Abstract

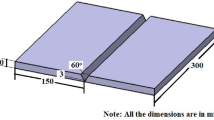

In the present investigation, an attempt has been made to study the effect of capping front layers on the ballistic performance of shielded metal arc-welded armor steel joints which were fabricated with a chromium carbide-rich hardfaced middle layer on the buttered/beveled edge. Two different capping front layer materials were chosen for achieving better ballistic performance, namely, low hydrogen ferritic (LHF) and austenitic stainless steel (SS) fillers. On the other hand, the bottom layers are welded with SS filler for both joints. The consequent sandwiched joint served the dual purpose of weld integrity and penetration resistance of the bullet. It is observed that the penetration resistance is due to the high hardness of the hardfacing layer on the one hand and the energy-absorbing capacity of the soft backing SS weld deposits on the other hand. The complementary effect of layers successfully provided resistance to the projectile penetration. On a comparative analysis, the joint fabricated using the LHF filler capping front layer offered superior ballistic performance with respect to depth of penetration. This is mainly due to the presence of acicular ferrite along the bainitic structure in the LHF capping front layer, which caused a shallow hardness gradient along the weld center line.

Similar content being viewed by others

References

F. Ade (1991) Weld. J. 70:53–54.

G. Madhusudhan Reddy and T. Mohandas (1996) J. Mater. Process. Technol.. 57:23–30.

G. Madhusudhan Reddy, T. Mohandas and G.R.N. Tagore (1995) J. Mater. Process. Technol., 49:213–28.

G. Madhusudhan Reddy, T. Mohandas, K. Papukutty (1999) J. Impact. Eng, 22:775–91.

Seong-Hun Choo, Eung-Ryul Baek and Sunghak Lee: Metall. Mater. Trans. A, 1996, Vol. 27A, pp. 3335-40

P.K. Jena, K. Ramanjeneyulu, K. Siva Kumar, T. Balakrishna Bhat: Mater. Des., 2009, Vol. 30 issue (6), pp. 1922-29

M.Balakrishnan, V.Balasubramanian, G.Madhusudhan Reddy and K.Sivakumar: Mat.Des, 2011, Vol. 32, pp. 469–79

G.Magudeeswaran, V.Balasubramanian, T.S.Balasubramanian and G. Madhusudhan Reddy: J. Iron Steel Res. Int, 2008, Vol. 15 issue (6), pp. 87-94

G. Magudeeswaran, V. Balasubramanian, T.S. Balasubramanian and G. Madhusudhan Reddy: Sci. Technol. Weld. Join., 2008, Vol. 13 issue 2, pp. 97-105.

S. Atamert and H. K. D. H. Bhadeshia, Mat. Sci. Eng. A, 1990, 130, pp. 101-111

ASME Boiler and pressure vessel code: Sec II Part-C: SFA 5.13, The American Society of Mechanical Engineers New York, New York, 2004, pp. 303–24.

S. J Unfried, C.M Garz´onb, J.E Giraldoc: J. Mater. Process. Technol., 2009, Vol. 209, pp. 1688–700.

P. Parameswaran, M. Vijayalakshmi, P. Shankar, V. S. Raghunathan, J. Mater. Sci. 1993, Vol. 28 issue 20, pp. 5426–34.

L. Zhu L., D. Wu, and X.-M. Zhao: J. Iron Steel Res. Int., 2006, vol. 13 (3), pp. 57–60, 73.

R.L.Woodward: Mater Forum, 1988, Vol. 2, pp. 26-30.

M.J. van de Voorde, K. Herlaar, and J.P.F. Broos: Proc. of 23rd Int. Sym. on Ballistics Tarragona, Spain, 2007, pp. 1495–1502.

M. Rabinovich, G. Tivon, G. Yossifon, D. Touati, S. Peles, and M. Arad: Proc. of 23rd Int. Symp. on Ballistics Tarragona, Spain, 2007, pp. 1355–63.

J. Buchar, J. Voldrich, S. Rolc, and J. Lisly: Proc. of 20th Int. Symp. on Ballistics Orlando, FL, 2002, pp. 1–8.

H.K.D.H. Bhadeshia and L.E. Svensson: in Mathematical Modelling of Weld Phenomena, H. Cerjak and K.E. Easterling, eds., Institute of Materials, London, 1993, pp. 109–82.

H.K.D.H. Bhadeshia, L.E Svensson, and B. Gretoft: 4th Scand. Symp. on Mat. Science, Norwegian Institute of Technology, Norway, 1986, pp. 153–58.

Y. Horii, S. Ohkita, M. Wakabayashi, and M. Namura: Nippon Steel Reports, 1986.

Y. Horii, S. Ohkita, M. Wakabayashi, and M. Namura: Nippon Steel Reports, 1988.

Acknowledgments

The authors wish to record their sincere thanks to the Armament Research Board (ARMREB), New Delhi, Government of India, for providing financial support to carry out this investigation through the R&D project No. ARMREB/MAA/2008/93. The authors wish to thank Mailam India Ltd., Pondicherry, for the supply of welding consumables. The authors also express their sincere thanks to Dr. M. Vijayalakshmi, Associate Director, Physical Metallurgy Group, IGCAR, Kalpakkam, for granting permission to use the advanced characterization facilities.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 5, 2013.

Rights and permissions

About this article

Cite this article

Balakrishnan, M., Balasubramanian, V., Madhusudhan Reddy, G. et al. Effect of Capping Front Layer Materials on the Penetration Resistance of Q&T Steel Welded Joints Against 7.62-mm Armor-Piercing Projectile. Metall Mater Trans A 44, 4218–4229 (2013). https://doi.org/10.1007/s11661-013-1794-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-013-1794-8