Abstract

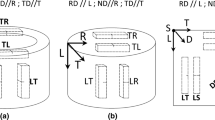

In this article, tensile tests as well as LS and LT notched Charpy impact tests were performed at the temperature range between 77 K (−196 °C) and 473 K (200 °C) on an oxide-dispersion-strengthened (ODS) Fe20Cr6Al0.5Y2O3 hot-rolled tube. The absorbed energy values in the range of high temperatures of LS notched specimens are considerably higher than those of LT notched specimens; however, such values tend to converge as temperature increases. Ductile fracture on the normal planes to RD with delaminations parallel to the tube surface was observed in the temperature range between room temperature (RT) and 473 K (200 °C). Delaminations of crack divider type were observed in LT specimens, whereas delaminations of crack arrester type were observed in LS specimens. The yttria particles in the grain boundaries and the transverse plastic anisotropy are the possible reasons why the delaminations were parallel to the tube surface.

Similar content being viewed by others

References

S. Ukai and M. Fujiwara: J. Nucl. Mater., 2002, vols. 307-311, pp. 749-57.

S. Jitsukawa, A. Kimura, A. Kohyama, R.L. Klueh, A.A. Tavassoli, B. van der Schaaf, G.R. Odette, J.W. Rensman, M. Victoria, and C. Petersen: J. Nucl. Mater., 2004, vols. 329-333, pp. 39-46.

M.M. Abu-Khader: Progr. Nucl. Energ., 2009, vol. 51, pp. 225-35.

G.S. Bauer: J. Nucl. Mater., 2010, vol. 398, pp. 19-27.

J. Chen, M.A. Pouchon, A. Kimura, P. Jung, and W. Hoffelner: J. Nucl. Mater., 2009, vols. 386-388, pp. 143-6.

S. Ukai, M. Harada, H. Okada, M. Inoue, S. Nomura, S. Shikakura, T. Nishida, M. Fujiwara, and K. Asabe: J. Nucl. Mater., 1993, vol. 204, pp. 74-80.

M.J. Alinger, G.R. Odette, and G.E. Lucas: J. Nucl. Mater., 2002, vols. 307-311, pp. 484-9.

R. Kasada, N. Toda, K. Yutani, H.S. Cho, H. Kishimoto, and A. Kimura: J. Nucl. Mater., 2007, vols. 367-370, pp. 222-8.

C. Capdevila, U. Miller, H. Jelenak, and H. Bhadeshia: Mater. Sci. Eng. A, 2001, vol. 316, pp. 161-5.

C. Capdevila, F.G. Caballero, and C.G. de Andres: Mater. Sci. Technol., 2003, vol. 19, pp. 581-6.

M. Klimiankou, R. Lindau, A. Moslang, and J. Schroder: Powder Metall., 2005, vol. 48, pp. 277-87.

M. Klimiankou, R. Lindau, and A. Möslang: J. Crystal Growth, 2003, vol. 249, pp. 381-7.

G. Pimentel, I. Toda-Caraballo, J. Chao, and C. Capdevila: J. Mater. Sci., 2012, vol. 47, pp. 5605-16.

N. Tsuji, S. Okuno, Y. Koizumi, and Y. Minamino: Mater. Trans., 2004, vol. 45, pp. 2272-81.

R. Song, D. Ponge, and D. Raabe: Acta Mater., 2005, vol. 53, pp. 4881-92.

Y. Kimura, T. Inoue, F. Yin, and K. Tsuzaki: ISIJ Int., 2010, vol. 50, pp. 152-61.

J.D. Embury, N.J. Petch, A.E. Wraith, and E.S. Wright: Trans. Metall. Soc. AIME, 1967, vol. 239, pp. 114-32.

D.W. Kum, T. Oyama, J. Wadsworth, and O.D. Sherby: J. Mech. Phys., 1983, vol. 31, pp. 173-86.

Y. Kimura: Bull. Iron Steel Inst. Jpn., 2009, vol. 14, p. 154.

R. Hill: The Mathematical Theory of Plasticity, The Clarendon Press, Oxford, U.K., 1950, p. 254.

P. Brozzo and G. Buzzichelli: Scripta Metall., 1976, vol. 10, pp. 235-40.

C.M. Yen and C.A. Stickels: Metall. Trans., 1970, vol. 1, pp. 3037-47.

W. Zhou and N.L. Loh: Scripta Mater., 1996, vol. 34, pp. 633-9.

N.Y. Zolotorevsky and N.Y. Krivonosova: Mater. Sci. Eng. A, 1996, vol. 205, pp. 239-46.

E.C. Oliver, M.R. Daymond, and P.J. Withers: Acta Mater., 2004, vol. 52, pp. 1937-51.

J. Gil Sevillano, J. Alkorta, D. González, S. Van Petegem, U. Stuhr, and H. Van Swygenhoven: Adv. Eng. Mater., 2008, vol. 10, pp. 951-4.

W.F. Hosford: The Mechanics of Crystals and Textured Polycrystals, Oxford University Press, New York, NY, 1993, p. 152.

M. Taguchi, H. Sumitomo, R. Ishibashi, and Y. Aono: Mater. Trans., 2008, vol. 49, pp. 1303-10.

M. Pozuelo, F. Carreno, and O.A. Ruano: Compos. Sci. Technol., 2006, vol. 66, pp. 2671-6.

Acknowledgments

PM 2000 is a trademark of Plansee GmbH. The authors acknowledge the financial support of the Spanish Ministerio de Economia e Innovación (MINECO) in the form of a Coordinate Project in the Energy Area of Plan Nacional 2009 (ENE2009-13766-C04-01). G.P. acknowledges MINECO for financial support in the form of PhD Research Grant (FPI). This research was supported by ORNL’s Shared Research Equipment (SHaRE) User Facility, which is sponsored by the Office of Basic Energy Sciences, U.S. Department of Energy.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 5, 2012.

Rights and permissions

About this article

Cite this article

Chao, J., Capdevila, C., Serrano, M. et al. Notch Impact Behavior of Oxide-Dispersion-Strengthened (ODS) Fe20Cr5Al Alloy. Metall Mater Trans A 44, 4581–4594 (2013). https://doi.org/10.1007/s11661-013-1815-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-013-1815-7