Eng. A, 1994, vol. 177, pp. L11–L14.

J.J. Kai, G.P. Yu, C.H. Tsai, M.N. Liu and S.C. Yao: Metall. Trans. A, 1989, vol. 20, pp. 2057–67.

K. Stiller, J. Nilsson and K. Norring: Metall. Mater. Trans. A, 1996, vol. 27, pp. 327–41.

H.P. Kim, S.S. Hwang, Y.S. Lim, I.H. Kuk and J.S. Kim: Met. Mater. Int., 2001, vol. 7, pp. 55–9.

M.G. Collins and J.C. Lippold: Weld. J., 2003, vol. 82, pp. 288–95.

A.J Ramirez and J.C. Lippold: Mater. Sci. Eng. A, 2004, vol. 380, pp. 245–58.

V.R. Dave, M.J. Cola, M. Kumar, A.J. Schwartz and G.N.A. Hussen: Weld. J., 2004, vol. 83, pp.1–5s.

F.F. Noecker, and J.N. Dupont: Weld. J., 2009, vol. 88, pp. 7–20.

A.J. Ramirez and J.C. Lippold: Mater. Sci. Eng. A, 2004, vol. 380, pp. 259–71.

N.E. Nissley and J.C. Lippold: Weld. J., 2003, vol. 82, pp. 355–64.

N.E. Nissley and J.C. Lippold: Weld. J., 2008, vol. 87, pp. 257–64.

H. Baker: ASM Handbook, Vol. 03 Alloy Phase Diagrams. ASM International, Materials Park, 1992, pp. 343–344.

T.Y. Kuo and H.T. Lee: Mater. Sci. Eng. A, 2002, vol. 338, pp. 202–12.

T.M. Angeliu and G.S. Was: Metall. Trans. A, 1990, vol. 21A, pp. 2097–107.

Y.S. Lim, J.S. Kim, H.P. Kim and H.D. Cho: J. Nucl. Mater., 2004, vol. 335, pp. 108–14.

H.U. Hong, B.S. Rho and S.W. Nam: Mater. Sci. Eng. A, 2001, vol. 318, pp. 285–92.

E.L. Hall and C.L. Briant: Metall. Trans. A, 1985, vol. 16, pp. 1225–36.

H.T. Lee and J. Lin Wu: Corrosion Sci., 2009, vol. 51, pp. 439–45.

T.P.S. Gill, M. Vijayalakshmi, P. Rodrguez and K.A. Padmanabhan: Metall. Trans. A, 1989, vol. 20, pp. 1115–24.

A.A. Tavassoli and G. Colombe: Metall. Trans. A, 1978, vol. 9, pp. 1203–11.

A.J. Ramirez, J.W. Sowards and J.C. Lippold: J. Mater. Process. Technol., 2006, vol. 179, pp. 212–8.

Y.H. Kim, D.J. Lee, J.C. Byun, K.H. Jung, J.I. Kim, H.J. Lee, Y.T. Shin, S.H. Kim and H.W. Lee: Mater. Des., 2011, vol. 32, pp. 330–6.

H. Li, S. Xia, B. Zhou and W. Liu: Mater. Charact., 2012, vol. 66, pp. 68–74.

S.D. Kiser, R. Zhang, and B.A. Baker: ASM Proc. 8th Int. Conf: Trends Weld. Res., 2009, pp. 639–44.

M. Pouranvari, A. Ekrami and A.H. Kokabi: J. Alloy. Compd., 2013, vol.563, pp. 143–9.

W. Lin, J.C. Lippold and W.A. Baeslack: Weld. J., 1993, vol. 71, pp. 135s–53s.

H.T. Lee and J.L. Wu: Corrosion Sci., 2010, vol. 52, pp. 1545–50.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 24, 2013.

Rights and permissions

About this article

Cite this article

Qin, R., Duan, Z. & He, G. Microstructure and Ductility-Dip Cracking Susceptibility of Circumferential Multipass Dissimilar Weld Between 20MND5 and Z2CND18-12NS with Ni-Base Filler Metal 52. Metall Mater Trans A 44, 4661–4670 (2013). https://doi.org/10.1007/s11661-013-1833-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-013-1833-5