Abstract

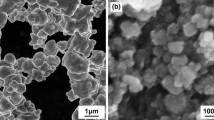

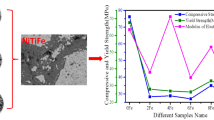

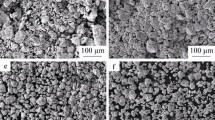

In the current study, Ni50Fe50 alloy powders were prepared using a high-energy planetary ball mill. The effects of TiC addition (0, 5, 10, 20, and 30 wt pct) and milling time on the sequence of alloy formation, the microstructure, and microhardness of the product were studied. The structure of solid solution phase, the lattice parameter, lattice strain, and grain size were identified by X-ray diffraction analysis. The correlation between the apparent densities and the milling time is explained by the morphologic evolution of the powder particles occurring during the high-energy milling process. The powder morphology was examined using scanning electron microscopy. It was found that FCC γ (Fe–Ni) solid solution was formed after 10 hours of milling, and this time was reduced to 7 hours when TiC was added. Therefore, brittle particles (TiC) accelerate the milling process by increasing crystal defects leading to a shorter diffusion path. Observations of polished cross section showed uniform distribution of the reinforcement particles. The apparent density increases with the increasing TiC content. It was also found that the higher TiC amount leads to larger lattice parameter, higher internal strain, and lower grain size of the alloy.

Similar content being viewed by others

References

K. Lin, T. Yang, and W. Tsai: Mater. Sci. Eng. A., 2006, vol. 416, pp. 226–31.

M.J. Donachie and S.J. Donachie: in Superalloys A Technical Guide, 2nd ed, Chapt. 1, ASM International, Materials Park, 2002, pp. 1–9.

S.C. Tjong and K.C. Lau: Mater. Lett., 1999, vol. 41, pp. 2415–19.

N. Durlu: J. Eur. Ceram. Soc., 1999, vol. 19, pp. 2415–19.

M. Sherif El-Eskandarany: Mechanical Alloying for Fabrication of Advanced Engineering Materials, Noyes Publications/William Andrew Publishing, New York, 2001, pp. 1–5.

L. Lu and M.O. Lai: in Mechanical Alloying, Kluwer Academic Publisher, Boston, 1998, p. 26.

C. Suryanarayana: Prog. Mater. Sci., 2001, vol. 46, pp. 1–184.

J.B. Fogagnolo, M.H. Robert, and J.M. Torralba: Mater. Sci. Eng. A., 2006, vol. 426, pp. 85–94.

E. Lifshin: in X-ray Characterization of Materials, Wiley-VCH, New York, 1999.

E. Jartych, J.K. Zurawicz, D. Oleszak, and M. Pekala: Nanostruct. Mater., 1999, vol. 12, pp. 927–30.

A. Guittoum, A. Layadi, A. Bourzami, H. Tafatc, N. Souami, S. Boutarfaia and D. Lacour: J. Magn. Magn. Mater., 2008, vol. 320, pp. 1385–92.

S.D. Kaloshkin, V.V. Tcherdyntsev, I.A. Tomilin, Yu.V. Baldokhin and E.V. Shelekhov: Phys. Rev. B: Condens. Matter., 2001, vol. 299, pp. 236–41.

Yu.V. Baldokhin, V.V. Tcherdyntsev, S.D. Khaloshkin, G.A. Kochetov and Yu. A. Pustov: J. Magn. Magn. Mater. 1999, vol. 203, pp. 313–15.

J. Benjamin: Annu. Rev. Mater. Sci., 1983, vol. 13, 279–300.

D. Oleszak and P.H. Shingu: Mater. Sci. Eng. A., 1994, vol. 181–182, pp. 1217–21.

S. Bid and S.K. Pradhan: Mater. Chem. Phys., 2004, vol. 84, pp. 291–01.

V.V. Tcherdyntsev, S.D. Kaloshkin, I.A. Tomilin, E.V. Shelekhov, and Yu.V. Baldokhin: Nanostruct. Mater., 1999, vol. 12, pp. 139–42.

A. Djekoun, B. Bouzabata, A. Otmani, and J.M. Greneche: Catal. Today, 2004, vol. 89, pp. 319–23.

R. M. Davis, B. McDermott, and C. C. Koch: Metall. Trans. A, 1988, vol. 19, pp. 2867–74.

G.M. Candido, V. Guido, G. Silva and K.R. Cardoso: Mater. Sci. Forum, 2010, vol. 660–661, pp. 317–24.

A. Alizadeh, E. Taheri-Nassaj, and H.R. Baharvandi: Bull. Mater. Sci., 2011, vol. 34, pp. 1039–48.

J.B. Fogagnolo, F. Velasco, M.H. Robert, and J.M. Torralba: Mater. Sci. Eng. A, 2003, vol. 342, pp. 131–43.

S. Kamrani, R. Riedel, S.M. Seyed Reihani, and H.J. Kleebe: J. Compos. Mater., 2010, vol. 44, pp. 312–26.

S.S. Razavi Tousi, R. Yazdani Rad, E. Salahi, and M. Razavi: Mater. Sci., 2009, vol. 27, pp. 875–84.

D.R. Amador and J.M. Torralba: J. Mater. Process. Technol., 2003, vol. 143–144, vol. 776–78.

Acknowledgments

The authors would like to thank the Office of the Research Affairs of Islamic Azad University, Najafabad Branch, for financial support of this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted November 11, 2012.

Rights and permissions

About this article

Cite this article

Shirani Bidabadi, M.H., Saidi, A., Kasiri, M. et al. Microstructures and Properties of Nanocrystalline NiFe Alloy With and Without Particulate TiC Reinforcement by Mechanical Alloying. Metall Mater Trans A 44, 4800–4808 (2013). https://doi.org/10.1007/s11661-013-1822-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-013-1822-8