Abstract

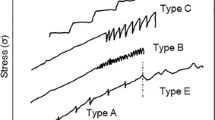

Transformation-induced plasticity (TRIP) behavior was studied in steel with the composition Fe-0.07C-2.85Si-15.3Mn-2.4Al-0.017N that exhibited two TRIP mechanisms. The initial microstructure consisted of both ε- and α-martensites with 27 pct retained austenite. TRIP behavior in the first 5 pct strain was predominately austenite transforming to ε-martensite (Stage I), but upon saturation of Stage I, the ε-martensite transformed to α-martensite (Stage II). Alloy segregation also affected the TRIP behavior with alloy-rich regions producing TRIP just prior to necking. This behavior was explained by first-principles calculations which revealed that aluminum significantly affected the stacking fault energy in Fe-Mn-Al-C steels by decreasing the unstable stacking fault energy and promoting easy nucleation of ε-martensite. The addition of aluminum also raised the intrinsic stacking fault energy and caused the ε-martensite to be unstable and transform to α-martensite under further deformation. The two-stage TRIP behavior produced a high strain hardening exponent of 1.4 and led to an ultimate tensile strength of 1165 MPa and elongation to failure of 35 pct.

Similar content being viewed by others

References

J. Fekete and J. Hall: NIST Internal Report 6668, National Institute of Standards and Technology, Washington, DC, May 2012.

D.K. Matlock and J.G. Speer: Proceedings of the 3 rd Int. Conf. on Structural Steels, H.C. Lee, ed., The Korean Institute of Metals and Materials, Seoul, Korea, 2006, pp. 774–81.

L. Bracke, L. Kestens, and J. Penning: Scripta Mater., 2007, vol. 57, pp. 385–88.

K. Spencer, J.D. Embury, K.T. Conlon, M. Veron, and Y. Brechet: Mater. Sci. Eng. A, 2004, vols. 387–389, pp. 873–81.

E.Yang, H. Zurob, and J. McDermid: Proc. MS&T, 2010, pp. 1914–25.

S. Takaki, T. Furuya, and Y. Tokunaga: ISIJ Int., 1990, vol. 30, pp. 632–38.

K. Sipos, L. Remy, and A. Pineau: Metall. Trans. A, 1976, vol. 7A, pp. 857–64.

X. Sun, K.S. Choi, A. Soulami, W.N. Liu, and M.A. Khaleel: Mater. Sci. Eng., 2009, vol. 526, pp. 140–49.

B. Jiang, X. Qi, S. Yang, W. Zhou, and T.Y. Hsu: Acta Mater., 1998, vol. 46(2), pp. 501–10.

J.P. Hirth: Metall. Trans., 1970, vol. 1, pp. 2367–74.

O. Grässel, G. Frommeyer, C. Derder, and H. Hofmann: J. Phys. IV France, 1997, vol. 7, pp. C5-383–88.

Y-K. Lee and C-S. Choi: Metall. Mater. Trans. A, 2000, vol. 31A, pp. 355–60.

S. Allain, J.-P. Chateau, O. Bouaziz, S. Migot and N. Guelton: Mater. Sci. Eng., 2004, vols. 387–389A, pp. 158–62.

H. Schumann: J. Kristall Tchnik, 1974, vol. 10, pp. 1141–50.

P. Yu Volosevich, V.N. Grindnev, and Y.N. Petrov: Phys. Met. Metallogr., 1976, vol. 42, pp. 126–30.

T. Suzuki, H. Kojima, K. Suzuki, T. Hashimoto, and M. Ichihara: Acta Metall., 1977, vol. 25, pp. 1151–62.

J.W. Brooks, M.H. Loretto, and R.E. Smallman: Acta Metall., 1979, vol. 27, pp. 1839–47.

J.W. Brooks, M.H. Loretto, and R.E. Smallman: Acta Metall., 1979, vol. 27, no. 12, pp. 1829–38.

G.B. Olson and M. Cohen: Metall. Trans. A, 1975, vol. 6A, pp. 791–95.

T. Suzuki, H. Kojima, K. Suzuki, T Hashimot, and M Ichihara: Acta Metall., 1977, vol. 25, no. 10, pp. 1151–62.

F. Lecroisey and A. Pineau: Metall. Trans., 1972, vol. 3, pp. 387–96.

C. Zener: Trans. TMS-AIME, 1946, vol. 167, pp. 513–34.

L. Kaufman and M. Cohen: Trans. TMS-AIME, 1956, vol. 206, pp. 1393–01.

L.E. Murr, K.P. Staudhammer, and S.S. Hecker: Metall. Trans. A, 1982, vol. 13A, pp. 627–35.

J. Talonen and H. Hanninen: Acta Mater., 2007, vol. 55, pp. 6108–18.

G. Frommeyer, U. Brux, and P. Neumann: ISIJ Int., 2003, vol. 77(3), pp. 438–46.

M. Cai, H. Ding, Z. Tang, H. Lee, and Y. Lee: Steel Res. Int., 2011, vol. 82(3), pp. 242–48.

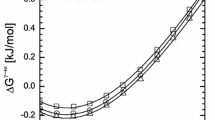

N.I. Medvedeva, M.S. Park, D.C. Van Aken, and J.E. Medvedeva: arXiv:1208.0310v1 [cond-mat.mtrl-sci], 2012.

ASTM E 8-08, ASTM International, USA, 2008.

A.K. De, D.C. Murdock, M.C. Mataya, J.G. Speer, and D.K. Matlock: Scripta Mater., 2004, vol. 50, pp. 1445–49.

Thermfact and FTT-Technologies, FactSage 6.2, Aachen, Germany, 2009.

T.S.Byun: Acta Mater., 2003, vol. 51, pp. 3063–71 .

D.A. Mirzayev, V.M. Schastlivtsev, and A.G. Tayzetdinova: Phys. Met. Metall., 1987, vol. 63, pp. 99–105.

M. Palumbo: CALPHAD, 2008, vol. 32, pp. 693–08.

Payson and Savage: Trans. ASM, 1944, vol. 33, pp. 261–75.

K. Ishida: J. Alloys Compd., 1995, vol. 220, pp. 126–31.

M. Gomez: ISIJ Int., 2009, vol. 49, no. 2, pp. 302–11.

Y.G. Kimand: Key Eng. Mater., 1993, vols. 84–85, pp. 461–71.

Acknowledgments

This work was supported in part by the National Science Foundation (NSF) and the Department of Energy under contract CMMI 0726888. The authors gratefully acknowledge the support of the Graduate Center for Materials Research and in particular Dr. Eric Bohannen for help with X-ray diffraction. Meghan McGrath was supported by a Department of Education GAANN fellowship under contract P200A0900048.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 3, 2012.

Rights and permissions

About this article

Cite this article

McGrath, M.C., Van Aken, D.C., Medvedeva, N.I. et al. Work Hardening Behavior in Steel with Multiple TRIP Mechanisms. Metall Mater Trans A 44, 4634–4643 (2013). https://doi.org/10.1007/s11661-013-1820-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-013-1820-x